Are you gearing up for a career in Reaming Machine Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Reaming Machine Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

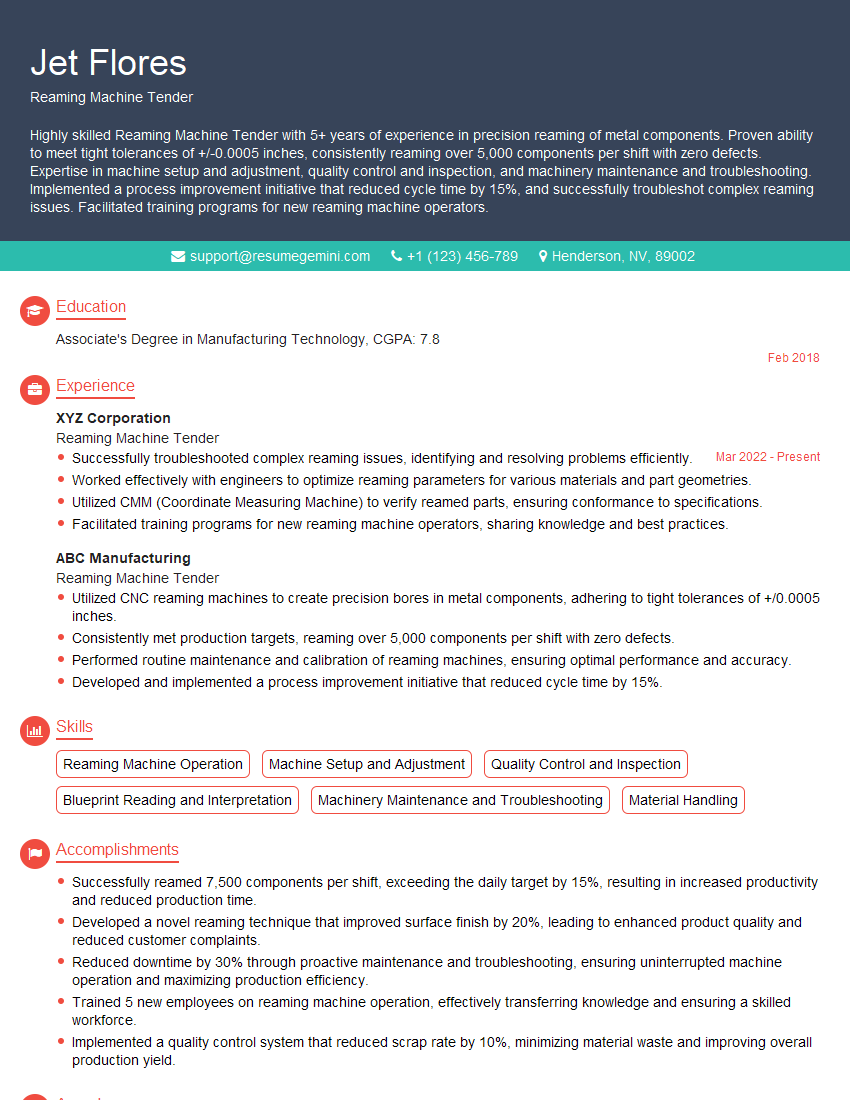

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reaming Machine Tender

1. Explain the process of reaming a hole?

Reaming is a machining process used to enlarge or finish a hole that has already been drilled or cast. The process involves using a reamer, which is a cutting tool with multiple cutting edges, to remove material from the hole and create a smooth, accurate surface.

- The first step in reaming a hole is to select the correct reamer. The reamer should be the same size as the desired hole, and it should have the correct number of cutting edges for the material being machined.

- Once the reamer has been selected, it is inserted into the hole and rotated. The cutting edges of the reamer remove material from the hole as it rotates, creating a smooth, accurate surface.

- The reaming process is typically performed on a drill press or milling machine. The speed of the machine and the feed rate of the reamer are important factors in achieving a good surface finish.

- Once the reaming process is complete, the hole will be to the desired size and surface finish.

2. What are the different types of reamers?

Twist reamers

- Twist reamers are the most common type of reamer. They have a helical flute design that helps to remove chips and cool the reamer.

- Twist reamers are available in a variety of sizes and can be used to ream holes in a variety of materials.

Shell reamers

- Shell reamers are similar to twist reamers, but they have a larger diameter and a shorter flute length.

- Shell reamers are typically used to ream larger holes.

Adjustable reamers

- Adjustable reamers allow the user to adjust the diameter of the hole being reamed.

- Adjustable reamers are typically used for reaming holes to a specific size.

