Are you gearing up for a career in Receiving Manager? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Receiving Manager and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

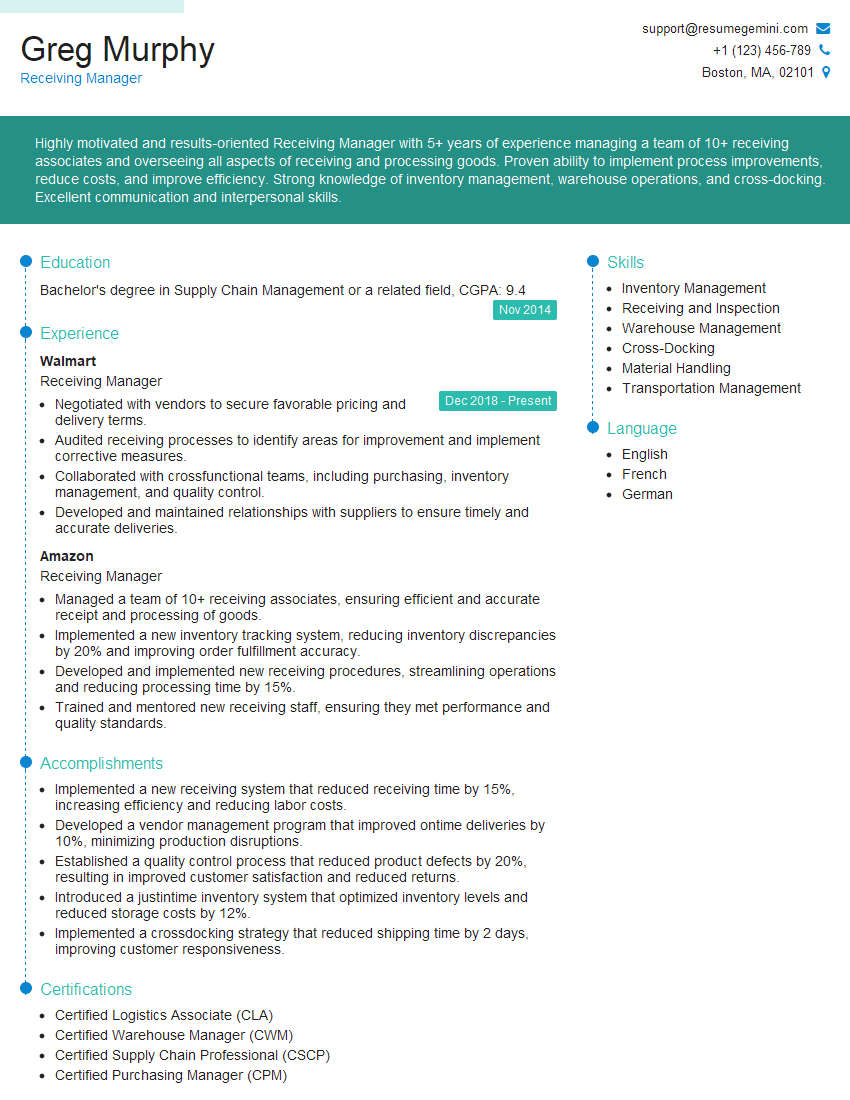

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Receiving Manager

1. How do you plan to improve the accuracy of receiving processes in our warehouse?

To improve the accuracy of receiving processes, I would implement the following measures:

- Conduct thorough training for all receiving staff on proper receiving procedures and documentation.

- Establish clear and standardized receiving protocols, including guidelines for verifying purchase orders, inspecting goods, and handling discrepancies.

- Implement technology such as barcode scanners and RFID readers to automate data capture and minimize human error.

- Regularly monitor and evaluate receiving performance to identify areas for improvement and implement corrective actions.

- Provide ongoing support and training to receiving staff to ensure they have the knowledge and resources they need to perform their duties accurately and efficiently.

