Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Reel Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

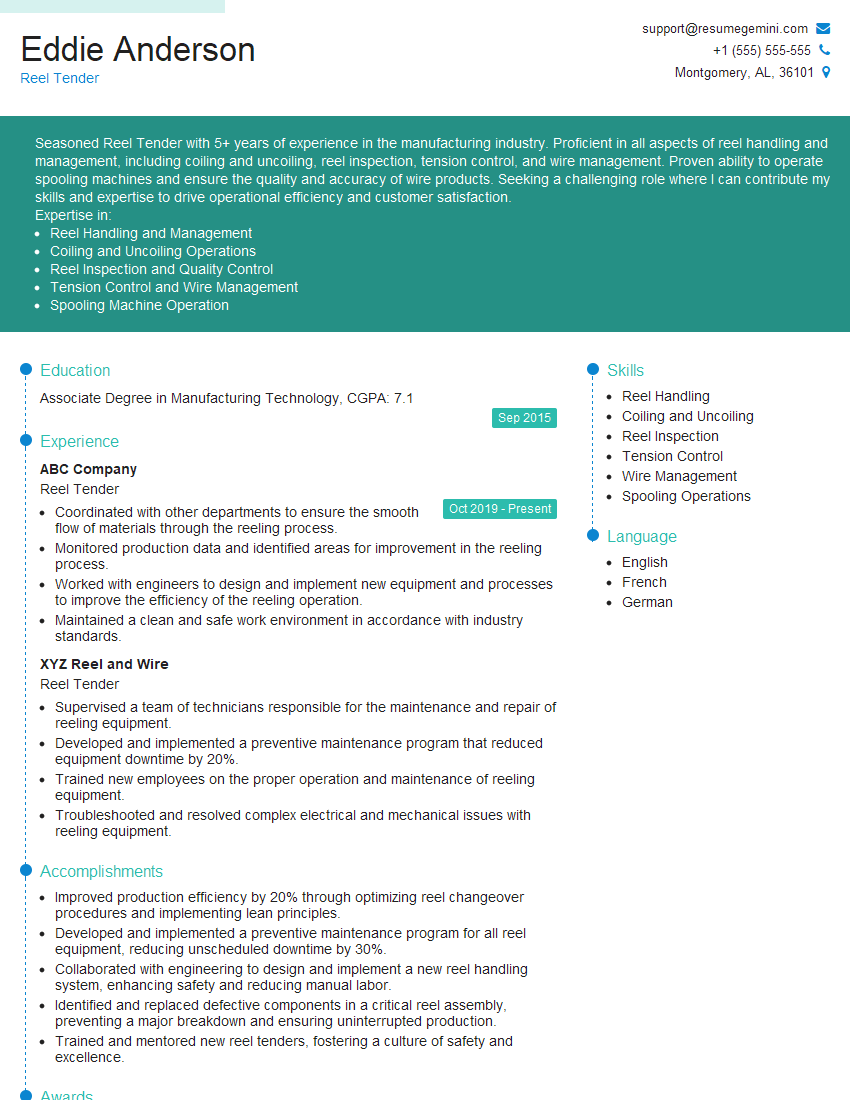

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reel Tender

1. What is your experience in operating and maintaining reel tension equipment?

With over 5 years of experience working extensively with reel tension equipment, I possess a thorough understanding of their operation and maintenance intricacies. I am proficient in handling diverse reel types, including single-turret, dual-turret, and capstan reels. Throughout my tenure, I have consistently ensured the smooth operation and precision winding of materials by effectively adjusting tension parameters and managing equipment settings.

2. Can you explain the importance of tension control in reel winding?

Tension control is of paramount importance in reel winding as it directly impacts the quality, efficiency, and safety of the process.

Benefits and Consequences of Tension Control:

- Optimal Winding Quality: Proper tension ensures uniform and consistent winding, preventing defects like telescoping, buckling, or material damage.

- Increased Production Efficiency: Controlled tension allows for higher winding speeds without compromising quality, maximizing productivity.

- Safety Enhancement: Uncontrolled tension can lead to reel or material breakage, posing safety hazards. Proper tension minimizes these risks.

- Equipment Protection: Excessive tension can strain reel components and damage equipment, so tension control extends their lifespan.

