Are you gearing up for a career in Record Press Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Record Press Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

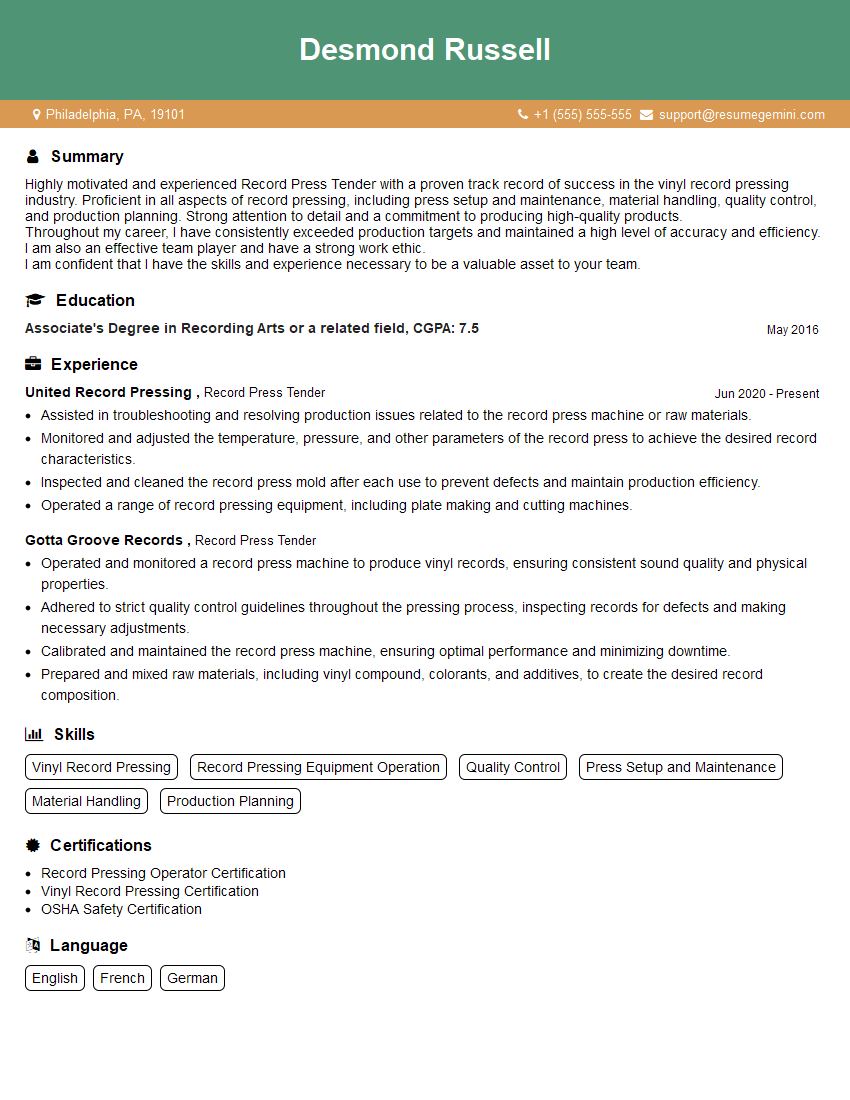

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Record Press Tender

1. How can you ensure the quality of the records pressed using the machines and materials available?

To ensure the quality of the records pressed, I would carry out the following steps:

– Meticulously inspect the materials: Regularly check the condition of the pressing machines, molds, and materials to ensure they meet the required standards.

– Optimize machine settings: Calibrate and adjust machine settings, such as temperature, pressure, and speed, to achieve optimal pressing conditions for the specific record material.

– Implement quality control procedures: Establish clear quality control procedures to identify and reject any defective records during and after the pressing process.

– Monitor environmental factors: Control the temperature and humidity levels in the pressing environment to prevent warping or other quality issues.

– Seek feedback and make adjustments: Regularly gather feedback from customers and industry professionals to identify areas for improvement and make necessary adjustments to the pressing process.

2. Describe the essential safety precautions you follow when operating record pressing machines.

Adhering to safety protocols:

- Always wear appropriate safety gear, including earplugs, safety glasses, and gloves.

- Thoroughly inspect equipment before operation to identify any potential hazards.

