Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Reaming Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

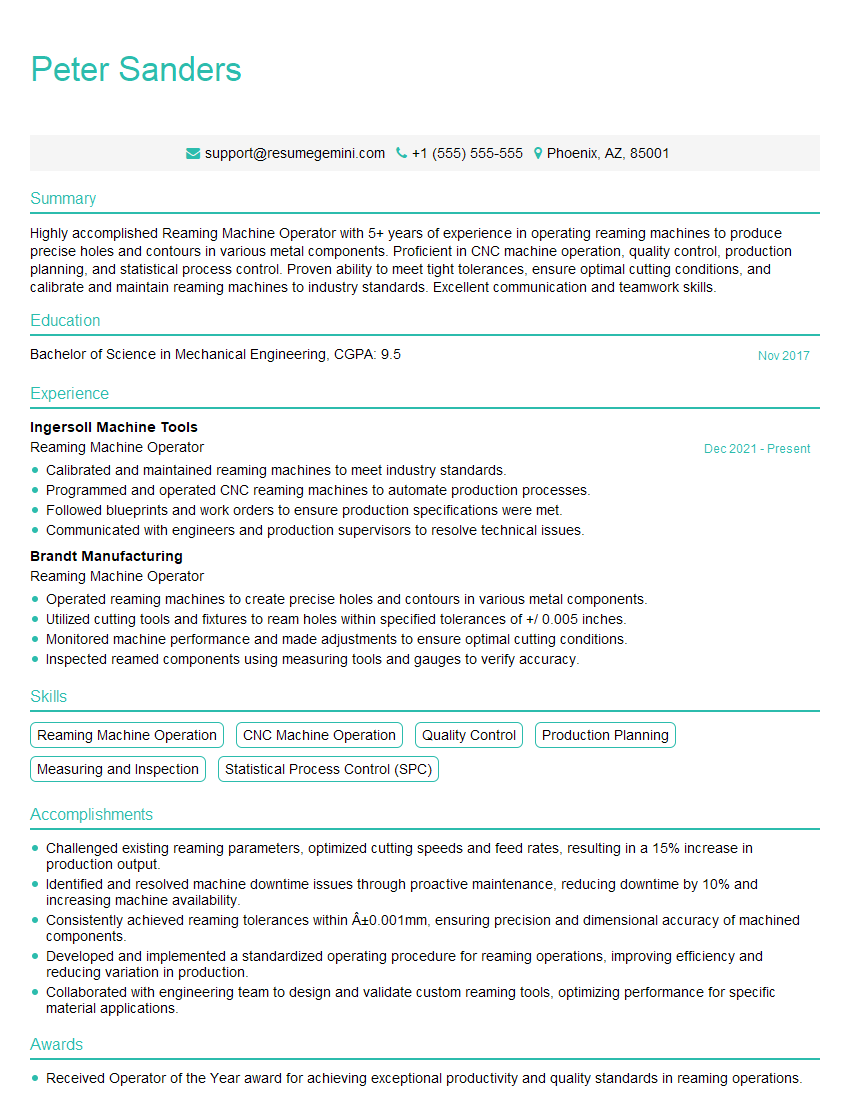

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reaming Machine Operator

1. Describe the process of setting up a reaming machine for a specific operation?

- Inspect the reamer and workpiece to ensure they are compatible.

- Mount the reamer in the machine spindle and secure it.

- Position the workpiece in the fixture and secure it.

- Set the machine speed and feed rate based on the workpiece material and reamer specifications.

- Establish the correct reaming depth and tolerance using gauges or measuring equipment.

- Calibrate the machine tool offsets and zero point to ensure accurate positioning.

- Run a test cut to verify the setup and make any necessary adjustments.

2. How do you inspect a reamed hole to ensure it meets specifications?

Dimensional Inspection

- Use calipers or a micrometer to measure the diameter, depth, and roundness of the hole.

- Compare the measurements to the specified tolerances and determine if the hole is within acceptable limits.

Surface Quality Inspection

- Examine the surface finish of the hole using a microscope or magnifying glass.

- Check for any burrs, scratches, or other defects that may affect the hole’s functionality.

Geometric Inspection

- Check the hole’s concentricity with respect to other features on the workpiece.

- Use a coordinate measuring machine (CMM) or other precision equipment to measure the hole’s geometry.

3. What are the common causes of reaming problems, and how do you troubleshoot them?

- Incorrect Setup: Verify the setup, including reamer selection, workpiece positioning, and cutting parameters.

- Dull or Damaged Reamer: Inspect the reamer for wear or damage and replace it if necessary.

- Excessive Feed Rate: Reduce the feed rate to avoid overloading the reamer and producing chatter.

- Improper Lubrication: Ensure the workpiece and reamer are properly lubricated to reduce friction and prevent overheating.

- Vibration or Chatter: Check the machine for any loose components or imbalances that may cause vibration.

- Workpiece Material Issues: Consider the specific properties of the workpiece material and adjust cutting parameters accordingly.

4. How do you maintain a reaming machine to ensure optimal performance?

Regular maintenance is crucial for optimal reaming performance. Here are some key steps:

- Clean the machine regularly to remove chips, coolant, and other contaminants.

- Lubricate all moving parts according to the manufacturer’s specifications.

- Inspect the spindle, bearings, and other critical components for wear or damage.

- Check the alignment and calibration of the machine regularly.

- Monitor the cutting tools and replace them when necessary.

- Keep a maintenance log to track inspections and repairs.

5. What safety precautions should be taken when operating a reaming machine?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Ensure the machine is properly grounded and all guards are in place.

- Inspect the workpiece and reamer before starting the operation.

- Secure the workpiece firmly to prevent movement during reaming.

