Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Reeling Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

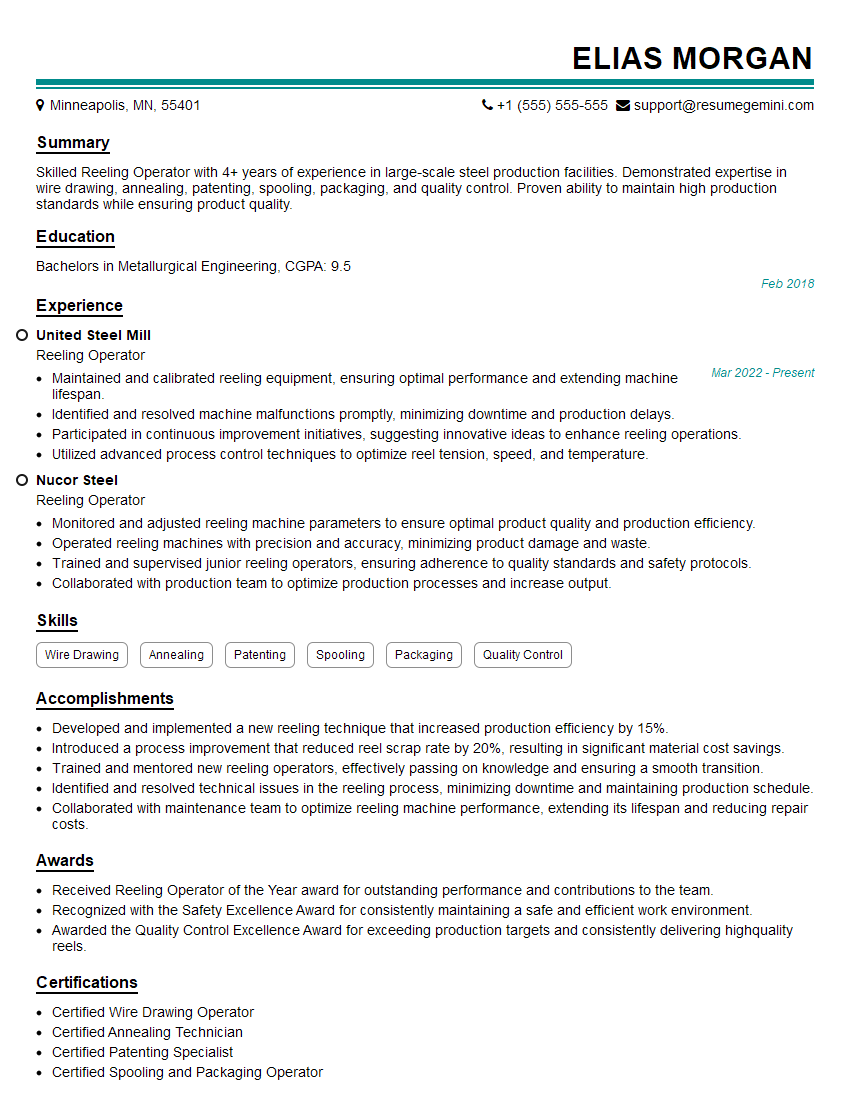

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reeling Operator

1. What are the key responsibilities of a Reeling Operator?

The primary responsibilities of a Reeling Operator include:

- Operating and maintaining reeling equipment to manage the flow of materials, ensuring proper winding and unwinding of products.

- Monitoring production lines to identify and resolve any issues promptly, ensuring smooth operation.

- Adjusting machine settings, such as tension and speed, to optimize productivity and maintain quality standards.

- Inspecting materials and finished products for defects, ensuring that they meet specifications and customer requirements.

2. Explain the different types of reeling machines and their applications?

Rotary Reeling Machines

- Used for winding and unwinding materials such as paper, film, and fabrics.

- Feature a rotating spindle that supports the material roll.

Slitting Reeling Machines

- Used for slitting and rewinding material into multiple rolls.

- Consist of a series of knives that cut the material into desired widths.

Tension Control Reeling Machines

- Used for maintaining consistent tension during winding and unwinding.

- Utilize sensors and control systems to adjust tension.

3. Describe the safety precautions that should be followed when operating reeling equipment?

To ensure safety when operating reeling equipment, it is essential to adhere to the following precautions:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Inspect the equipment before each use, checking for any damage or malfunctions.

- Ensure that the work area is clear of obstacles and potential hazards.

- Keep hands away from moving parts and nip points.

- Follow lockout/tagout procedures when performing maintenance or repairs.

4. What are some common problems that can occur during reeling operations and how do you troubleshoot them?

Some common problems that may arise during reeling operations include:

- Material wrinkles or creases: Adjust tension settings, check for any obstructions in the material path.

- Uneven winding: Inspect the alignment of the equipment and ensure the material is fed evenly.