3. What are the factors that affect the accuracy of a reamed hole?

- The accuracy of a reamed hole is affected by a number of factors, including:

- The type of reamer being used

- The condition of the reamer

- The speed of the machine

- The feed rate of the reamer

- The material being machined

- The skill of the operator

- It is important to consider all of these factors when reaming a hole in order to achieve the desired accuracy.

4. What are the common problems that can occur during reaming?

- There are a number of common problems that can occur during reaming, including:

- Reamer chatter

- Reamer breakage

- Hole taper

- Hole bell mouth

- Hole out-of-roundness

- It is important to be aware of these problems and to take steps to prevent them from occurring.

5. What are the safety precautions that should be taken when reaming?

- There are a number of safety precautions that should be taken when reaming, including:

- Wearing proper safety gear, such as safety glasses and gloves

- Ensuring that the machine is properly guarded

- Using sharp reamers

- Reaming at a slow speed

- Using a coolant to keep the reamer and workpiece cool

6. What is the difference between roughing and finishing reaming?

- Roughing reaming is used to remove the majority of the material from a hole.

- Finishing reaming is used to create a smooth, accurate surface finish on a hole.

- Roughing reamers typically have a larger diameter and a shorter flute length than finishing reamers.

- Finishing reamers typically have a smaller diameter and a longer flute length than roughing reamers.

7. What is the difference between a reamer and a drill?

- Reaming is a finishing operation, while drilling is a roughing operation.

- Reamers are used to create smooth, accurate holes, while drills are used to create holes that are not as precise.

- Reaming is typically done at a slower speed than drilling.

8. What is the difference between a reamer and a tap?

- A reamer is a cutting tool used to enlarge or finish a hole, while a tap is a cutting tool used to create threads in a hole.

- Reamers have multiple cutting edges, while taps have a single cutting edge.

- Reaming is typically done at a slower speed than tapping.

9. What are the different types of materials that can be reamed?

- Reaming can be performed on a variety of materials, including:

- Metals

- Plastics

- Wood

- The type of material being reamed will affect the selection of the reamer and the cutting speed.

10. What are the applications of reaming?

- Reaming is used in a variety of applications, including:

- Automotive

- Aerospace

- Medical

- Electronics

- Reaming is a versatile process that can be used to create precise holes in a variety of materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reaming Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reaming Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Reaming Machine Tenders are responsible for operating and monitoring reaming machines, which enlarge or finish holes in metal workpieces. They ensure that the machines are properly set up and operated, and that the workpieces are produced according to specifications.

1. Machine Setup and Operation

Set up and operate reaming machines to enlarge or finish holes in metal workpieces

- Position the workpiece in the machine and secure it in place

- Select and install the appropriate reamer

- Set the machine to the correct speed and feed rate

- Start the machine and monitor its operation

2. Inspection and Measurement

Inspect and measure workpieces to ensure that they meet specifications

- Use precision measuring instruments, such as micrometers and calipers

- Compare the workpiece dimensions to the engineering drawings

- Make adjustments to the machine or workpiece as needed

3. Machine Maintenance

Perform basic maintenance on reaming machines to keep them in good working order

- Clean and lubricate the machine

- Replace worn or damaged parts

- Follow manufacturer’s maintenance instructions

4. Safety

Follow all safety procedures to prevent accidents and injuries

- Wear appropriate safety gear, such as gloves, safety glasses, and earplugs

- Operate the machine in a safe manner

- Keep the work area clean and free of hazards

Interview Tips

Preparing for an interview for a Reaming Machine Tender position requires careful research and practice. Here are some essential tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will give you a better understanding of the company’s culture, values, and what they are looking for in a candidate.

- Visit the company’s website to learn about their history, products, and services.

- Read industry news and articles to stay up-to-date on the latest trends and developments.

- Look for online reviews and testimonials from former employees to get an insider’s perspective on the company.

2. Practice Your Answers

Once you have a good understanding of the company and position, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the actual interview.

- Prepare answers to questions about your experience, skills, and qualifications.

- Think about how your experience and skills align with the requirements of the position.

- Practice your answers out loud so that you can deliver them clearly and confidently.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

- Choose clothes that fit well and are comfortable to wear.

- Avoid wearing clothes that are too revealing, too casual, or too wrinkled.

- Make sure your shoes are clean and polished.

4. Be Punctual

Punctuality shows that you are respectful of the interviewer’s time. Plan your route in advance and leave yourself plenty of time to get to the interview location.

- Aim to arrive at the interview location 10-15 minutes early.

- If you are running late, call or email the interviewer to let them know.

- Do not arrive more than 15 minutes late for the interview.

5. Be Yourself

The most important tip is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest and authentic in your answers.

- Show the interviewer your personality and enthusiasm.

- Be confident in your abilities and qualifications.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Reaming Machine Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Reaming Machine Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.