2. How would you handle a situation where there is a discrepancy between the quantity of goods received and the quantity listed on the purchase order?

Investigating the discrepancy

- Verify the purchase order and the packing slip to confirm the ordered and received quantities.

- Physically recount the received goods to ensure accuracy.

- Check the condition of the packaging and inspect the goods for any damage or shortages.

Communicating with the supplier

- Contact the supplier and inform them of the discrepancy, providing detailed information about the order and the findings of the investigation.

- Work with the supplier to resolve the issue, including arranging for additional shipments, issuing credits, or returning defective goods.

3. What inventory management techniques do you use to ensure optimal stock levels?

To ensure optimal stock levels, I employ the following inventory management techniques:

- Cycle counting: Regular physical inventory counts to identify and correct discrepancies between actual and recorded inventory levels.

- ABC analysis: Categorizing inventory items based on their value and demand to optimize inventory allocation and storage.

- Just-in-time (JIT) inventory: Minimizing inventory levels by receiving goods only when they are needed for production or sale.

- Safety stock management: Maintaining a buffer stock of critical items to prevent stockouts and ensure uninterrupted operations.

- Inventory forecasting: Using data analysis and historical trends to predict future demand and adjust inventory levels accordingly.

4. How do you prioritize receiving tasks when there are multiple shipments arriving simultaneously?

To prioritize receiving tasks when multiple shipments arrive simultaneously, I consider the following factors:

- Order criticality: Identifying shipments that contain high-priority or time-sensitive items.

- Supplier lead times: Giving priority to shipments from suppliers with longer lead times to avoid potential delays.

- Inventory levels: Prioritizing shipments that replenish critical or low-stock items.

- Shipping method: Considering the delivery time and reliability of different shipping carriers.

- Resource availability: Ensuring that sufficient staff and equipment are available to handle multiple shipments efficiently.

5. How do you ensure that received goods meet quality standards and specifications?

To ensure that received goods meet quality standards and specifications, I implement the following measures:

- Establish clear quality standards: Defining specific criteria and tolerances for acceptable goods.

- Train receiving staff on inspection procedures: Providing thorough training on how to identify and evaluate product defects.

- Implement quality control checks: Establishing random or targeted inspections to verify the quality of received goods against established standards.

- Maintain supplier quality records: Tracking the quality performance of different suppliers to identify and address potential issues.

- Implement supplier improvement programs: Collaborating with suppliers to improve their quality processes and reduce the likelihood of receiving defective goods.

6. How do you manage the storage and handling of hazardous materials?

To effectively manage the storage and handling of hazardous materials, I adhere to the following practices:

- Proper storage: Ensuring hazardous materials are stored in designated, well-ventilated, and compliant areas, away from incompatible substances.

- Safety equipment: Providing and enforcing the use of appropriate personal protective equipment (PPE) for staff handling hazardous materials.

- Spill response plan: Developing and implementing a comprehensive spill response plan to mitigate potential hazards.

- Training and awareness: Regular training for staff on the proper handling, storage, and disposal of hazardous materials.

- Compliance with regulations: Strictly adhering to all applicable federal, state, and local regulations governing the storage and handling of hazardous materials.

7. How do you stay up-to-date with industry best practices and advancements in receiving management?

To stay up-to-date with industry best practices and advancements in receiving management, I engage in the following activities:

- Attend industry conferences and workshops: Participating in educational events to learn about new technologies, trends, and best practices.

- Read industry publications and journals: Subscribing to and regularly reviewing relevant publications to stay informed about industry developments.

- Network with peers and experts: Connecting with professionals in the field through industry organizations or online forums to exchange ideas and share knowledge.

- Conduct research and analysis: Proactively seeking out and analyzing industry data, case studies, and research findings to identify opportunities for improvement.

- Implement pilot programs: Testing and evaluating innovative solutions to receiving management challenges before full-scale implementation.