- Material breakage: Check for sharp edges or tears in the material, adjust tension settings.

- Equipment overheating: Ensure proper lubrication and ventilation, check for any blockages or excessive friction.

5. How do you ensure the quality of finished products during reeling operations?

To ensure the quality of finished products during reeling operations, it is crucial to:

- Inspect the materials used for any defects or imperfections.

- Monitor the reeling process closely, making adjustments as needed to maintain proper tension and winding.

- Inspect the finished products for any damage or deviations from specifications.

- Maintain a clean and organized work area to minimize contamination.

6. How do you maintain and calibrate reeling equipment to ensure optimal performance?

Regular maintenance and calibration are essential to ensure optimal performance of reeling equipment:

- Daily maintenance: Clean and lubricate moving parts, check belt tension, inspect sensors.

- Regular calibration: Verify accuracy of tension and speed readings, calibrate sensors and controls.

- Preventive maintenance: Schedule periodic inspections and repairs to identify and address potential issues early.

7. How do you handle and manage waste and scrap materials generated during reeling operations?

Effective waste and scrap management is crucial for maintaining a clean and efficient work environment:

- Waste disposal: Properly dispose of waste materials in designated containers, follow environmental regulations.

- Scrap recycling: Identify and segregate recyclable materials, such as paper or plastic, for recycling.

- Waste minimization: Implement practices to reduce waste generation, such as optimizing material usage and reducing setup times.

8. What techniques do you use to minimize material waste and maximize yield during reeling operations?

To minimize waste and maximize yield, it is essential to:

- Optimize material usage: Plan and measure material requirements accurately to avoid overruns.

- Reduce setup times: Implement efficient setup procedures to minimize downtime and material waste.

- Utilize scrap recovery systems: Implement systems to collect and reuse scrap materials for other applications.

9. How do you stay updated with the latest advancements and best practices in the reeling industry?

To stay current with industry advancements and best practices:

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Participate in online forums and discussions.

10. Describe a challenging situation you faced as a Reeling Operator and how you overcame it?

In a previous role, I encountered a situation where the reeling machine developed a persistent tension issue that caused uneven winding. To resolve this, I:

- Inspected the machine thoroughly, checking for any loose components or misalignments.

- Adjusted the tension settings and recalibrated the tension sensor.

- Consulted with a senior technician to gain additional insights and solutions.

- Together, we implemented a new tension control strategy that effectively resolved the issue and improved product quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reeling Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reeling Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Reeling Operators are responsible for operating reeling machines, which wind and unwind wire, cable, and other materials. They work in a variety of industries, such as manufacturing, construction, and automotive. Some of the key job responsibilities include:

1. Operating Reeling Machines

Reeling Operators must be able to operate reeling machines safely and efficiently. This includes loading and unloading materials, setting up the machine, and monitoring its operation. They must also be able to identify and correct any problems that may arise.

- Loading and unloading materials

- Setting up the machine

- Monitoring the operation

- Identifying and correcting problems

2. Inspecting Materials

Reeling Operators must inspect materials before and after they are reeled. This includes checking for damage, defects, and contamination. They must also be able to identify and correct any problems that may arise during the inspection process.

- Identifying and correcting problems

- Checking for damage, defects, and contamination

- Ensuring that materials meet specifications

3. Maintaining Equipment

Reeling Operators are responsible for maintaining the reeling machines they operate. This includes cleaning, lubricating, and repairing the machines. They must also be able to identify and correct any problems that may arise during the maintenance process.

- Cleaning and lubricating the machines

- Repairing the machines

- Identifying and correcting problems

4. Following Safety Procedures

Reeling Operators must follow safety procedures when operating reeling machines. This includes wearing appropriate safety gear, following lockout/tagout procedures, and working in a safe manner. They must also be able to identify and correct any safety hazards that may arise during the reeling process.

- Wearing appropriate safety gear

- Following lockout/tagout procedures

- Working in a safe manner

- Identifying and correcting safety hazards

Interview Tips

Preparing for an interview can be a daunting task, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the Company and the Position

Take some time to learn about the company you are applying to and the position you are applying to. This will help you to understand the company’s culture and values, and it will also help you to answer questions about your qualifications and experience.

- Visit the company’s website

- Read the job description

- Talk to people who work at the company

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Use the STAR method to answer questions

- Be prepared to talk about your skills and experience

- Have questions prepared to ask the interviewer

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, as being late will make you look unprepared and unprofessional.

- Dress in business attire

- Arrive on time for your interview

- Be prepared to shake hands and make eye contact

4. Be Yourself and Be Confident

It is important to be yourself and be confident during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. And be confident in your abilities, as this will make the interviewer more confident in your ability to do the job.

- Be honest and authentic

- Be confident in your abilities

- Be enthusiastic about the opportunity

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Reeling Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!