Are you gearing up for an interview for a Reclamation Kettle Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Reclamation Kettle Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

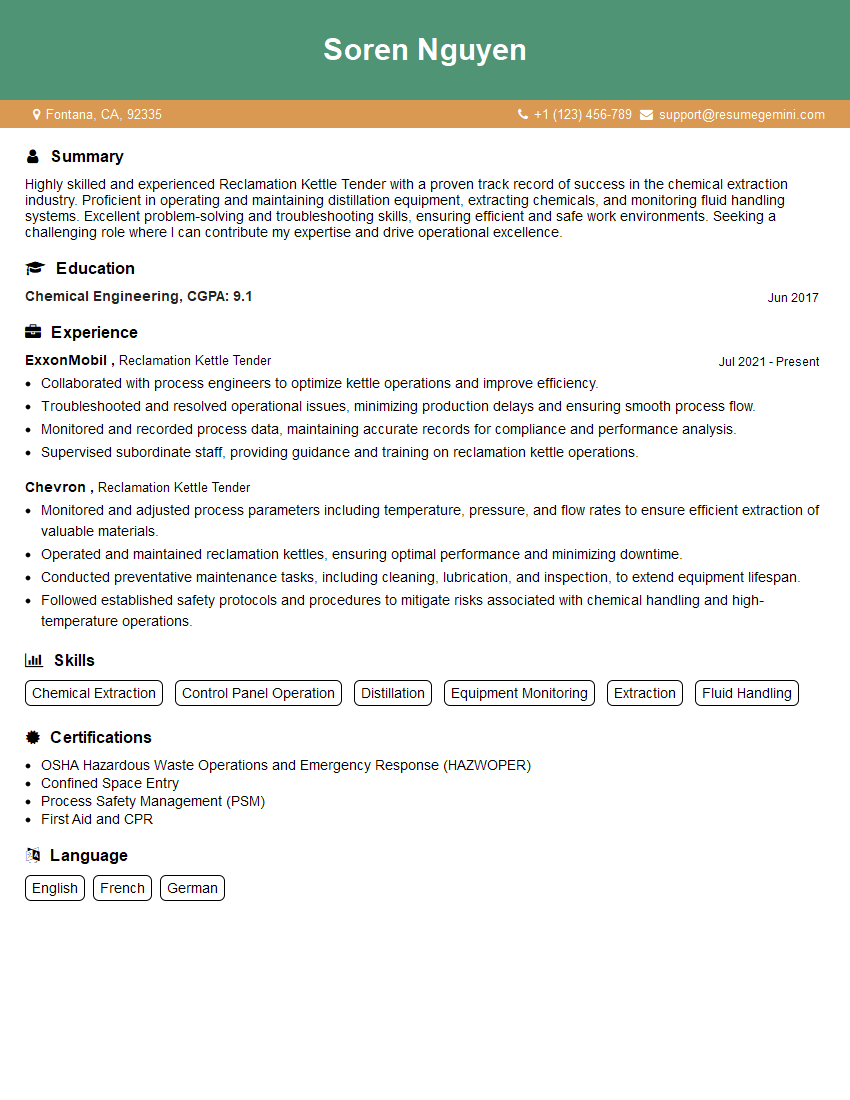

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reclamation Kettle Tender

1. Explain the key responsibilities of a Reclamation Kettle Tender?

As a Reclamation Kettle Tender, my primary responsibilities include:

- Operating and maintaining reclamation kettles to recover and purify asphalt binder

- Monitoring and controlling the temperature, pressure, and flow rates of the reclamation process

- Performing routine inspections and maintenance on equipment, including pumps, tanks, and filters

- Ensuring that all safety protocols and regulations are strictly followed

- Working closely with other team members and supervisors to ensure efficient operations

2. Describe the key safety considerations when operating a reclamation kettle?

Maintaining a clean and organized work area

- Eliminate tripping hazards and keep equipment free of debris

- Store chemicals and materials properly to prevent spills and leaks

Proper handling of hot materials

- Wear appropriate protective gear, including heat-resistant gloves and clothing

- Use proper tools and techniques to handle hot asphalt binder

Monitoring equipment conditions

- Inspect equipment regularly for signs of wear, damage, or leaks

- Follow maintenance schedules and report any issues promptly

3. How do you monitor and control the temperature and pressure of the reclamation process?

To monitor and control the temperature and pressure of the reclamation process, I use a combination of instruments and techniques:

