Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Reclamation Furnace Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

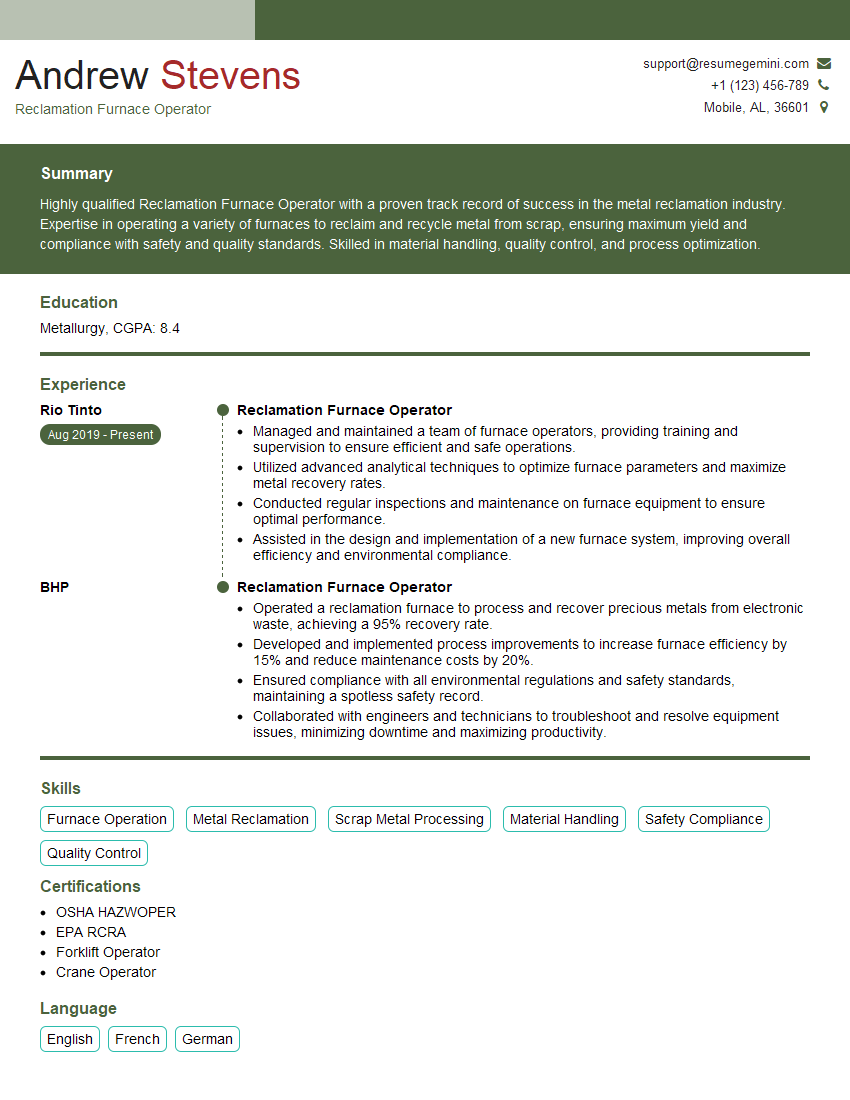

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reclamation Furnace Operator

1. What are the primary responsibilities of a Reclamation Furnace Operator?

Ensuring the safe and efficient operation of a reclamation furnace, including:

- Preparing and feeding scrap metal into the furnace

- Monitoring and controlling furnace temperature and atmosphere

- Tapping and casting molten metal into ingots or other forms

- Performing maintenance on the furnace and ancillary equipment

- Adhering to safety regulations and procedures

2. Describe the key technical skills required for a Reclamation Furnace Operator.

Metallurgical Knowledge

- Understanding of metal properties and alloys

- Knowledge of metal melting and casting processes

- Experience with different types of furnaces (e.g., arc furnaces, induction furnaces)

Equipment Operation

- Proficiency in operating furnaces, material handling equipment, and auxiliary systems

- Ability to troubleshoot equipment malfunctions and perform basic repairs

- Experience in using instrumentation and control systems

3. How do you monitor and control the temperature of a reclamation furnace?

Monitoring temperature involves using thermocouples or pyrometers to measure the temperature of the furnace at various locations. Controlling temperature involves adjusting fuel flow, air flow, and other process parameters to maintain the desired temperature profile.

