Feeling lost in a sea of interview questions? Landed that dream interview for Reel and Rewinder Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Reel and Rewinder Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

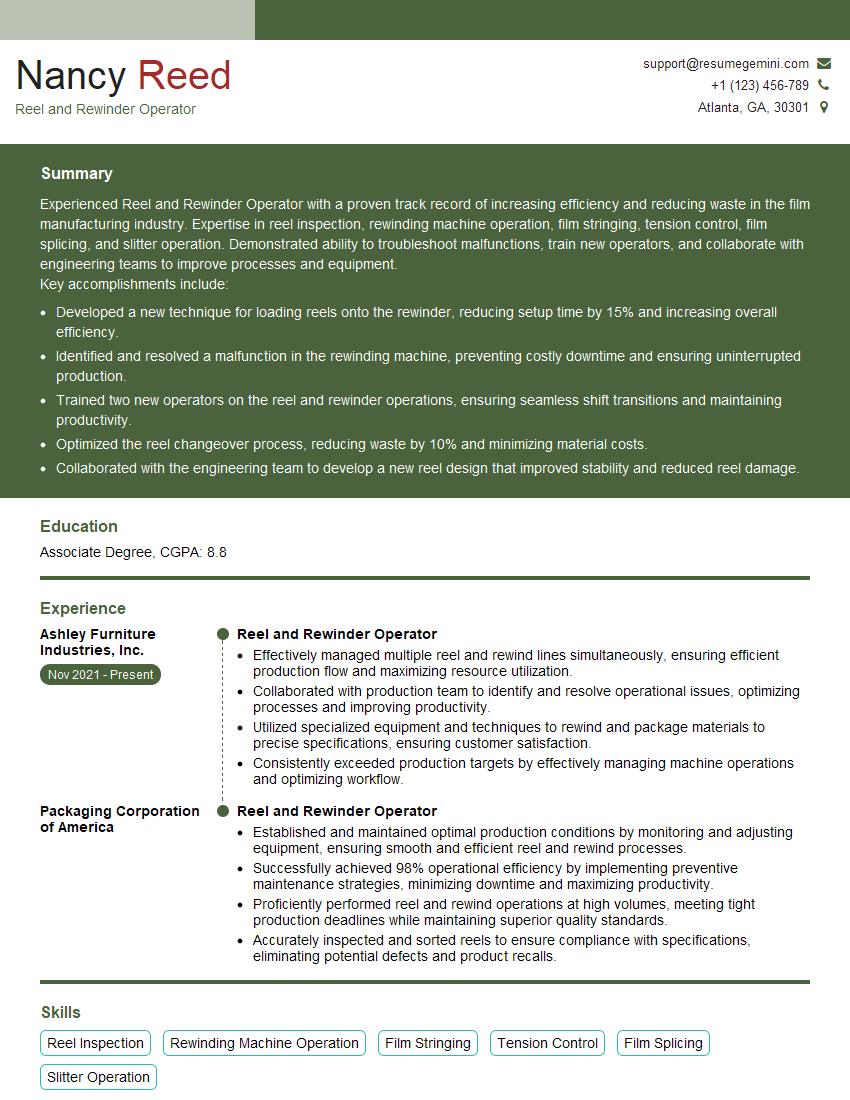

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reel and Rewinder Operator

1. What are the key responsibilities of a Reel and Rewinder Operator?

The key responsibilities of a Reel and Rewinder Operator include:

- Setting up and operating reel and rewinding machines

- Loading, unloading, and threading reels

- Inspecting materials for defects

- Making adjustments to machines to ensure proper operation

- Maintaining a clean and organized work area

2. What are the different types of reel and rewinding machines?

The different types of reel and rewinding machines include:

- Slitting machines

- Sheeting machines

- Laminating machines

- Coating machines

- Printing machines

3. What are the safety precautions that must be taken when operating reel and rewinding machines?

The safety precautions that must be taken when operating reel and rewinding machines include:

- Wearing appropriate safety gear, such as gloves, safety glasses, and earplugs

- Ensuring that the machine is properly grounded

- Keeping hands and feet away from moving parts

- Never operating the machine while under the influence of drugs or alcohol

- Following all manufacturer’s instructions

4. How do you troubleshoot common problems with reel and rewinding machines?

Some common problems with reel and rewinding machines include:

- Web breaks

- Incorrect tension

- Misaligned reels

- Damaged materials

To troubleshoot these problems, I would first check the machine for any obvious problems, such as loose connections or damaged parts. I would then consult the manufacturer’s instructions to determine the proper settings for the machine. If I am still unable to solve the problem, I would contact the manufacturer for assistance.