3. How do you troubleshoot and resolve common issues related to reel tension equipment?

Troubleshooting reel tension equipment involves a systematic approach to identify and rectify faults:

- Problem Identification: Identifying symptoms and understanding their potential causes.

- Inspection and Diagnosis: Visually inspecting equipment, checking settings, and analyzing data to pinpoint the issue.

- Solution Implementation: Implementing appropriate solutions, such as adjusting tension parameters, replacing worn components, or reconfiguring settings.

- Testing and Verification: Running test runs to confirm the effectiveness of implemented solutions and ensure optimal equipment performance.

4. What safety precautions should be observed when working with reel tension equipment?

To ensure safety when working with reel tension equipment, adhering to the following precautions is imperative:

- Proper Training and Authorization: Only trained and authorized personnel should operate the equipment.

- Personal Protective Equipment (PPE): Wearing appropriate PPE, including safety glasses, gloves, and hearing protection, is essential.

- Guarding and Barriers: Ensuring proper guarding and barriers around the equipment to prevent accidental contact with moving parts.

- Regular Maintenance and Inspections: Conducting regular maintenance checks and inspections to identify potential hazards and ensure equipment integrity.

- Emergency Stop Procedures: Understanding and practicing emergency stop procedures to respond swiftly to unexpected situations.

5. How do you maintain detailed records and documentation of reel tension equipment operations?

Maintaining accurate and detailed records and documentation is crucial for effective reel tension equipment management:

- Logbook Entries: Maintaining a logbook to record all inspections, maintenance activities, and any equipment-related incidents.

- Equipment History Files: Creating and maintaining equipment history files to track each reel tensioner’s maintenance and repair history.

- Calibration Records: Documenting calibration procedures and results to ensure ongoing accuracy and reliability.

- Performance Data Analysis: Analyzing performance data to identify trends, optimize tension settings, and improve overall efficiency.

6. What strategies do you employ to minimize material waste and improve yield during reel winding?

Minimizing material waste and improving yield during reel winding requires a combination of strategies:

- Optimizing Tension Control: Ensuring precise tension control prevents material breakage, telescoping, and other defects that lead to waste.

- Proper Reel Selection: Choosing the appropriate reel size and type based on material properties and winding requirements.

- Efficient Splicing Techniques: Utilizing appropriate splicing techniques and materials to minimize material loss during reel changes.

- Monitoring and Inspection: Continuously monitoring the winding process and inspecting materials to identify and rectify any issues promptly.

- Training and Education: Providing comprehensive training to operators on best practices for waste reduction and yield improvement.

7. How do you ensure the quality and consistency of wound reels?

Ensuring the quality and consistency of wound reels involves a multifaceted approach:

- Establishing Quality Standards: Defining clear and measurable quality standards for wound reels.

- Regular Inspections and Testing: Conducting thorough inspections and testing at various stages of the winding process to identify and correct any deviations.

- Process Control and Monitoring: Implementing statistical process control techniques to monitor and manage process variables, ensuring consistent output.

- Calibrated Equipment: Using calibrated and well-maintained equipment to guarantee accuracy and reliability in tension control.

- Operator Training and Certification: Training and certifying operators on proper winding techniques and quality control procedures.

8. How do you collaborate with other departments to ensure seamless reel winding operations?

Effective collaboration with other departments is essential for smooth reel winding operations:

- Production Planning: Coordinating with production planning to ensure timely availability of materials and resources.

- Quality Control: Working closely with quality control to establish and maintain quality standards, and promptly addressing any quality issues.

- Maintenance and Engineering: Collaborating with maintenance and engineering teams to ensure equipment reliability and resolve technical issues.

- Logistics and Shipping: Coordinating with logistics and shipping to ensure proper handling and transportation of wound reels.

9. Can you describe a situation where you successfully resolved a complex problem related to reel tension equipment?

In a previous role, I encountered a situation where the reel tension equipment experienced persistent fluctuations, resulting in inconsistent winding quality. I conducted a thorough investigation, analyzing equipment data and performing detailed inspections. I identified a faulty sensor as the root cause and promptly replaced it. Furthermore, I implemented a new calibration procedure to enhance sensor accuracy. These measures effectively resolved the issue, ensuring optimal reel tension and improved winding quality.

10. What is your understanding of the latest industry best practices and technological advancements in reel tension equipment?

