Are you gearing up for a career in Refractory Grinder Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Refractory Grinder Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

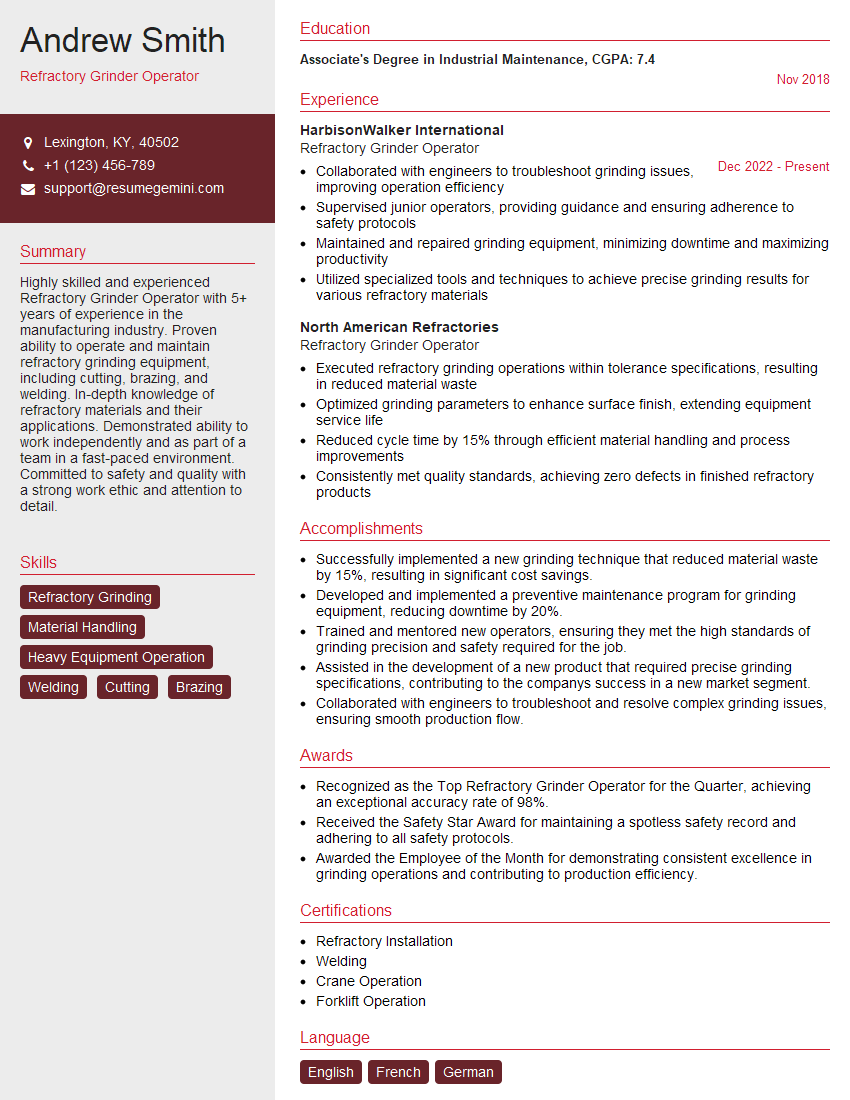

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Refractory Grinder Operator

1. What are the different types of refractory materials used in industrial applications?

- Acid-resistant refractories: These are used in applications where the refractory material is exposed to acidic conditions, such as in the production of sulfuric acid.

- Basic refractories: These are used in applications where the refractory material is exposed to basic conditions, such as in the production of steel.

- Neutral refractories: These are used in applications where the refractory material is not exposed to extreme acidic or basic conditions.

2. What are the different types of grinding wheels used for grinding refractory materials?

Diamond grinding wheels:

- These are the most durable and expensive type of grinding wheel, and they are used for grinding hard materials such as refractory bricks.

- Diamond grinding wheels are available in a variety of shapes and sizes, and they can be used for both wet and dry grinding.

CBN grinding wheels:

- These are made of cubic boron nitride, and they are almost as durable as diamond grinding wheels.

- CBN grinding wheels are used for grinding hard materials such as refractory metals.

