Feeling lost in a sea of interview questions? Landed that dream interview for Rebar Worker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Rebar Worker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

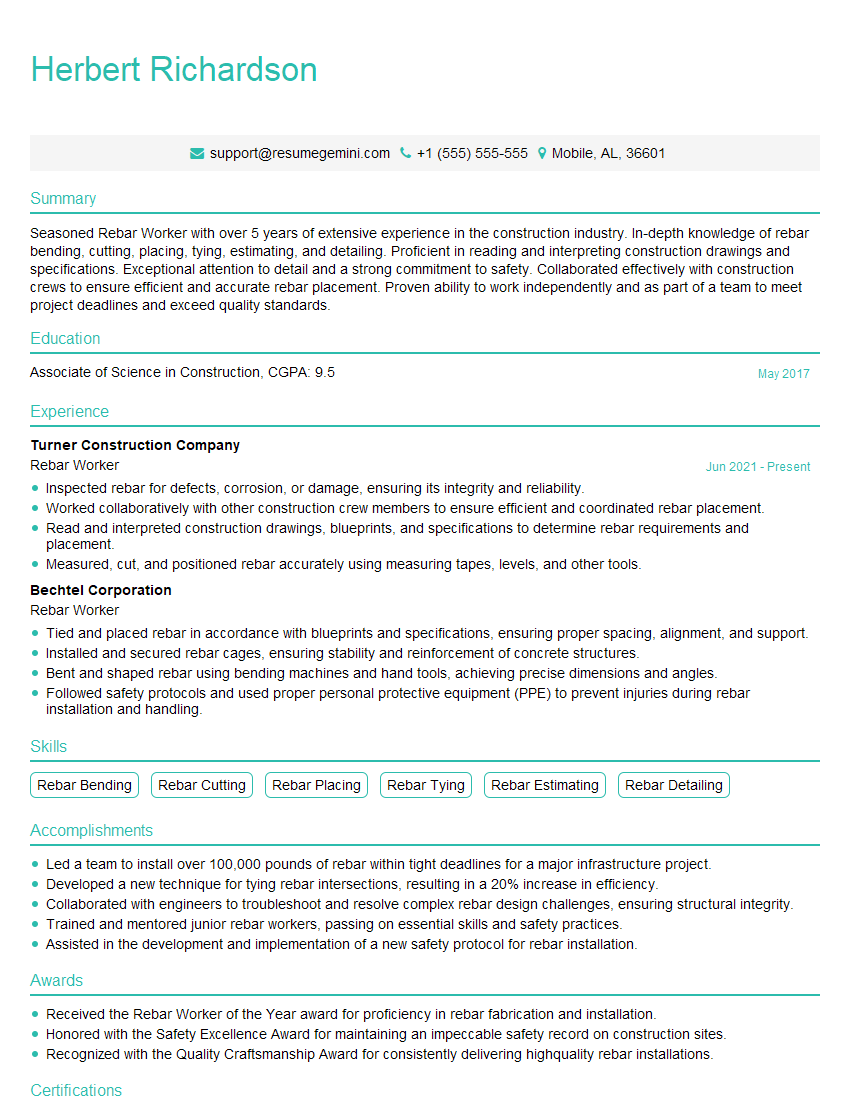

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rebar Worker

1. Describe the process of installing rebar in concrete

The process of installing rebar in concrete involves several steps:

- Preparation: The first step is to prepare the concrete surface by cleaning and leveling it. Forms or molds are set up to shape the concrete structure.

- Positioning: Rebar is then positioned according to the design specifications. This includes bending and shaping the rebar to create the desired reinforcement pattern.

- Tying and Splicing: Rebar is tied together using wire or ties to ensure it remains in place during the concrete pour. Splices are used to connect rebar sections and extend their length.

- Concrete Placement: Concrete is then poured into the forms around the rebar. The concrete is vibrated or consolidated to remove air pockets and ensure proper bonding with the rebar.

- Curing: The concrete is left to cure for a specified period to gain strength and allow the rebar to embed properly.

2. What are the different types of rebar used in construction?

Cold-Drawn Steel Rebar

- High tensile strength

- Used in applications requiring high strength and ductility

Hot-Rolled Steel Rebar

- Lower tensile strength than cold-drawn rebar

- More malleable and easier to bend

Epoxy-Coated Rebar

- Coated with epoxy to protect against corrosion

- Used in areas exposed to harsh environments

Stainless Steel Rebar

- Highly resistant to corrosion

- Used in applications requiring exceptional durability

3. How do you determine the proper spacing and size of rebar?

The proper spacing and size of rebar are determined based on factors such as:

- Structural loads: The rebar must be able to withstand the anticipated loads on the concrete structure.

- Concrete strength: The strength of the concrete influences the amount and spacing of rebar required.

- Codes and regulations: Building codes and standards specify minimum requirements for rebar spacing and size.

- Engineering design: Structural engineers calculate the specific rebar requirements based on the design parameters.

4. What are the common methods of bending rebar?

- Manual bending: Using a rebar bender or a manual jig to shape the rebar.

- Machine bending: Using a specialized rebar bending machine for precise and automated bending.

- Cold bending: Bending rebar at room temperature without heating.

- Hot bending: Heating the rebar before bending to make it more malleable.

5. What safety precautions should be taken when working with rebar?

- Wear appropriate PPE: Hard hat, safety glasses, gloves, and sturdy boots.

- Handle rebar carefully: Use proper lifting techniques and avoid sharp edges.

- Secure rebar properly: Tie or splice rebar securely to prevent it from falling or moving during concrete placement.