- Ensure the work area is well-lit and free from tripping hazards or obstructions.

- Never operate machines without proper training and authorization.

Safe operation practices:

- Maintain a safe distance from moving parts and hot surfaces.

- Use proper techniques when loading and unloading records to prevent injuries.

- Be aware of the potential for high-pressure steam or fluid leaks.

- Report any safety concerns or incidents immediately to supervisors.

3. How do you troubleshoot common issues encountered during the record pressing process?

To effectively troubleshoot common issues encountered during the record pressing process, I employ the following strategies:

– Identify the issue: Observe the pressing process and identify the specific problem, whether it’s poor sound quality, surface imperfections, or production delays.

– Analyze potential causes: Consider various factors that may contribute to the issue, such as faulty equipment, incorrect settings, or material defects.

– Consult technical documentation: Refer to manufacturer’s manuals, industry resources, or consult with experienced professionals to gather insights and potential solutions.

– Implement corrective actions: Based on the analysis, I systematically implement corrective measures, such as adjusting machine parameters, replacing faulty components, or refining the pressing process.

– Monitor and evaluate: After implementing corrective actions, I closely monitor the results and make further adjustments as necessary to ensure the issue is resolved.

4. Explain the importance of maintaining accurate records and documentation throughout the record pressing process.

Maintaining accurate records and documentation throughout the record pressing process is crucial for several reasons:

– Quality control: Documentation allows for detailed tracking of each pressing run, including raw materials used, machine settings, and quality control checks. This facilitates the identification of potential issues and helps maintain consistent product quality.

– Traceability: In case of any quality concerns or customer inquiries, having comprehensive records enables us to trace the production process and identify the source of the issue.

– Process optimization: By reviewing historical data, we can analyze trends, identify areas for improvement, and optimize the pressing process to enhance efficiency and reduce waste.

– Compliance: Accurate records demonstrate compliance with industry standards and regulatory requirements, ensuring the integrity of the pressing process.

– Knowledge sharing: Well-documented processes facilitate knowledge sharing within the team and serve as a valuable resource for training new employees.

5. Describe your experience in utilizing different types of record pressing machines.

Throughout my career, I have gained extensive experience in operating various types of record pressing machines, including:

– Manual presses: I am proficient in manually setting up and operating mechanical presses, ensuring precise pressure and temperature control for small-batch or custom pressings.

– Semi-automatic presses: I have experience operating semi-automatic presses that offer increased efficiency and consistency in pressing large quantities of records.

– Fully-automatic presses: I am familiar with the operation of fully-automatic presses that handle the entire pressing process with minimal manual intervention, resulting in high-volume production.

6. How do you manage the production schedule to ensure timely delivery of record orders?

To ensure timely delivery of record orders, I effectively manage the production schedule through the following practices:

– Prioritization: I prioritize orders based on deadlines and customer requirements, ensuring that urgent orders receive immediate attention.

– Capacity planning: I assess the production capacity and allocate resources accordingly to meet the scheduled delivery dates.

– Monitoring progress: I regularly monitor the progress of each order, identifying potential bottlenecks and taking proactive steps to mitigate delays.

– Communication: I maintain open communication with customers, providing updates on order status and any anticipated delays.

– Contingency planning: I develop contingency plans to address unforeseen circumstances that may impact the production schedule.

7. Explain the steps involved in setting up and calibrating a record pressing machine.

Setting up and calibrating a record pressing machine involves the following steps:

– Machine preparation: I thoroughly clean and inspect the machine, ensuring all components are in good condition and properly lubricated.

– Mold installation: I carefully install the appropriate mold set for the desired record size and format.

– Temperature calibration: I calibrate the heating elements to achieve the precise temperature required for the specific record material.

– Pressure adjustment: I adjust the pressure settings to ensure optimal pressure is applied during the pressing process.

– Speed optimization: I set the pressing speed to match the material properties and desired record quality.

– Test pressing: I perform a test pressing to verify the machine settings and make any necessary fine-tuning.

8. How do you ensure the proper maintenance and care of record pressing equipment?

To ensure the proper maintenance and care of record pressing equipment, I strictly adhere to the following practices:

– Regular cleaning: I routinely clean all machine components, including molds, platens, and pressing surfaces, to prevent buildup of debris or contaminants.

