Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Reaming Machine Operator for Plastic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

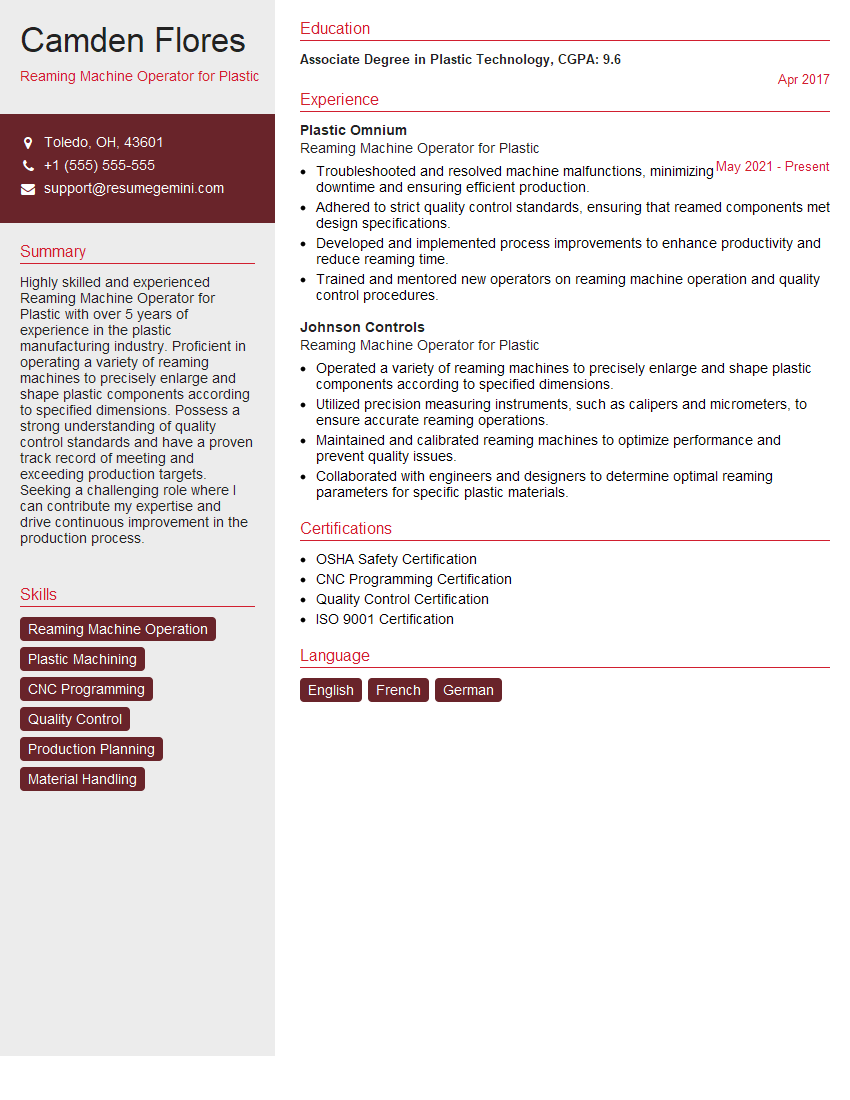

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reaming Machine Operator for Plastic

1. What are the different types of reaming machines used for plastic?

- Horizontal reaming machines

- Vertical reaming machines

- CNC reaming machines

2. What are the factors that affect the accuracy of reaming?

Factors that affect accuracy:

- Tool sharpness

- Machine rigidity

- Workpiece material

- Reaming speed and feed rate

3. How do you set up and operate a reaming machine?

Safety first: Always wear safety glasses and gloves when operating machinery.

- Mount the reamer in the machine spindle

- Set the reaming speed and feed rate

- Position the workpiece under the reamer

- Start the machine and ream the hole

- Stop the machine and remove the workpiece

4. What are the common problems that can occur during reaming?

- Reamer breakage

- Hole size inaccuracy

- Surface finish problems

5. How do you troubleshoot reaming problems?

Troubleshooting:

- Check the reamer for sharpness and damage

- Check the machine settings for accuracy

- Check the workpiece material for compatibility

- Adjust the reaming speed and feed rate as needed

6. What are the different types of reamers used for plastic?

- Tapered reamers

- Straight reamers

- Fluted reamers

7. What are the different types of plastic materials that can be reamed?

- Polyethylene

- Polypropylene

- Polystyrene

8. How do you measure the accuracy of a reamed hole?

- Use a micrometer

- Use a coordinate measuring machine (CMM)

9. What are the safety precautions that must be followed when operating a reaming machine?

Safety first:

- Wear safety glasses and gloves

- Keep hands away from moving parts

- Use a dust collection system

10. What are the quality control procedures that must be followed when reaming plastic parts?

Quality control:

- Inspect the reamed holes for accuracy

- Ensure that the surface finish meets specifications

- Check for any damage to the plastic parts

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reaming Machine Operator for Plastic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reaming Machine Operator for Plastic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Reaming Machine Operator for Plastic is responsible for operating and maintaining a reaming machine used to create holes in plastic components. Key responsibilities include:

1. Machine Operation

Setting up and operating the reaming machine according to specifications.

- Loading and unloading plastic components into the machine.

- Monitoring the machine during operation and making adjustments as needed.

2. Maintenance

Performing routine maintenance on the reaming machine, including cleaning, lubrication, and minor repairs.

- Replacing worn or damaged parts.

- Calibrating the machine regularly to ensure accuracy.

3. Quality Control

Inspecting finished plastic parts to ensure they meet quality standards.

- Measuring the dimensions of the holes.

- Checking for any defects or imperfections.

4. Production

Meeting production targets and deadlines.

- Working efficiently and minimizing downtime.

- Maintaining a clean and organized work area.

Interview Tips

To ace the interview for the Reaming Machine Operator for Plastic position, it’s essential to prepare thoroughly. Here are some interview tips:

1. Research the Company and Position

Before the interview, take the time to research the company, its products, and the specific job requirements. This will help you understand the company culture and the expectations for the role.

- Visit the company website and LinkedIn page.

- Read industry news and articles to stay updated on the latest trends.

2. Practice Your Answers

Think about the common interview questions you may encounter and prepare your answers in advance. Practice delivering your responses clearly and concisely.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Highlight your skills, experience, and accomplishments that are relevant to the job.

3. Demonstrate Your Technical Skills

Be prepared to discuss your technical skills and experience in operating and maintaining reaming machines. You may also be asked to provide examples of your troubleshooting and problem-solving abilities.

- Emphasize your understanding of machine operation principles.

- Share examples of how you have successfully diagnosed and resolved machine issues.

4. Highlight Your Safety and Quality Consciousness

Safety and quality are paramount in manufacturing. In your interview, emphasize your commitment to following safety protocols and adhering to quality standards.

- Describe your experience in adhering to safety regulations and minimizing risks.

- Explain your attention to detail and focus on producing high-quality products.

5. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Dress professionally and arrive on time for your appointment. Be respectful of the interviewer and ask thoughtful questions.

- Express your interest in the position and the company.

- Show that you are eager to contribute your skills and experience to the team.

Next Step:

Now that you’re armed with the knowledge of Reaming Machine Operator for Plastic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Reaming Machine Operator for Plastic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini