Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Refractory Manager position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

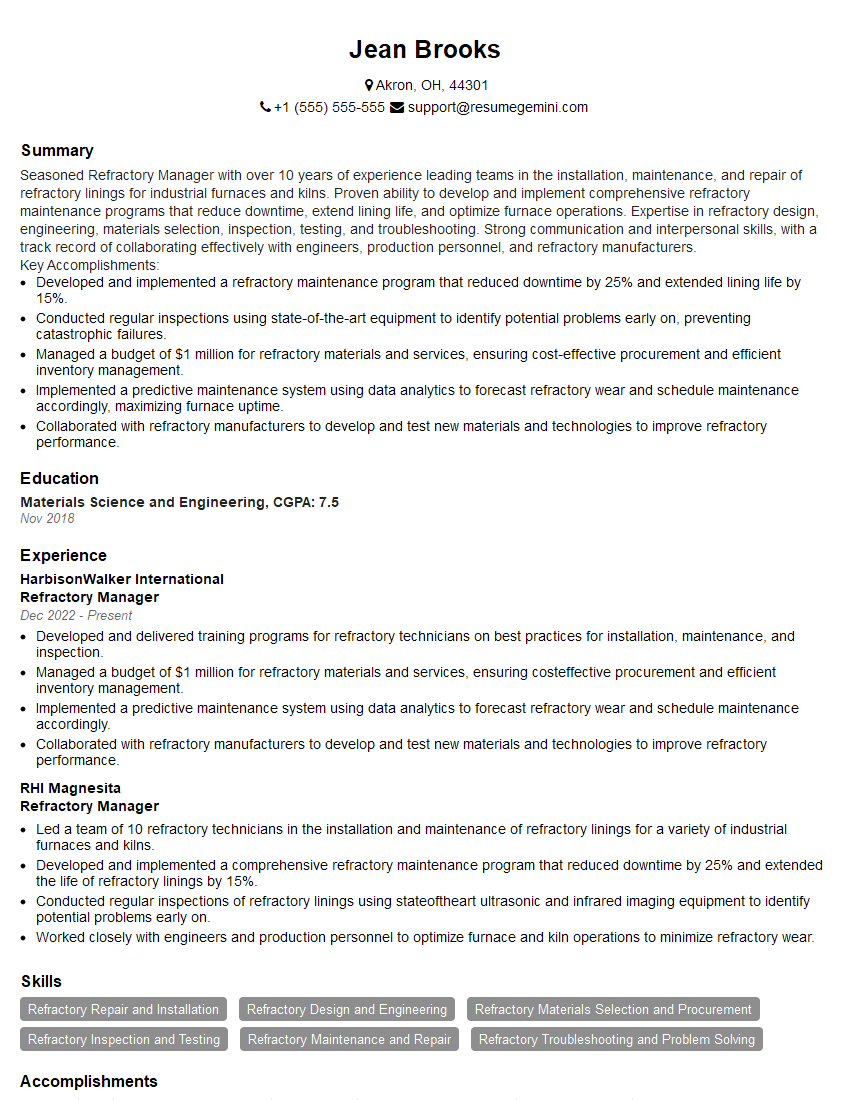

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Refractory Manager

1. What are the key physical and chemical properties of refractories?

- High melting point: Refractories must have a melting point that is higher than the operating temperature of the process in which they will be used. This is to ensure that they do not melt or deform at high temperatures.

- Low thermal conductivity: Refractories must have a low thermal conductivity to minimize heat loss through the lining.

- Chemical inertness: Refractories must be chemically inert to the process environment. This means that they must not react with the process materials or gases.

- High strength: Refractories must have high strength to withstand the loads and stresses imposed by the process.

- Good thermal shock resistance: Refractories must have good thermal shock resistance to withstand sudden changes in temperature without cracking or spalling.

2. What are the different types of refractories?

Acidic refractories

- Made from silica (SiO2)

- Resistant to acidic slags and gases

- Examples: silica bricks, fireclay bricks

Basic refractories

- Made from magnesia (MgO) or lime (CaO)

- Resistant to basic slags and gases

- Examples: magnesia bricks, dolomite bricks

Neutral refractories

- Made from chrome (Cr2O3) or alumina (Al2O3)

