Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Reflow Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Reflow Operator so you can tailor your answers to impress potential employers.

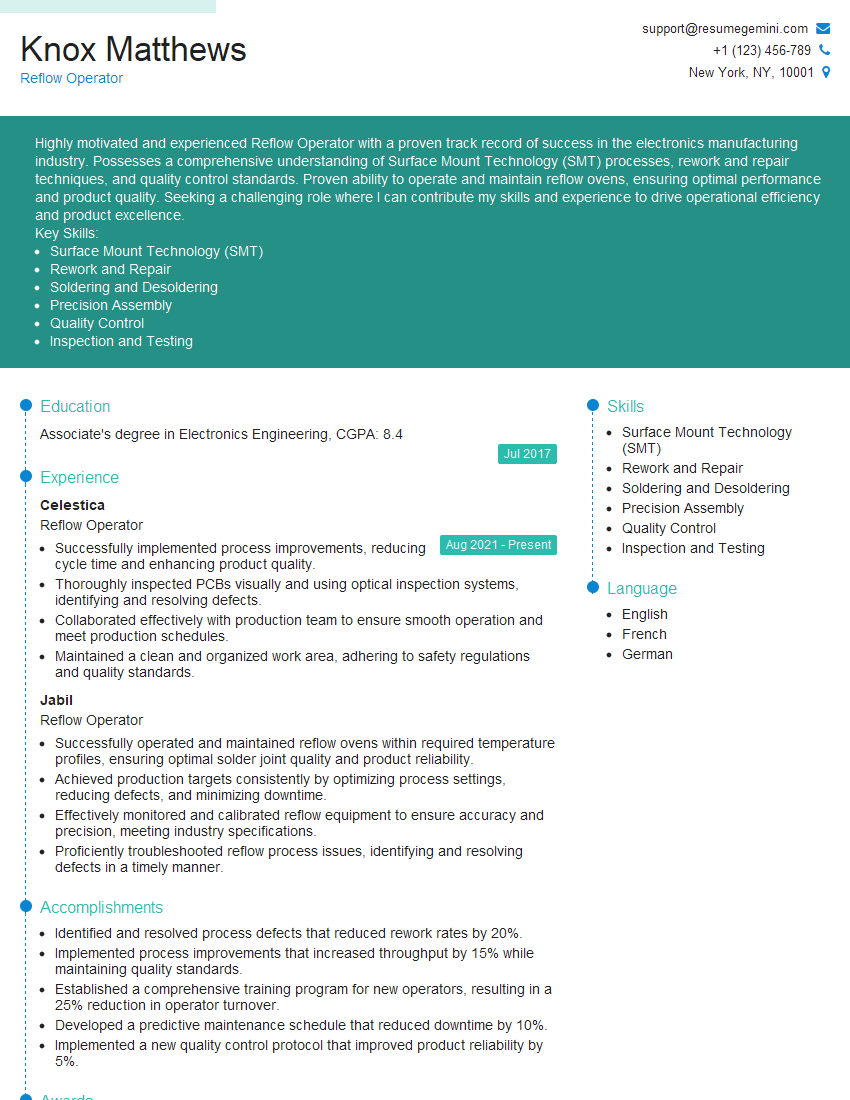

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reflow Operator

1. What is the purpose of a reflow oven?

A reflow oven is used to melt solder paste and solder components to a printed circuit board (PCB). The oven heats the PCB to a temperature that melts the solder paste, and then cools it to a temperature that solidifies the solder.

2. What are the different types of reflow ovens?

There are two main types of reflow ovens: convection ovens and infrared ovens.

Convection ovens

- Use hot air to heat the PCB.

- Are less expensive than infrared ovens.

- Take longer to heat the PCB.

Infrared ovens

- Use infrared radiation to heat the PCB.

- Are more expensive than convection ovens.

- Heat the PCB more quickly.

3. What are the key parameters of a reflow oven?

- Temperature

- Time

- Conveyor speed

- Atmosphere

4. How do you set up a reflow oven?

- Set the temperature to the desired profile.

- Set the time to the desired profile.

- Set the conveyor speed to the desired rate.

- Set the atmosphere to the desired composition.

5. How do you operate a reflow oven?

- Load the PCB into the oven.

- Start the oven.

- Monitor the oven temperature and time.

- Unload the PCB from the oven.

6. What are the common problems that can occur during reflow?

- Solder bridges

- Solder balls

- Component tombstoning

- PCB warpage

7. How do you troubleshoot reflow problems?

- Check the oven temperature and time.

- Check the conveyor speed.

- Check the atmosphere.

- Inspect the PCB for defects.

8. What are the safety precautions that must be followed when operating a reflow oven?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat.

- Do not touch the hot oven surfaces.

- Do not place flammable materials near the oven.

- Do not operate the oven unattended.

9. What are the maintenance procedures that must be performed on a reflow oven?

- Clean the oven regularly.

- Calibrate the oven temperature and time.

- Inspect the oven for defects.

- Service the oven as needed.

10. What are the quality control procedures that must be followed when using a reflow oven?

- Inspect the PCBs for defects before and after reflow.

- Monitor the oven temperature and time.

- Keep records of the reflow process.

- Train operators on the proper use of the oven.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reflow Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reflow Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Reflow Operator is responsible for operating and monitoring reflow ovens, ensuring the proper soldering of electronic components onto printed circuit boards (PCBs). Their key responsibilities include:

1. Oven Operation and Monitoring

Operate reflow ovens to solder components onto PCBs according to established process parameters.

- Monitor oven temperature, conveyor speed, and other process variables.

- Adjust settings as needed to maintain optimal soldering conditions.

2. Quality Control

Inspect soldered PCBs for defects, such as solder bridges, shorts, and opens.

- Use optical inspection equipment and other tools to verify solder quality.

- Identify and report any non-conforming products.

3. Maintenance and Troubleshooting

Perform routine maintenance on reflow ovens, including cleaning, calibration, and minor repairs.

- Troubleshoot and resolve oven malfunctions.

- Maintain a clean and organized work area.

4. Process Improvement

Monitor and analyze process data to identify areas for improvement.

- Suggest and implement process changes to enhance efficiency and quality.

- Stay updated on industry best practices and technological advancements.

Interview Tips

To ace an interview for a Reflow Operator position, candidates should follow these tips:

1. Research the Company and Position

Gather information about the company’s products, processes, and culture. Review the job description thoroughly to understand the specific requirements and expectations.

- Highlight your relevant skills and experience that align with the job responsibilities.

- Demonstrate your knowledge of reflow soldering techniques and quality control standards.

2. Prepare for Technical Questions

Expect to answer questions about reflow oven operation, soldering processes, and troubleshooting. Be prepared to discuss:

- Different types of reflow ovens and their capabilities.

- Process parameters for various types of solder paste.

- Common soldering defects and how to identify and correct them.

3. Showcase Your Problem-Solving Abilities

Interviewers will assess your ability to analyze problems and find solutions. Share examples of when you successfully identified and resolved issues in a manufacturing setting.

- Use the STAR method (Situation, Task, Action, Result) to describe your experiences.

- Quantify your accomplishments with specific metrics or outcomes whenever possible.

4. Emphasize Safety and Quality

A Reflow Operator must be safety-conscious and quality-oriented. Highlight your commitment to following safety protocols and maintaining high standards.

- Discuss your understanding of the importance of wearing appropriate personal protective equipment.

- Explain how you ensure the quality of your work by conducting thorough inspections and adhering to established procedures.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Reflow Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!