Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Refiner Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

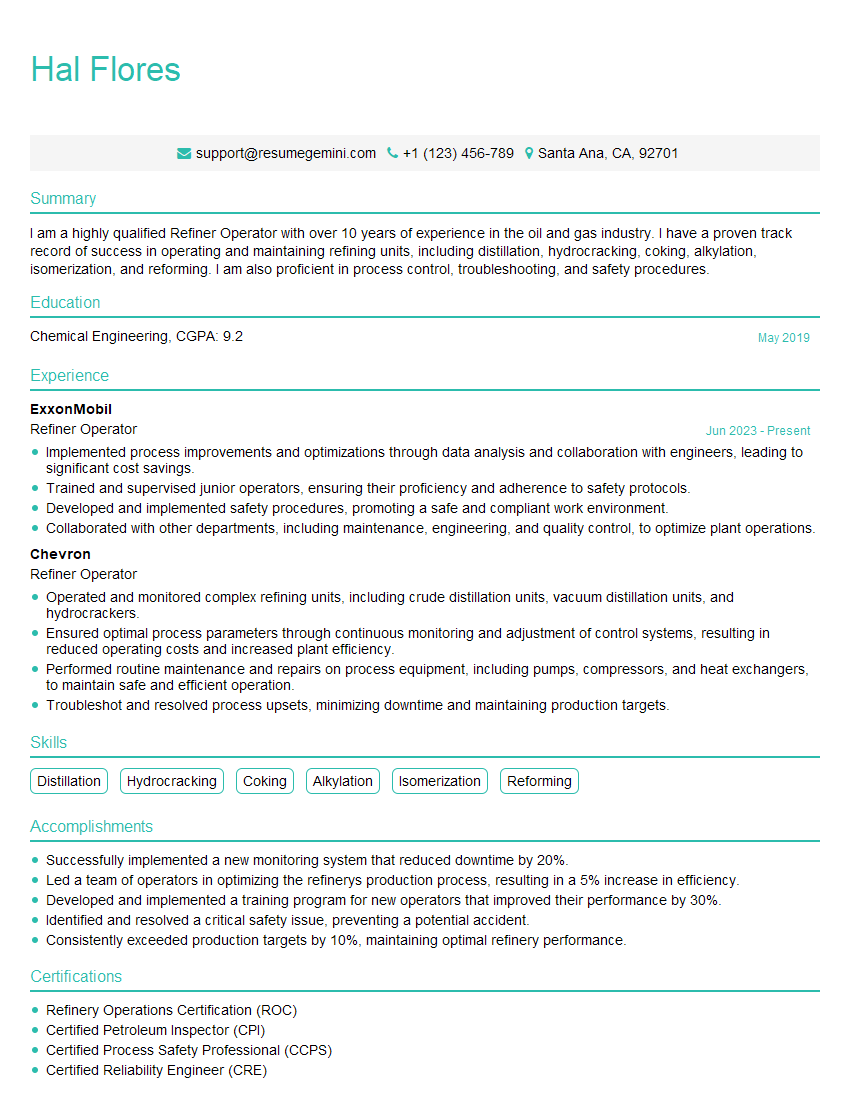

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Refiner Operator

1. What is the purpose of a vacuum distillation column in a refinery?

A vacuum distillation column is used to separate heavy petroleum fractions, such as gas oil and vacuum gas oil, under reduced pressure. This process helps to prevent thermal cracking and coking, which can occur when these fractions are distilled at higher temperatures and pressures.

2. Explain the role of a hydrotreater in a refinery.

- Hydrotreater removes impurities such as sulfur, nitrogen, and oxygen from petroleum fractions.

- It uses hydrogen gas in the presence of a catalyst to saturate and convert these impurities into hydrogen sulfide, ammonia, and water, respectively.

- The hydrotreated product has improved quality and stability, making it suitable for further processing or use as a finished product.

3. Describe the process of catalytic cracking.

- Catalytic cracking is a thermal conversion process that breaks down heavy petroleum fractions into lighter, more valuable products.

- It involves passing the feedstock over a catalyst at elevated temperatures, typically in the range of 450-550°C.

- The catalyst promotes the cracking reactions, resulting in the production of gasoline, jet fuel, and other products.

4. What are the key operating parameters that need to be monitored and controlled in a fluidized catalytic cracking (FCC) unit?

- Temperature: FCC units operate at high temperatures to promote cracking reactions.

- Pressure: The pressure inside the FCC unit affects the reaction rates and product yields.

- Catalyst circulation rate: The circulation rate of the catalyst is critical for maintaining the proper catalyst-to-feedstock ratio and ensuring efficient cracking.

- Feedstock composition: The composition of the feedstock can impact the cracking reactions and product yields.

5. Explain the purpose of a coker unit in a refinery.

- A coker unit is a thermal conversion process that converts heavy petroleum residues, such as vacuum bottoms, into lighter, more valuable products.