- Resistant to both acidic and basic slags and gases

- Examples: chrome-magnesia bricks, alumina bricks

Monolithic refractories

- Made from a mixture of refractory materials and a binder

- Can be cast or gunned into place

- Examples: castables, gunning mixes

3. What are the factors that affect the selection of refractories?

- Operating temperature

- Process environment

- Type of equipment

- Cost

- Availability

4. What are the common failure mechanisms of refractories?

- Thermal shock

- Chemical attack

- Mechanical wear

- Erosion

- Corrosion

5. How can refractory linings be inspected and maintained?

- Visual inspection

- Ultrasonic testing

- Infrared thermography

- Repairs: patching, gunning, casting

- Preventive maintenance: regular cleaning, monitoring

6. What are the latest developments in refractory technology?

- Advanced ceramic materials

- Nanotechnology

- Computer modeling

- Sustainable refractories

- Refractory coatings

7. What are the key challenges facing the refractory industry?

- Increasing demand for high-performance refractories

- Rising costs of raw materials

- Environmental regulations

- Skilled labor shortage

- Global competition

8. What are the quality control procedures for refractory products?

- Raw material testing

- In-process testing

- Final product testing

- Statistical process control

- Quality assurance system

9. What are the safety precautions that must be taken when working with refractories?

- Wear appropriate personal protective equipment (PPE)

- Handle refractories carefully to avoid dust inhalation

- Store refractories in a dry and well-ventilated area

- Dispose of refractories properly

- Be aware of the potential hazards of refractory materials

10. What are the career opportunities for refractory professionals?

- Refractory manager

- Refractory engineer

- Refractory sales representative

- Refractory installer

- Refractory researcher

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Refractory Manager.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Refractory Manager‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Refractory Managers oversee the planning, installation, and maintenance of refractory materials in industrial applications. These materials are used in high-temperature environments, such as furnaces and kilns, and play a vital role in protecting equipment and ensuring efficient operations. Key job responsibilities of a Refractory Manager include:

1. Refractory Material Management

Sourcing and procuring refractory materials based on specific application requirements

Ensuring proper inventory management and storage of refractory materials

Collaborating with suppliers and manufacturers to stay updated on latest refractory technologies and best practices

2. Refractory Design and Installation

Developing and implementing refractory designs that meet operational and safety requirements

Supervising the installation and commissioning of refractory linings in furnaces, kilns, and other high-temperature equipment

Inspecting refractory installations to ensure compliance with specifications and industry standards

3. Refractory Maintenance and Monitoring

Establishing and implementing routine inspection and maintenance schedules for refractory linings

Conducting periodic thermal audits and condition assessments to monitor refractory performance

Performing repairs and replacements of refractory linings as needed to ensure optimal equipment uptime

4. Technical Support and Training

Providing technical guidance and support to plant operations personnel on refractory-related matters

Developing and conducting training programs for employees involved in refractory installation, maintenance, and inspection

Staying abreast of industry developments and best practices through continuing education and professional networking

Interview Tips

To ace an interview for a Refractory Manager position, it’s essential to prepare thoroughly and demonstrate your expertise in refractory materials and management. Here are some tips to help you succeed:

1. Research the Company and the Industry

Before the interview, take some time to research the company you’re applying to and the refractory industry as a whole. This will help you understand their business operations, market position, and the challenges and opportunities they face.

Example Outline:

Explain your understanding of the company’s refractory operations and how your skills and experience align with their requirements.

2. Highlight Your Technical Expertise

During the interview, emphasize your technical knowledge and practical experience in refractory materials and management. Showcase your understanding of refractory design, installation, maintenance, and monitoring techniques.

Example Outline:

Provide specific examples of refractory projects you’ve managed, including the challenges you faced and the solutions you implemented.

3. Demonstrate Your Problem-Solving Skills

Refractory Managers are often faced with complex technical challenges. In the interview, highlight your ability to analyze problems, develop solutions, and make informed decisions. Share examples of situations where you’ve successfully resolved refractory-related issues.

Example Outline:

Describe a specific instance where you identified a refractory issue, diagnosed the root cause, and implemented a successful corrective action plan.

4. Emphasize Your Communication and Leadership Skills

Effective communication and leadership are essential for Refractory Managers. Showcase your ability to effectively interact with plant operations personnel, suppliers, contractors, and senior management. Highlight your experience in managing teams and motivating others to achieve common goals.

Example Outline:

Explain how you foster a positive work environment and build strong relationships with stakeholders.

Share an example of a time when you successfully negotiated a contract with a refractory supplier or resolved a conflict between team members.

5. Prepare Questions to Ask the Interviewer

Preparing thoughtful questions to ask the interviewer demonstrates your engagement and interest in the position and the company. Ask questions about the company’s strategic plans, current challenges, and opportunities for professional growth.

Example Outline:

Inquire about the company’s investment in refractory research and development.

Ask about the company’s approach to sustainability and environmental compliance in refractory management.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Refractory Manager role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.