I stay abreast of industry best practices and technological advancements by actively attending conferences, reading technical journals, and participating in online forums. Recent advancements include:

- Automated Tension Control Systems: These systems utilize advanced algorithms and sensors to precisely adjust tension based on material properties and winding conditions.

- Non-Contact Tension Measurement Techniques: These techniques employ lasers or other non-contact methods to measure tension accurately, minimizing material damage.

- Remote Monitoring and Diagnostics: Advanced monitoring and diagnostics capabilities allow for real-time data analysis and remote troubleshooting, enhancing equipment uptime.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reel Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reel Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Reel tenders play a crucial role in managing and maintaining the production line, ensuring the smooth operation of the equipment and producing high-quality products. Their key responsibilities include:

1. Monitoring and Controlling Equipment

Reel tenders are responsible for operating and monitoring production machinery, including reel stands, winders, and slitter-rewinders. They must ensure that equipment is functioning correctly, make necessary adjustments, and troubleshoot any issues that may arise.

- Conduct periodic inspections and maintenance checks.

- Monitor production speeds, tension, and other process parameters.

2. Material Handling and Quality Control

Reel tenders manage the flow of materials, from unwinding raw materials to rewinding finished products. They monitor material properties, ensure proper tension, and inspect products for defects. Their goal is to maintain product quality and minimize waste.

- Load and unload materials, such as reels, cores, and paper.

- Monitor and adjust material tension to prevent breaks or damage.

- Inspect finished products and tag defective items.

3. Machine Setup and Changeovers

Reel tenders are responsible for setting up and adjusting machinery for different production runs. They must follow detailed instructions, make necessary adjustments, and ensure that the equipment is operating optimally. Changeovers involve swapping out materials, changing tooling, and recalibrating the equipment.

- Follow production schedules and set up equipment accordingly.

- Change reels, cores, and other components efficiently.

- Calibrate and adjust machine settings for different materials and product specifications.

4. Safety and Maintenance

Reel tenders must prioritize safety in their daily tasks. They are responsible for maintaining a clean and organized work area, following all safety procedures, and communicating any potential hazards or concerns. They also assist in preventive maintenance and repairs to ensure equipment longevity.

- Follow all safety regulations and wear appropriate protective gear.

- Report any safety hazards or concerns to supervisors.

- Assist with equipment maintenance and repairs as needed.

Interview Preparation Tips

To prepare for an interview for a Reel Tender position, follow these tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry. Visit their website, read industry news, and understand the company’s place within the market. This knowledge will show the interviewer that you are genuinely interested in the role and the company.

2. Practice Self-Reflection

Take time to reflect on your past experiences and identify specific examples that highlight your skills and abilities. Consider how your previous responsibilities align with the job requirements. Preparing specific anecdotes will make your answers more impactful during the interview.

3. Prepare Questions for the Interviewer

Asking thoughtful questions to the interviewer demonstrates your engagement and curiosity. Prepare a few relevant questions that show your genuine interest in the company, the role, and the industry. This also gives you an opportunity to gather more information about the organization.

4. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive punctually for your interview. Punctuality shows respect for the interviewer’s time and conveys your eagerness to make a positive impression.

5. Introduce Yourself Effectively

The interviewer will likely ask you to introduce yourself. Prepare a concise and engaging introduction that highlights your relevant skills, experience, and why you are interested in the position. Keep your introduction brief and under one minute.

6. Highlight Your Skills and Experience

When answering questions, emphasize your skills and experience that are relevant to the Reel Tender role. Use the STAR method (Situation, Task, Action, Result) to structure your answers. This method provides a clear and concise way to describe your experiences and abilities.

7. Show Your Enthusiasm and Commitment

Throughout the interview, convey your enthusiasm for the position and the company. Express your interest in the role, explain how your skills and experience align with the requirements, and demonstrate your commitment to contributing to the organization’s success.

8. Ask Questions and Engage

Interviews are a two-way conversation. Ask thoughtful questions to the interviewer to show your interest and understanding of the role and the company. This also creates an opportunity to clarify any uncertainties and gather more information.

9. Practice Makes Perfect

Preparing for an interview is crucial. Practice answering common interview questions either on your own or with a friend or family member. The more prepared you are, the more confident you will appear and the better you will perform during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Reel Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!