– Lubrication: I lubricate moving parts and bearings according to the manufacturer’s recommendations to minimize friction and wear.

– Calibration checks: I periodically check and calibrate the machine’s temperature, pressure, and speed settings to ensure optimal performance.

– Preventive maintenance: I perform regular preventive maintenance tasks, such as checking belts, hoses, and electrical connections, to identify and address potential issues before they become major problems.

– Record keeping: I maintain detailed maintenance records, including dates of inspections, repairs, and replacements, for future reference.

9. Explain the different types of record materials and their pressing requirements.

There are several types of record materials, each with its own unique pressing requirements:

– Vinyl (PVC): Vinyl records require specific temperature and pressure settings during pressing to achieve the desired sound quality and durability.

– Shellac: Shellac records are made from a natural resin and require higher temperatures and pressures compared to vinyl.

– Polycarbonate: Polycarbonate records are known for their durability and resistance to warping, requiring different pressing parameters than vinyl.

– Recycled materials: Some record manufacturers use recycled materials, which may have unique pressing requirements to ensure quality and consistency.

– Custom blends: Custom blends of materials can be used to create records with specific characteristics, requiring tailored pressing conditions.

10. Describe the process of quality control for pressed records.

Quality control for pressed records involves several key steps:

– Visual inspection: Records are visually inspected for defects such as scratches, surface imperfections, or off-center pressings.

– Audio testing: Records are played to assess sound quality, including checking for skips, pops, or noise.

– Weight and thickness measurements: Records are weighed and measured to ensure they meet the specified standards.

– Packaging inspection: Record sleeves and jackets are inspected for damage or defects before packaging.

– Documentation: Detailed records are kept of all quality control checks, including any rejected records and the reasons for rejection.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Record Press Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Record Press Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Record Press Tenders are responsible for operating record presses to produce vinyl records. Their key job responsibilities include:

1. Machine Operation

Setting up and operating record presses to produce vinyl records according to specifications.

- Loading and unloading raw materials into and from the press.

- Monitoring machine operation and making adjustments as needed.

- Ensuring that the records are produced to the required quality standards.

2. Quality Control

Inspecting records for defects and ensuring that they meet quality standards.

- Checking for surface defects, such as scratches or bubbles.

- Checking for sound quality, such as clicks or pops.

- Rejecting records that do not meet quality standards.

3. Maintenance

Performing basic maintenance on record presses, including cleaning and lubrication.

- Monitoring machine performance and identifying potential problems.

- Performing routine maintenance tasks, such as cleaning and oiling.

- Reporting major problems to supervisors.

4. Safety

Following all safety procedures and wearing appropriate safety gear.

- Ensuring that the work area is clean and free of hazards.

- Wearing appropriate safety gear, such as gloves and safety glasses.

- Reporting any accidents or injuries to supervisors.

Interview Tips

To ace an interview for a Record Press Tender position, it is important to be prepared and to demonstrate your knowledge of the job responsibilities. Here are some tips to help you prepare for your interview:

1. Research the company and the position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, social media pages, and Glassdoor.

- Research the company’s history, mission, and values.

- Read the job description carefully and identify the key requirements.

- Check the company’s social media pages to get a sense of their culture.

- Read reviews of the company on Glassdoor to get insights from current and former employees.

2. Practice answering common interview questions

There are some common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Prepare answers to common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”.

- Practice your answers out loud so that you can deliver them confidently.

- Be prepared to give specific examples of your skills and experience.

3. Be prepared to ask questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the job and the company culture. Prepare a few questions to ask the interviewer, such as “What are the biggest challenges facing the company right now?” and “What is the company’s culture like?”.

- Prepare a few questions to ask the interviewer, such as “What are the biggest challenges facing the company right now?” and “What is the company’s culture like?”.

- Be prepared to answer questions about your own experience and qualifications.

- Be confident and enthusiastic during your interview.

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you respect the interviewer and the company. You should also bring copies of your resume and any other relevant materials.

- Dress professionally, even if the company has a casual dress code.

- Arrive on time for your interview.

- Bring copies of your resume and any other relevant materials.

Next Step:

Now that you’re armed with the knowledge of Record Press Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Record Press Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini