Are you gearing up for a career in Reel Assembler? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Reel Assembler and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

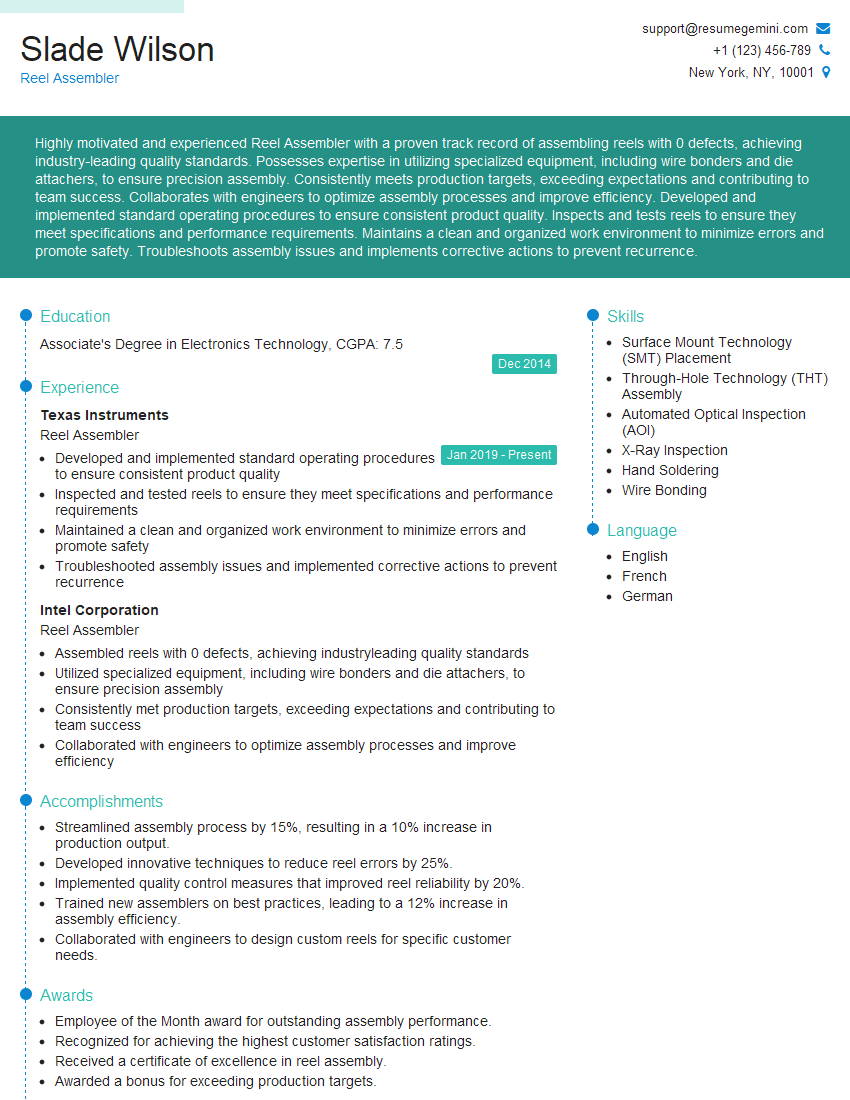

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reel Assembler

1. How do you maintain the uniformity of the reel’s winding tension?

As a Reel Assembler, maintaining consistent tension is crucial for ensuring the quality of the reels. I employ several techniques to achieve uniformity:

- Regularly calibrate and maintain the winding machine to ensure accurate tension settings.

- Use high-quality materials and components to minimize variations in tension during the winding process.

- Monitor the tension throughout the winding cycle to identify and adjust any deviations promptly.

- Establish standardized operating procedures and train operators to follow them precisely.

2. Describe the different types of reel materials and their respective advantages and disadvantages?

Metal Reels

- Advantages: Durable, resistant to wear and tear, suitable for heavy-duty applications.

- Disadvantages: Can be expensive, prone to corrosion if not properly maintained.

Plastic Reels

- Advantages: Lightweight, cost-effective, resistant to chemicals and moisture.

- Disadvantages: Less durable than metal reels, can be susceptible to deformation under high tension.

Composite Reels

- Advantages: Combine the strengths of both metal and plastic, offering durability and resistance to chemicals.

- Disadvantages: Can be more expensive than standard reels, may have limited availability.

3. What are the common defects encountered during reel assembly, and how do you prevent or rectify them?

Potential defects include:

- Uneven winding: Caused by improper tension, material defects, or machine malfunctions; can be prevented by regular machine maintenance and operator training.

- Loose or frayed edges: Can result from improper cutting or handling; can be prevented by using sharp cutting tools and proper handling techniques.

- Winding overlap: Occurs when the tape or wire overlaps during winding; can be prevented by maintaining proper tension and ensuring the alignment of the winding head.

- Tangled or knotted material: Can be caused by improper handling; can be prevented by careful material handling and ensuring smooth material flow.

4. Describe the safety protocols you observe while operating reel assembly equipment?

- Wear appropriate personal protective equipment, including gloves, safety glasses, and earplugs.

- Maintain a clean and organized work area to prevent tripping hazards.

- Follow established lockout/tagout procedures before performing maintenance or repairs.

- Be aware of the potential for pinch points and take precautions to avoid injuries.

- Report any safety concerns or potential hazards to supervisors immediately.

5. Explain the importance of reel balancing and how it affects the overall performance of the reel?

- Balanced reels reduce vibration and noise during operation.

- Improved balance extends the lifespan of the reel and its components.

- Balanced reels provide smoother unwinding and winding, reducing the risk of material tangling or breakage.

- Proper balancing enhances the overall efficiency and reliability of the reeling system.

6. Describe the maintenance procedures you follow to keep the reel assembly equipment in optimal condition?

- Regular cleaning and lubrication of all moving parts.

- Inspection and replacement of worn or damaged components.

- Calibration and testing of equipment to ensure accuracy and functionality.

- Documentation of all maintenance activities for tracking and auditing purposes.

- Adherence to manufacturer’s recommended maintenance schedules.

7. Explain the different methods used for inspecting reels after assembly?

- Visual inspection: Examination of reels for any visible defects or irregularities.

- Dimensional inspection: Measurement of reel dimensions to ensure compliance with specifications.

- Tension testing: Assessment of reel tension to ensure it meets required standards.

- Performance testing: Testing of reels in actual operating conditions to evaluate their functionality.

8. Describe the quality control measures implemented to ensure the production of high-quality reels?

- Establishment of clear quality standards and specifications.

- Regular inspection and testing of materials and components.

- Monitoring and control of production processes.

- Implementation of quality control checkpoints throughout the assembly line.

- Continuous improvement efforts based on data analysis and customer feedback.

9. Discuss the importance of teamwork in a reel assembly environment?

- Teamwork ensures smooth coordination and communication between team members.

- Collaboration allows for the sharing of knowledge and skills, leading to improved productivity.

- Teamwork fosters a sense of accountability and responsibility among members.

- Effective teamwork reduces errors and promotes a positive work environment.

10. How do you stay updated with the latest industry trends and advancements in reel assembly technology?

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Consulting with manufacturers and suppliers.

- Participating in online forums and discussions.

- Networking with peers and experts in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reel Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reel Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Reel Assembler, you will be responsible for overseeing and carrying out the assembly and inspection of reels used in various industrial applications. Your key responsibilities will include:

1. Reel Assembly

Assembling reels according to established specifications and quality standards, ensuring proper alignment and fit of components.

- Inspecting incoming materials and components for quality and accuracy.

- Selecting and utilizing appropriate tools and equipment for assembly.

- Following assembly procedures and blueprints to ensure adherence to design specifications.

- Testing assembled reels to verify functionality and meet performance requirements.

2. Quality Control

Conducting thorough inspections of assembled reels to identify and address any defects or non-conformances.

- Verifying dimensions, tolerances, and surface finishes using measuring instruments.

- Identifying and correcting assembly errors to maintain high quality standards.

- Documenting inspection results and reporting any non-conformances to the appropriate departments.

3. Maintenance and Troubleshooting

Performing routine maintenance and repairs on assembly equipment and tools to ensure optimal performance.

- Cleaning and lubricating equipment to prevent malfunctions and extend its lifespan.

- Troubleshooting assembly issues and implementing corrective actions to minimize downtime.

- Maintaining an organized and clean work area to promote efficiency and safety.

4. Production and Efficiency

Maintaining high levels of productivity by optimizing assembly processes and reducing waste.

- Identifying and implementing process improvements to increase efficiency and reduce cycle times.

- Monitoring production rates and identifying areas for optimization.

- Working as part of a team to ensure smooth production flow and meet deadlines.

Interview Tips

Preparing thoroughly for your interview will increase your chances of making a strong impression and landing the job. Here are some tips to help you excel:

1. Research the Company and Position

Take the time to learn about the company’s history, mission, and values. Research the specific role and its responsibilities to demonstrate your understanding and interest.

- Visit the company’s website and social media pages.

- Read industry articles and news related to the company and the position.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful and concise responses. Practice answering out loud to build confidence and fluency.

- Review common interview questions such as “Tell me about yourself” and “Why are you interested in this position?”

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and highlight your skills and experience.

3. Be Enthusiastic and Professional

Show enthusiasm for the position and the company during the interview. Maintain a positive and professional demeanor throughout the process.

- Dress appropriately and arrive on time for your interview.

- Make eye contact, smile, and engage with the interviewers.

4. Ask Thoughtful Questions

Asking insightful questions at the end of the interview demonstrates your interest and engagement. Prepare a few questions that show you’re eager to learn more about the company and the role.

- Inquire about the company’s growth plans or industry trends.

- Ask about opportunities for professional development and advancement.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Reel Assembler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.