- Temperature sensors: I install temperature sensors at critical points in the system to monitor the temperature of the asphalt binder

- Pressure gauges: I use pressure gauges to monitor the pressure in the kettle and piping system

- Control valves: I adjust control valves to regulate the flow of asphalt binder and heat transfer fluid, which helps maintain the desired temperature and pressure

- Data logging: I use data logging equipment to record temperature and pressure readings over time, which allows me to track trends and identify potential issues

4. What are the common troubleshooting procedures for a malfunctioning reclamation kettle?

When a reclamation kettle malfunctions, I follow a systematic troubleshooting procedure to identify and resolve the issue:

- Check for power: I verify that the kettle is receiving power and that all electrical connections are secure

- Inspect for leaks: I check for any leaks in the kettle, piping, or valves

- Examine the burner: I inspect the burner to ensure that it is functioning properly and that the flame is stable

- Monitor temperature and pressure: I monitor the temperature and pressure readings to identify any deviations from normal operating parameters

- Consult manuals and documentation: I refer to the kettle’s operation and maintenance manuals for specific troubleshooting guidance

5. How do you ensure that the reclaimed asphalt binder meets the desired specifications?

To ensure that the reclaimed asphalt binder meets the desired specifications, I perform the following steps:

- Sample collection: I collect representative samples of the reclaimed asphalt binder at regular intervals

- Testing: I conduct various tests on the samples, such as penetration, viscosity, and softening point, to evaluate their properties

- Data analysis: I compare the test results to the specified requirements

- Adjustments: If the test results do not meet the specifications, I make adjustments to the reclamation process, such as modifying the temperature or pressure, to improve the quality of the reclaimed binder

6. Describe the different types of asphalt binders and their applications

There are various types of asphalt binders used in pavement construction, each with unique properties and applications:

- Penetration-graded asphalt binder: This type of binder is graded according to its penetration depth, which indicates its hardness. It is commonly used in hot mix asphalt pavements

- Performance-graded asphalt binder: This type of binder is graded based on its performance characteristics, such as rutting resistance and fatigue resistance. It is designed to meet specific performance requirements for different traffic and climate conditions

- Modified asphalt binder: This type of binder is enhanced with polymers or other additives to improve its properties, such as flexibility, adhesion, and durability. It is often used in specialized applications, such as airport pavements and bridge decks

- Cutback asphalt binder: This type of binder is blended with solvents to reduce its viscosity, making it easier to apply. It is commonly used in cold weather applications and for patching and repair work

7. Explain the principles of asphalt pavement recycling and the benefits it offers

Asphalt pavement recycling involves reusing old asphalt materials to create new pavements. It offers several benefits:

- Environmental sustainability: Recycling asphalt reduces the need for new materials and helps preserve natural resources

- Cost-effectiveness: Recycled asphalt is often less expensive than new materials, leading to significant cost savings

- Improved performance: Recycled asphalt pavements can have enhanced durability and performance characteristics compared to pavements made entirely from new materials

- Reduced emissions: Recycling asphalt reduces the energy required for production and transportation, which lowers greenhouse gas emissions

8. Describe the potential challenges associated with operating a reclamation kettle and how you would overcome them

Operating a reclamation kettle can present various challenges, but I have developed strategies to overcome them:

- Extreme temperatures: Reclamation kettles operate at high temperatures, which can be physically demanding. I wear appropriate protective gear and take regular breaks to avoid heat-related issues

- Noise levels: The operation of a reclamation kettle can generate significant noise. I use hearing protection to minimize the impact on my hearing

- Fumes and odors: The reclamation process can release fumes and odors. I ensure proper ventilation and wear a respirator when necessary to protect my respiratory health

- Equipment breakdowns: Equipment malfunctions can occur. I am trained to perform basic troubleshooting and repairs, and I promptly report any major issues to my supervisor

9. Explain the importance of preventive maintenance for reclamation kettles and how you ensure it is effectively implemented