4. What are the potential hazards associated with operating a reclamation furnace, and how do you mitigate them?

Potential hazards include:

- Extreme heat and molten metal

- Toxic gases and fumes

- Mechanical equipment

- Electrical hazards

Mitigation measures include:

- Wearing appropriate personal protective equipment (PPE)

- Following safety procedures

- Regular equipment maintenance and inspections

- Proper ventilation and exhaust systems

5. How do you ensure the quality of the molten metal produced by the reclamation furnace?

Quality control involves sampling and analyzing molten metal to ensure it meets specifications. This may include testing for chemical composition, physical properties, and impurities. Adjustments to the furnace process or charge materials may be necessary to achieve the desired quality.

6. Describe the steps involved in tapping and casting molten metal from a reclamation furnace.

Tapping involves opening a taphole in the furnace to allow molten metal to flow into a ladle. Casting involves pouring molten metal from the ladle into molds or other forms to create ingots or other desired shapes.

7. What are the environmental regulations and safety standards that apply to the operation of a reclamation furnace?

Compliance with environmental regulations and safety standards is crucial. These may include:

- Emission limits for air pollutants and hazardous materials

- Requirements for proper waste disposal

- OSHA and industry safety guidelines

8. How do you troubleshoot problems with a reclamation furnace?

Troubleshooting involves identifying the source of the problem by observing symptoms, checking instrumentation, and performing diagnostic tests. Common problems include temperature control issues, equipment malfunctions, and process inefficiencies. Troubleshooting requires a combination of technical knowledge, experience, and problem-solving skills.

9. What is your experience with lean manufacturing principles and continuous improvement?

Lean manufacturing principles focus on improving efficiency and reducing waste. Continuous improvement involves ongoing efforts to identify and eliminate inefficiencies in processes. Experience with these principles can help optimize furnace operation and enhance productivity.

10. How do you stay abreast of new technologies and advancements in the field of reclamation furnace operation?

Keeping up with advancements is important for optimizing furnace performance. This can involve attending industry conferences, reading trade publications, and participating in training programs. Staying informed about new technologies and best practices can also lead to innovation and process improvements.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reclamation Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reclamation Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Reclamation Furnace Operators possess a diverse range of responsibilities that encompass the entire reclamation process, including:

1. Furnace Operation and Maintenance

Operate and control furnaces, ensuring adherence to process parameters and quality standards.

- Monitor and adjust furnace temperatures, pressures, and other operating conditions.

- Perform routine inspections and preventive maintenance to ensure optimal furnace performance.

2. Raw Material Preparation and Feeding

Prepare and load raw materials into the furnace according to established specifications.

- Weigh, measure, and blend raw materials to create the appropriate composition for the reclamation process.

- Operate mechanical feeding systems to convey raw materials into the furnace.

3. Process Monitoring and Control

Monitor and control the reclamation process to ensure efficient and safe operations.

- Observe and interpret furnace readings, such as temperature, pressure, and gas flow.

- Adjust process parameters to maintain optimal conditions and prevent deviations from quality standards.

4. Product Handling and Quality Control

Remove and handle the reclaimed product, ensuring adherence to safety protocols and quality standards.

- Operate equipment to discharge reclaimed product from the furnace and transfer it to storage or further processing.

- Inspect and test reclaimed product to verify compliance with specifications.

Interview Tips

To ace the interview for a Reclamation Furnace Operator position, preparing thoroughly and showcasing your relevant skills and experience is crucial. Consider the following tips:

1. Research the Company and Role

Thoroughly research the company, its operations, and the specific role you are applying for. This will demonstrate your interest and preparation.

- Visit the company website, read industry publications, and check social media platforms for updates.

- Analyze the job description carefully to identify the key responsibilities and qualifications.

2. Highlight Relevant Experience

Focus on highlighting your previous experience in furnace operations, materials handling, and quality control. Quantify your accomplishments whenever possible.

- Describe your involvement in operating and maintaining furnaces, including the types of furnaces you worked with.

- Discuss your experience in preparing and feeding raw materials, as well as your knowledge of process parameters.

3. Emphasize Safety and Quality Awareness

Reclamation Furnace Operators must prioritize safety and quality. Emphasize your understanding and adherence to safety protocols and quality standards.

- Describe your knowledge of industry regulations and best practices.

- Explain how you ensured the quality of reclaimed products by monitoring and testing.

4. Prepare for Technical Questions

Be prepared to answer technical questions related to furnace operations, raw material handling, and product testing. Review common furnace types, materials used in reclamation, and quality control techniques.

- Practice answering questions about temperature control, material composition, and troubleshooting furnace issues.

- Research testing methods and specifications to demonstrate your understanding of product quality.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Reclamation Furnace Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!