5. What are the maintenance procedures that need to be performed on reel and rewinding machines?

The maintenance procedures that need to be performed on reel and rewinding machines include:

- Regularly cleaning and lubricating the machine

- Checking the machine for any loose connections or damaged parts

- Calibrating the machine to ensure proper operation

- Following all manufacturer’s instructions

6. What are the different types of materials that can be processed on reel and rewinding machines?

The different types of materials that can be processed on reel and rewinding machines include:

- Paper

- Plastic

- Metal

- Textiles

- Film

7. What are the different applications for reel and rewinding machines?

The different applications for reel and rewinding machines include:

- Converting raw materials into finished products

- Packaging products

- Printing materials

- Laminating materials

- Coating materials

8. What are the advantages of using reel and rewinding machines?

The advantages of using reel and rewinding machines include:

- Increased efficiency

- Improved product quality

- Reduced costs

- Enhanced safety

9. What are the challenges of working as a Reel and Rewinder Operator?

The challenges of working as a Reel and Rewinder Operator include:

- Working in a fast-paced environment

- Operating heavy machinery

- Working with hazardous materials

- Meeting production targets

10. Why are you interested in working as a Reel and Rewinder Operator?

I am interested in working as a Reel and Rewinder Operator because I am a highly motivated and results-oriented individual with a strong work ethic. I am also a team player with excellent communication and interpersonal skills. I am confident that I have the skills and experience necessary to be successful in this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reel and Rewinder Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reel and Rewinder Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Reel and Rewinder Operators play a crucial role in manufacturing processes, specifically in the handling and manipulation of materials in the form of reels and spools. Their primary responsibilities include:

1. Material Handling

Operate and maintain reeling and rewinding equipment to transfer materials, such as paper, film, fabric, or metal, from one reel or spool to another.

- Prepare and load reels onto the equipment.

- Monitor the winding and unwinding process to ensure proper tension and alignment.

2. Quality Control

Inspect materials for defects, such as tears, wrinkles, or breaks, during the reeling and rewinding process.

- Identify and remove any damaged or defective materials.

- Maintain quality standards as per specifications.

3. Equipment Maintenance

Clean, lubricate, and perform routine maintenance on reeling and rewinding equipment.

- Identify and troubleshoot mechanical issues.

- Replace worn or damaged parts.

4. Safety and Compliance

Adhere to safety regulations and guidelines while operating equipment and handling materials.

- Wear appropriate personal protective equipment (PPE).

- Follow established safety procedures.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some helpful tips to help you ace your Reel and Rewinder Operator interview:

1. Research the Company and Position

Demonstrate your interest in the company and the specific role by researching their website, industry news, and any available information about the position.

- Identify the company’s values, goals, and industry position.

- Understand the specific responsibilities and requirements of the Reel and Rewinder Operator role.

2. Highlight Relevant Experience and Skills

Tailor your resume and interview responses to emphasize your relevant experience and skills. Quantify your accomplishments whenever possible.

- Describe your experience in operating reeling and rewinding equipment.

- Highlight your proficiency in quality control procedures.

- Provide examples of your ability to troubleshoot and maintain equipment.

3. Emphasize Safety and Compliance

Safety is paramount in manufacturing environments. Emphasize your commitment to following safety protocols and maintaining a safe work environment.

- Explain your understanding of industry safety regulations and best practices.

- Describe your experience in using personal protective equipment (PPE) and adhering to safety guidelines.

4. Practice Common Interview Questions

Prepare for common interview questions by practicing your responses. This will help you feel more confident and articulate during the interview.

- Example: Tell me about your experience with reeling and rewinding equipment.

- Example: How do you ensure the quality of materials during the process?

- Example: Describe a situation where you had to troubleshoot and repair equipment.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the position. It also gives you an opportunity to clarify any uncertainties.

- Example: Can you describe the team structure and reporting relationships for this role?

- Example: What are the company’s expectations for safety performance?

- Example: Are there any opportunities for professional development within the company?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Reel and Rewinder Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Reel and Rewinder Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.