Preventive maintenance is crucial for the longevity and efficiency of reclamation kettles. I implement a comprehensive maintenance program that includes:

- Regular inspections: I conduct regular inspections to identify potential issues early on

- Scheduled maintenance tasks: I perform scheduled maintenance tasks, such as cleaning, lubrication, and adjustments, to keep the kettle in good working order

- Record keeping: I maintain detailed records of all maintenance activities, which helps me track the kettle’s performance and identify areas for improvement

- Collaboration with maintenance personnel: I work closely with maintenance personnel to ensure that all necessary repairs and upgrades are performed promptly

10. Discuss the advancements in asphalt recycling technology and how they impact your role as a Reclamation Kettle Tender

Advancements in asphalt recycling technology are continuously evolving, and I actively stay updated on these advancements to improve my skills:

- Improved equipment: Newer reclamation kettles are more efficient and have advanced features that enhance the recycling process

- New recycling techniques: Emerging recycling techniques, such as cold recycling and asphalt emulsion recycling, require specialized knowledge and skills

- Sustainability initiatives: The increasing focus on sustainability has led to the development of environmentally friendly recycling methods, which I am eager to embrace

- Data analytics: Data analytics tools can be used to optimize the recycling process, and I am exploring ways to incorporate them into my work

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reclamation Kettle Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reclamation Kettle Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Reclamation Kettle Tender is responsible for ensuring efficient chemical reclamation and handling systems.

1. Chemical Reclamation

The key objective is to maintain a safe and efficient chemical reclamation system. Which includes:

- Operating and monitoring chemical reclamation processes

- Ensuring that chemical concentrations meet specifications

- Performing regular cleaning and maintenance of equipment

- Troubleshoot and resolve any malfunctions

2. Chemical Handling

The role requires the proper handling and storage of chemicals. This involves:

- Preparing and mixing different chemicals as per requirements

- Inspecting and replacing chemical containers

- Adhering to safety guidelines and regulations

- Maintaining accurate records of chemical usage

3. Equipment Maintenance

Regular upkeep and maintenance of all systems and equipment are necessary. This includes:

- Cleaning and inspecting equipment for any wear or damage.

- Performing preventive maintenance on a regular basis

- Troubleshooting and repairing minor issues

- Coordinating with maintenance personnel for major repairs or replacements

4. Safety and Compliance

Ensuring a safe work environment and adhering to industry standards is crucial. This involves:

- Following all safety protocols and guidelines

- Using appropriate personal protective equipment (PPE)

- Maintaining a clean and organized work area

- Complying with environmental regulations

Interview Tips

To ace the interview for the Reclamation Kettle Tender position, here are some valuable tips:

1. Research the Company and Position

Before the interview, thoroughly research the company’s background and the specific requirements of the position. This will demonstrate your interest in the opportunity and help you tailor your answers accordingly.

- Visit the company’s website to learn about its products, services, and culture.

- Review the job description carefully and identify the key skills and qualifications required.

2. Highlight Relevant Experience and Skills

During the interview, emphasize your previous experience and skills that directly align with the responsibilities of the Reclamation Kettle Tender role. Provide specific examples to showcase your proficiency in:

- Chemical reclamation operations

- Chemical handling and storage

- Equipment maintenance and repair

- Safety compliance and regulations

3. Demonstrate Attention to Detail and Problem-Solving Abilities

Reclamation Kettle Tenders must be detail-oriented and possess strong problem-solving skills. Highlight instances where you meticulously followed procedures, identified issues proactively, and implemented effective solutions.

- Describe a situation where you successfully diagnosed and resolved a malfunction in a chemical reclamation system.

- Provide an example of how your attention to detail helped prevent a potential safety hazard.

4. Emphasize Teamwork and Communication Skills

Reclamation Kettle Tenders often work as part of a team and interact with other departments. Demonstrate your ability to collaborate effectively, communicate clearly, and build positive relationships with colleagues.

- Share an example of how you successfully collaborated with colleagues to streamline a chemical handling process.

- Describe a situation where you effectively communicated technical information to non-technical team members.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Reclamation Kettle Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Reclamation Kettle Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.