8. How do you measure and evaluate the performance of the receiving department?

To measure and evaluate the performance of the receiving department, I use the following key performance indicators (KPIs):

- Receiving accuracy: Percentage of goods received without discrepancies or errors.

- Cycle time: Average time it takes to receive, inspect, and process goods.

- Inventory accuracy: Consistency between physical inventory counts and recorded inventory levels.

- Supplier performance: On-time delivery, quality, and responsiveness of suppliers.

- Receiving costs: Total expenses associated with receiving operations, including labor, equipment, and supplies.

9. How do you handle and resolve receiving discrepancies with suppliers?

Investigating the discrepancy

- Verify the purchase order, packing slip, and received goods to identify the source of the discrepancy.

- Contact the supplier and provide detailed information about the discrepancy, including documentation and evidence.

Resolving the issue

- Work with the supplier to determine the root cause of the discrepancy and develop corrective actions.

- Negotiate and agree on a resolution, such as issuing credits, replacing defective goods, or adjusting the purchase order.

- Document the resolution and follow up to ensure that the issue is resolved effectively.

10. How do you leverage technology to improve the efficiency and effectiveness of receiving operations?

To leverage technology to improve the efficiency and effectiveness of receiving operations, I implement the following solutions:

- Barcode scanning and RFID: Automating data capture and reducing manual entry errors.

- Inventory management software: Centralizing inventory data, tracking stock levels, and generating reports.

- Warehouse management systems (WMS): Optimizing receiving processes, managing inventory, and providing real-time visibility.

- Electronic data interchange (EDI): Automating the exchange of purchase orders, invoices, and other documents with suppliers.

- Mobile devices: Empowering receiving staff with handheld devices to access information and perform tasks on the go.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Receiving Manager.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Receiving Manager‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Receiving Manager plays a pivotal role in the smooth operation of a warehouse or distribution center. Key job responsibilities include:

1. Inventory Management

Oversee the receipt, inspection, and storage of incoming goods.

- Ensure inventory accuracy through regular counts and reconciliations.

- Monitor inventory levels and coordinate with suppliers to ensure timely replenishment.

2. Receiving Operations

Supervise the receiving team and ensure efficient unloading and handling of incoming shipments.

- Establish and maintain receiving procedures and protocols.

- Inspect goods for damage or discrepancies and document any issues.

3. Warehouse Operations

Collaborate with warehouse management to optimize storage and retrieval processes.

- Assign storage locations and implement inventory control systems.

- Ensure the proper handling and storage of goods to maintain quality and prevent damage.

4. Supplier Management

Maintain relationships with suppliers and coordinate the receipt of goods.

- Negotiate and manage supplier contracts for receiving services.

- Monitor supplier performance and address any issues or delays.

Interview Tips

To ace an interview for the Receiving Manager position, consider the following tips:

1. Highlight Experience and Skills

Emphasize your experience in receiving operations, inventory management, and warehouse logistics.

- Quantify your achievements by providing specific examples of how you improved efficiency or reduced costs.

- Demonstrate your proficiency in inventory control systems and warehouse management techniques.

2. Showcase Leadership Abilities

Receiving Managers often supervise teams. Highlight your leadership skills and ability to motivate and manage others.

- Describe instances where you successfully led a team, resolved conflicts, or improved team performance.

- Emphasize your ability to work effectively with diverse stakeholders, including suppliers and warehouse personnel.

3. Discuss Problem-Solving Skills

Receiving Managers often encounter unexpected challenges. Showcase your problem-solving abilities.

- Provide examples of how you identified and resolved issues in receiving operations, inventory management, or supplier relationships.

- Highlight your analytical skills and ability to make data-driven decisions.

4. Stay Up-to-Date on Industry Trends

Express your knowledge of the latest trends and best practices in receiving and warehouse management.

- Discuss your understanding of automation, technology, and sustainability initiatives in the industry.

- Show that you are eager to stay informed and adopt new technologies to improve operations.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Receiving Manager interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!