- Be aware of surroundings: Pay attention to overhead hazards, tripping hazards, and electrical lines.

- Follow proper lifting procedures: Use mechanical assistance for heavy rebar and avoid overexertion.

6. What are the different tools and equipment used in rebar installation?

- Rebar benders: Used for bending rebar to the desired shape.

- Rebar cutters: Used for cutting rebar to length.

- Tying wire: Used for tying rebar together.

- Splicing devices: Used for connecting rebar sections.

- Concrete vibrators: Used to consolidate concrete and remove air pockets around the rebar.

7. How do you ensure the quality of rebar installation?

- Inspect incoming materials: Verify that rebar meets specifications and is free from defects.

- Follow proper installation procedures: Adhere to design specifications and use appropriate tools and techniques.

- Inspect rebar placement: Ensure that rebar is positioned and tied correctly before concrete placement.

- Test concrete samples: Conduct cylinder tests to ensure concrete strength and bond with the rebar.

- Document the installation process: Keep records of rebar placement and any deviations from specifications.

8. What are the challenges you have faced in rebar installation and how did you overcome them?

Answer with specific examples of challenges encountered on previous projects and the solutions implemented:

- Example: Difficulty bending rebar in tight spaces. Solution: Used a specialized rebar bending machine to achieve precise bends within the space constraints.

- Example: Ensuring proper rebar spacing in complex structures. Solution: Created templates and used measuring devices to accurately position rebar.

9. What are the latest advancements in rebar technology that you are aware of?

- Corrosion-resistant rebar: New coatings and alloys are being developed to improve the durability and longevity of rebar.

- Fiber-reinforced polymer (FRP) rebar: FRP rebar is non-corrosive and lightweight, making it an alternative to steel rebar in certain applications.

- Self-consolidating concrete (SCC): SCC flows easily around rebar, eliminating the need for excessive vibration and improving bond strength.

10. Describe the importance of proper rebar cover in concrete structures.

- Protects rebar from corrosion: Concrete cover provides a barrier between rebar and the environment, preventing moisture and oxygen from reaching it.

- Maintains structural integrity: Adequate concrete cover ensures that rebar is fully embedded in the concrete and can withstand the intended loads.

- Prevents cracking and spalling: Proper cover prevents the concrete from cracking and spalling, which can damage the rebar and weaken the structure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rebar Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rebar Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rebar Worker, plays a crucial role in the construction industry, by performing a wide range of duties related to the placement and fabrication of reinforcing steel bars (rebar) in concrete structures. Their primary responsibilities include:

1. Rebar Installation

Responsible for installing rebar in accordance with construction plans and specifications. This involves accurately positioning, spacing, and tying the rebar to create a strong and durable framework within concrete structures.

- Interpret blueprints and rebar schedules to determine rebar placement and specifications.

- Cut, bend, and shape rebar using specialized tools and equipment.

- Secure rebar using wire ties, welding, or other approved methods.

2. Rebar Fabrication

Involves preparing and assembling rebar components prior to installation. This may include cutting, bending, and welding rebar to create custom shapes and sizes required for specific structural designs.

- Operate rebar fabrication equipment, such as bending machines and shears.

- Assemble rebar cages, stirrups, and other reinforcement components.

- Ensure fabricated rebar meets project specifications and industry standards.

3. Inspection and Quality Control

Rebar Workers are responsible for inspecting and ensuring the quality of their work. This involves checking the accuracy of rebar placement, spacing, and connections. They also ensure that rebar meets specified standards and codes.

- Conduct visual inspections of installed rebar to verify compliance with plans and specifications.

- Measure and record rebar dimensions and spacing to ensure accuracy.

- Report any discrepancies or quality issues to supervisors or engineers.

4. Safety and Hazard Management

Rebar Workers must prioritize safety on the job site. They are responsible for identifying and mitigating potential hazards, such as electrical hazards, falling objects, and sharp edges. They also adhere to safety protocols and regulations.

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and hard hats.

- Operate equipment safely and follow established safety procedures.

- Maintain a clean and organized work area to prevent accidents.

Interview Tips

To ace an interview for a Rebar Worker position, preparation is key. Here are some essential tips:

1. Research the Company and Position

Take time to learn about the construction company and the specific role you are applying for. This will help you tailor your answers and demonstrate your interest in the opportunity.

- Visit the company website and review their projects and services.

- Read industry publications and articles to stay updated on construction trends and best practices.

- Prepare specific questions about the company and the role to show your enthusiasm and engagement.

2. Highlight Relevant Experience and Skills

Emphasize your experience in rebar installation, fabrication, and inspection. Quantify your accomplishments whenever possible to showcase your contributions to previous projects.

- Provide specific examples of complex rebar projects you have worked on.

- Discuss your proficiency in using rebar fabrication equipment and techniques.

- Highlight your understanding of rebar codes and standards.

3. Demonstrate Safety Consciousness

Safety is paramount in construction. Emphasize your commitment to safety by describing your experience in hazard identification and mitigation. Share examples of how you have implemented safety measures on previous projects.

- Explain your knowledge of OSHA regulations and safety protocols.

- Describe how you maintain a safe work environment for yourself and others.

- Discuss your experience in using personal protective equipment.

4. Be Professional and Courteous

Make a positive impression by being punctual, well-dressed, and respectful during the interview. Engage with the interviewer, ask thoughtful questions, and maintain a professional demeanor throughout the process.

- Practice your answers to common interview questions.

- Prepare questions to ask the interviewer that demonstrate your interest.

- Thank the interviewer for their time and consideration.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rebar Worker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.