Aluminum oxide grinding wheels:

- These are made of aluminum oxide, and they are used for grinding a variety of materials, including refractory materials.

- Aluminum oxide grinding wheels are available in a variety of shapes and sizes, and they can be used for both wet and dry grinding.

Silicon carbide grinding wheels:

- These are made of silicon carbide, and they are used for grinding a variety of materials, including refractory materials.

- Silicon carbide grinding wheels are available in a variety of shapes and sizes, and they can be used for both wet and dry grinding.

3. What are the safety precautions that must be taken when operating a refractory grinder?

- Wear appropriate safety gear, including eye protection, ear protection, and gloves.

- Ensure that the grinder is properly grounded to prevent electrical shock.

- Inspect the grinding wheel for any damage before using it.

- Never use a grinding wheel that is cracked or damaged.

- Keep the grinding area clean and free of debris.

- Do not grind materials that are too hard for the grinding wheel.

- Use the proper grinding technique to avoid kickback.

- Never leave the grinder unattended while it is running.

4. What are the different types of refractory products that can be ground using a refractory grinder?

- Refractory bricks

- Refractory shapes

- Refractory mortars

- Refractory castables

- Refractory plastics

5. What are the different types of grinding operations that can be performed using a refractory grinder?

- Surface grinding

- Cylindrical grinding

- Internal grinding

- Centerless grinding

6. What are the different factors that affect the grinding process?

- The type of refractory material being ground

- The type of grinding wheel being used

- The speed of the grinding wheel

- The feed rate of the workpiece

- The amount of coolant being used

7. What are the different types of coolants that can be used in a refractory grinding operation?

- Water

- Oil

- Synthetic coolants

8. What are the different types of dust collection systems that can be used in a refractory grinding operation?

- Bag filters

- Cartridge filters

- Cyclones

- Scrubbers

9. What are the different types of maintenance that must be performed on a refractory grinder?

- Daily maintenance: This includes cleaning the grinder, lubricating the moving parts, and checking the grinding wheel for wear.

- Weekly maintenance: This includes inspecting the electrical system, checking the coolant system, and changing the grinding wheel if necessary.

- Monthly maintenance: This includes inspecting the bearings, checking the belts, and performing any other necessary repairs.

10. What are the different types of problems that can occur with a refractory grinder?

- Grinding wheel wear

- Coolant leaks

- Electrical problems

- Mechanical problems

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Refractory Grinder Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Refractory Grinder Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Refractory Grinder Operators are responsible for the operation and maintenance of refractory grinding equipment. They ensure that the equipment is operating safely and efficiently, and that the refractory materials are ground to the correct specifications.

1. Operate refractory grinding equipment

Refractory Grinder Operators are responsible for the safe and efficient operation of refractory grinding equipment. This includes:

- Starting and stopping the equipment

- Monitoring the equipment’s operation

- Adjusting the equipment’s settings

- Troubleshooting and repairing the equipment

2. Maintain refractory grinding equipment

Refractory Grinder Operators are also responsible for the maintenance of refractory grinding equipment. This includes:

- Cleaning and lubricating the equipment

- Inspecting the equipment for wear and tear

- Replacing worn or damaged parts

- Calibrating the equipment

3. Ensure that the refractory materials are ground to the correct specifications

Refractory Grinder Operators are responsible for ensuring that the refractory materials are ground to the correct specifications. This includes:

- Measuring the size of the ground materials

- Adjusting the equipment’s settings to achieve the correct size

- Testing the ground materials to ensure that they meet the required specifications

4. Other duties

Refractory Grinder Operators may also be responsible for:

- Storing and handling refractory materials

- Training new employees

- Working with other members of the production team

Interview Tips

To prepare for an interview for a Refractory Grinder Operator position, you should:

1. Research the company and the position

Take some time to learn about the company and the specific position you are applying for. This will help you to understand the company’s culture and the requirements of the job.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

3. Be prepared to talk about your experience

The interviewer will likely want to know about your experience as a Refractory Grinder Operator. Be prepared to discuss your skills and knowledge, and to provide examples of your work.

4. Be prepared to ask questions

At the end of the interview, the interviewer will likely give you an opportunity to ask questions. This is a good time to ask about the company, the position, and the hiring process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Refractory Grinder Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!