- It involves heating the feedstock to high temperatures in the absence of oxygen, causing the heavy hydrocarbons to break down into smaller molecules.

- The coker unit produces coke, which is a byproduct that can be used as a fuel or sold to other industries.

6. What are the different types of crude oil and how do their properties affect the refining process?

- Light crude oils: These are low in density and have a high API gravity, making them easier to refine.

- Heavy crude oils: These are high in density and have a low API gravity, making them more difficult to refine.

- Sweet crude oils: These have a low sulfur content, making them more desirable for refining.

- Sour crude oils: These have a high sulfur content, which can make refining more complex and expensive.

7. What are the safety hazards associated with working in a refinery and how can they be minimized?

- Fire and explosion: Refineries handle flammable materials, so there is always a risk of fire or explosion.

- Chemical exposure: Refineries use a variety of chemicals, which can be harmful if inhaled, ingested, or absorbed through the skin.

- Confined spaces: Refineries have many confined spaces, which can be hazardous if not properly ventilated.

- Rotating equipment: Refineries have a lot of rotating equipment, which can pose a risk of entanglement or amputation.

These hazards can be minimized by following proper safety procedures, wearing the appropriate personal protective equipment, and receiving regular safety training.

8. What are the environmental regulations that refineries must comply with?

- Air pollution regulations: Refineries must comply with regulations that limit the emissions of air pollutants, such as sulfur dioxide, nitrogen oxides, and particulate matter.

- Water pollution regulations: Refineries must comply with regulations that limit the discharge of pollutants into water bodies.

- Waste management regulations: Refineries must comply with regulations that govern the disposal of hazardous waste, such as spent catalysts and contaminated soil.

9. What is the role of a process operator in a refinery?

- Process operators are responsible for monitoring and controlling the operation of refinery units.

- They ensure that the units are operating safely and efficiently, and that the products meet the desired specifications.

- Process operators use a variety of tools and technologies to monitor and control the units, including distributed control systems (DCSs), programmable logic controllers (PLCs), and analytical instruments.

10. What are the career advancement opportunities for a refiner operator?

- Senior process operator

- Process engineer

- Production foreman

- Operations manager

- Refinery manager

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Refiner Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Refiner Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Refiner Operator is a highly trained professional who is responsible for the smooth and efficient operation of a refinery. They operate and monitor complex equipment, ensuring that the refining process runs smoothly and that products meet quality standards.

1. Operating and Monitoring Equipment

Refiner Operators are responsible for operating and monitoring a variety of equipment, including distillation towers, heat exchangers, and pumps. They must be able to identify and troubleshoot problems quickly and efficiently to ensure that the refining process continues to run smoothly.

- Operate and monitor distillation towers, heat exchangers, and pumps

- Identify and troubleshoot problems with equipment

- Make adjustments to equipment to maintain optimal operating conditions

2. Monitoring Process Parameters

Refiner Operators must be able to monitor process parameters, such as temperature, pressure, and flow rate, to ensure that the refining process is running smoothly. They must be able to identify and troubleshoot problems quickly and efficiently to prevent the process from shutting down.

- Monitor process parameters, such as temperature, pressure, and flow rate

- Identify and troubleshoot problems with process parameters

- Make adjustments to process parameters to maintain optimal operating conditions

3. Maintaining Safety and Environmental Standards

Refiner Operators are responsible for maintaining safety and environmental standards in the refinery. They must be able to identify and mitigate potential hazards, such as leaks, spills, and fires. They must also be aware of and comply with all applicable safety and environmental regulations.

- Identify and mitigate potential hazards

- Comply with all applicable safety and environmental regulations

- Maintain a clean and safe work environment

4. Communicating with Others

Refiner Operators must be able to communicate effectively with other members of the refinery team, including supervisors, engineers, and maintenance personnel. They must be able to provide clear and concise instructions and reports, and they must be able to work effectively as part of a team.

- Communicate effectively with other members of the refinery team

- Provide clear and concise instructions and reports

- Work effectively as part of a team

Interview Tips

Preparing for a job interview can be daunting, but it is important to remember that the interviewer is just as interested in getting to know you as you are in getting to know them. By following these tips, you can increase your chances of making a great impression and landing the job.

1. Research the Company and the Position

Before you go to the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals, and it will also help you prepare for the specific questions that you are likely to be asked.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work for the company

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and concisely.

- Prepare for common interview questions

- Practice answering questions in front of a mirror or with a friend

3. Be Yourself

It is important to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be confident, and let your personality shine through.

- Be yourself

- Don’t try to be someone you’re not

- Relax, be confident, and let your personality shine through

4. Ask Questions

Asking questions at the end of the interview shows that you are interested in the position and that you have taken the time to prepare. It also gives you an opportunity to learn more about the company and the position.

- Ask questions about the company

- Ask questions about the position

- Ask questions about the team

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Refiner Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!