Feeling lost in a sea of interview questions? Landed that dream interview for Redrying Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Redrying Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

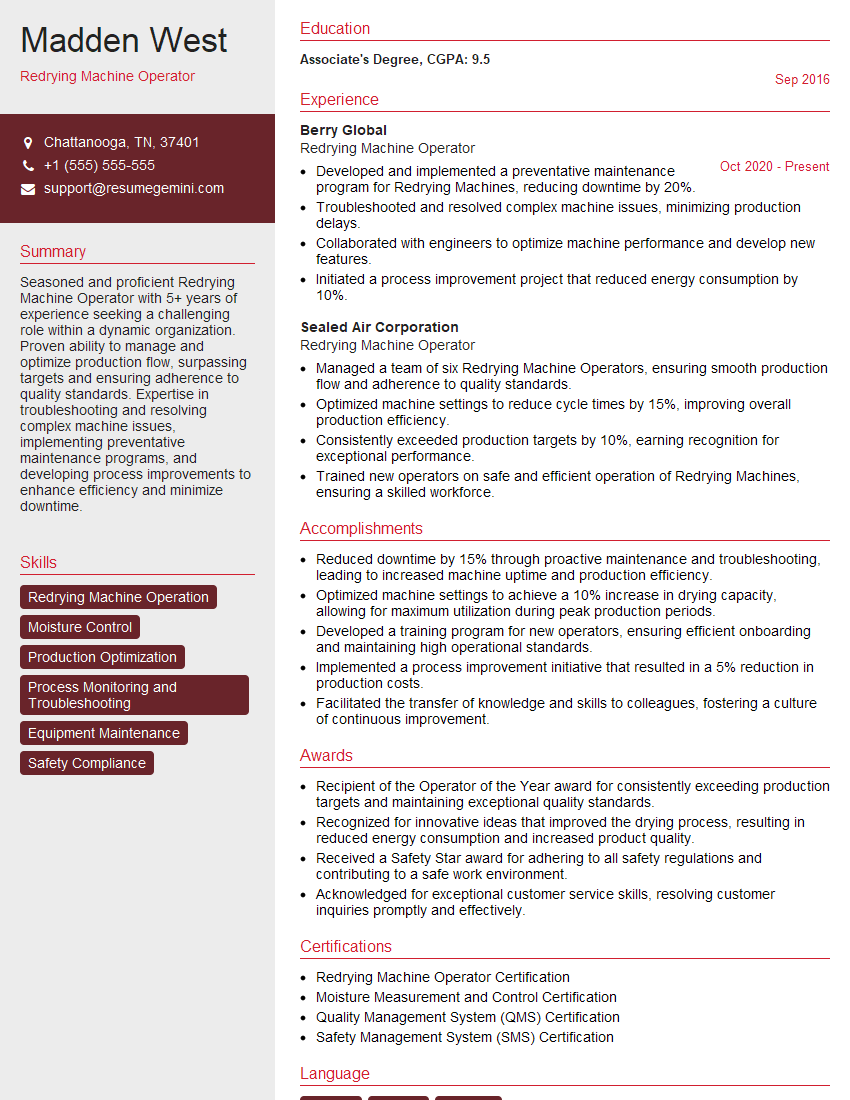

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Redrying Machine Operator

1. Explain the working principle of a redrying machine?

- Redrying machine is designed to remove excess moisture from materials by exposing them to hot air.

- The machine consists of a chamber where the material is placed on a conveyor belt and passed through a series of heated zones.

- Hot air is circulated through the chamber, absorbing moisture from the material.

- The dried material is then discharged from the machine.

2. Describe the different types of redrying machines available?

Conveyorized Redrying Machine

- Material is conveyed through a heated chamber on a conveyor belt.

- Suitable for drying large volumes of material.

Batch Redrying Machine

- Material is placed in a batch on trays or racks and loaded into a heated chamber.

- Used for drying smaller batches of material.