- Avoid contact with moving parts and rotating tools.

- Use proper lifting techniques when handling heavy workpieces or reamers.

- Follow lockout/tagout procedures when servicing or repairing the machine.

6. Describe the different types of reaming tools and their applications?

Hand Reamers:

- Used for manual reaming operations, such as finishing holes or removing burrs.

- Types include straight-flute, spiral-flute, and adjustable-blade reamers.

Machine Reamers:

- Used in power-driven machines for high-volume production.

- Types include solid, shell, and adjustable reamers with various cutting geometries and materials.

Special Purpose Reamers:

- Designed for specific applications, such as tapered reaming, thread reaming, or reaming holes with non-circular cross-sections.

7. What are the advantages and disadvantages of using coated cutting tools for reaming?

Advantages:

- Increased tool life and reduced wear.

- Improved surface finish on the workpiece.

- Reduced cutting forces and power consumption.

- Enhanced chip evacuation.

- Extended cutting intervals between re-sharpening.

Disadvantages:

- Higher initial cost compared to uncoated tools.

- Potential for coating delamination or chipping.

- May require specific machining parameters to optimize performance.

8. How do you select the appropriate cutting fluid for reaming operations?

- Consider the workpiece material and its machinability.

- Determine the type of reaming operation (roughing, finishing, etc.).

- Select a cutting fluid that provides lubrication, cooling, and chip removal.

- Choose a fluid that is compatible with the machine and workpiece materials.

- Consider environmental and health and safety regulations.

9. Describe the different methods used to measure the accuracy of a reaming operation?

- Mechanical Measurement: Using precision measuring devices like calipers, micrometers, or coordinate measuring machines (CMMs) to measure the hole’s dimensions and tolerances.

- Optical Measurement: Using optical comparators or microscopes to inspect the hole’s surface finish, geometry, and alignment.

- Inspection Tools: Utilizing specialized inspection tools like hole gauges or plug gauges to verify the hole’s conformance to specific specifications.

- Coordinate Measuring Machines (CMMs): Advanced measuring systems that provide high-precision measurements and detailed reports on the hole’s geometry and dimensions.

10. What are the common industry standards and best practices for reaming operations?

- Follow the manufacturer’s guidelines for the specific reaming machine and tools.

- Adhere to industry standards such as ISO 2768-1 and ANSI B94.55 for reamer tolerances and specifications.

- Use appropriate cutting parameters (speed, feed rate, depth of cut) based on the workpiece material and reamer type.

- Ensure proper lubrication and coolant supply to reduce friction and prolong tool life.

- Regularly inspect and maintain the reaming machine and tools to maintain optimal performance and accuracy.

- Implement quality control measures to monitor the accuracy and consistency of reaming operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reaming Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reaming Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Reaming Machine Operators are responsible for the operation and maintenance of machines used in reaming operations, which involves enlarging or finishing holes in metal components. Their key job responsibilities include:

1. Machine Operation

They set up, operate, and monitor reaming machines according to work orders and engineering specifications.

- Selecting and installing cutting tools and workholding devices.

- Adjusting machine settings for speed, feed, and depth of cut.

- Monitoring the machining process to ensure accuracy and quality.

2. Quality Control

They inspect finished parts using precision measuring instruments to ensure they meet the required dimensions, tolerances, and surface finish.

- Taking measurements using calipers, micrometers, and other tools.

- Verifying compliance with quality standards and specifications.

- Maintaining records of inspection results.

3. Machine Maintenance

They perform routine maintenance on reaming machines to ensure optimal performance and prevent breakdowns.

- Lubricating and cleaning machine components.

- Replacing worn or damaged parts.

- Adjusting or calibrating machine settings.

4. Production Reporting

They keep records of production output, machine downtime, and any issues or concerns encountered during operation.

- Completing work orders and production reports.

- Communicating with supervisors about production status and any problems.

- Maintaining logs of machine usage and maintenance activities.

Interview Tips

To ace the interview for a Reaming Machine Operator position, candidates should prepare by understanding the key job responsibilities and highlighting their relevant skills and experience.

1. Research the Company and Position

Candidates should research the company and the specific reaming machine operator position they are applying for. This will provide them with a better understanding of the company’s culture, business practices, and the specific requirements of the role.

- Visit the company website to learn about their products, services, and recent news.

- Read industry articles and publications to stay updated on reaming machine technology and best practices.

- Connect with company employees on LinkedIn to gain insights into the company culture and work environment.

2. Highlight Relevant Skills and Experience

In the interview, candidates should emphasize their skills and experience that are directly relevant to the job responsibilities of a Reaming Machine Operator. These include:

- Experience operating and maintaining reaming machines.

- Knowledge of precision measurement techniques and quality control procedures.

- Strong attention to detail and accuracy.

- Ability to work independently and follow instructions.

3. Prepare for Common Interview Questions

Candidates should anticipate common interview questions and prepare thoughtful responses. Some common questions include:

- Tell us about your experience operating and maintaining reaming machines.

- Describe your approach to ensuring the accuracy and quality of machined parts.

- How do you stay updated on the latest reaming machine technology and best practices?

- What are your strengths and weaknesses as a Reaming Machine Operator?

4. Be Enthusiastic and Professional

Candidates should demonstrate their enthusiasm for the role and the industry. They should be professional in their demeanor and dress appropriately for the interview. By showing a genuine interest in the position and the company, candidates can make a positive impression on the interviewer.

- Dress professionally and arrive on time for the interview.

- Make eye contact, speak clearly, and answer questions confidently.

- Ask thoughtful questions to show your interest and engagement.

- Thank the interviewer for their time and express your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Reaming Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.