3. What are the key factors to consider when selecting a redrying machine?

- Type of material being dried

- Required moisture content

- Capacity and throughput requirements

- Energy efficiency

- Maintenance and operating costs

4. What are the safety precautions that must be followed when operating a redrying machine?

- Wear appropriate protective gear.

- Ensure the machine is properly grounded.

- Do not operate the machine unattended.

- Follow the manufacturer’s instructions for operation and maintenance.

- Be aware of the potential for fire and explosion.

5. How do you maintain a redrying machine?

- Regularly clean the machine to remove dust and debris.

- Inspect the heating elements and fans for damage.

- Lubricate moving parts as necessary.

- Calibrate the temperature and humidity controls.

6. What troubleshooting procedures would you follow if a redrying machine is not functioning properly?

- Check the power supply and fuses.

- Inspect the heating elements and fans.

- Check the temperature and humidity controls.

- Ensure the material is being properly loaded and unloaded.

7. Describe the quality control procedures that should be followed when operating a redrying machine.

- Monitor the temperature and humidity levels in the drying chamber.

- Regularly check the moisture content of the dried material.

- Inspect the dried material for any defects or contamination.

- Keep records of all quality control data.

8. How would you optimize the performance of a redrying machine?

- Use the appropriate settings for the material being dried.

- Ensure the machine is properly loaded and unloaded.

- Regularly clean and maintain the machine.

- Monitor the performance of the machine and make adjustments as necessary.

9. What are the safety concerns associated with the operation of a redrying machine?

- Fire and explosion hazards due to the presence of flammable solvents or materials.

- Electrical hazards due to the use of high-voltage equipment.

- Chemical hazards due to the use of solvents or other chemicals.

- Mechanical hazards due to moving parts.

10. How do you ensure the quality of the products produced by a redrying machine?

- Regularly calibrate the machine to ensure it is operating within specifications.

- Monitor the temperature and humidity levels in the drying chamber.

- Inspect the dried products for any defects or contamination.

- Keep records of all quality control data.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Redrying Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Redrying Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Redrying Machine Operators are responsible for operating and maintaining redrying machines in the production of textiles and fabrics. Their key responsibilities include:

1. Machine Operation

Loading redrying machines with wet or partially dried textile products.

- Setting and maintaining machine temperature, speed, and other operating parameters.

- Adjusting machine settings to control the drying process and product quality.

2. Quality Control

Monitoring the drying process to ensure that the products meet the specified quality standards.

- Inspecting products for defects, such as uneven drying or shrinkage.

- Making adjustments to the drying process based on quality checks.

3. Machine Maintenance

Performing routine maintenance tasks on redrying machines.

- Cleaning and inspecting the machine regularly.

- Identifying potential problems and taking appropriate actions to prevent breakdowns.

4. Safety Compliance

Adhering to all safety regulations and guidelines.

- Following proper operating procedures.

- Wearing appropriate safety gear.

Interview Tips

To prepare effectively for a Redrying Machine Operator interview, consider the following tips:

1. Research the Industry

Familiarize yourself with the textile industry, including the role of redrying machines in the production process.

- Read industry articles and publications.

- Visit industry websites and forums.

2. Highlight Relevant Experience

Emphasize any experience you have in operating or maintaining industrial machinery, especially in the textile industry.

- Use specific examples to demonstrate your skills.

- Quantify your accomplishments whenever possible.

3. Practice Common Interview Questions

Prepare for common interview questions asked to Redrying Machine Operators, such as:

- Tell us about your experience operating redrying machines.

- What steps do you take to ensure the quality of the products you dry?

- How do you handle potential problems with the machine during operation?

4. Dress Professionally and Arrive on Time

Make a positive impression by dressing appropriately and arriving on time for your interview.

- Choose attire that is clean and business-like.

- Plan your route and allow extra time for unexpected delays.

Next Step:

Now that you’re armed with the knowledge of Redrying Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Redrying Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini