Are you gearing up for a career in Refractory Mixer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Refractory Mixer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

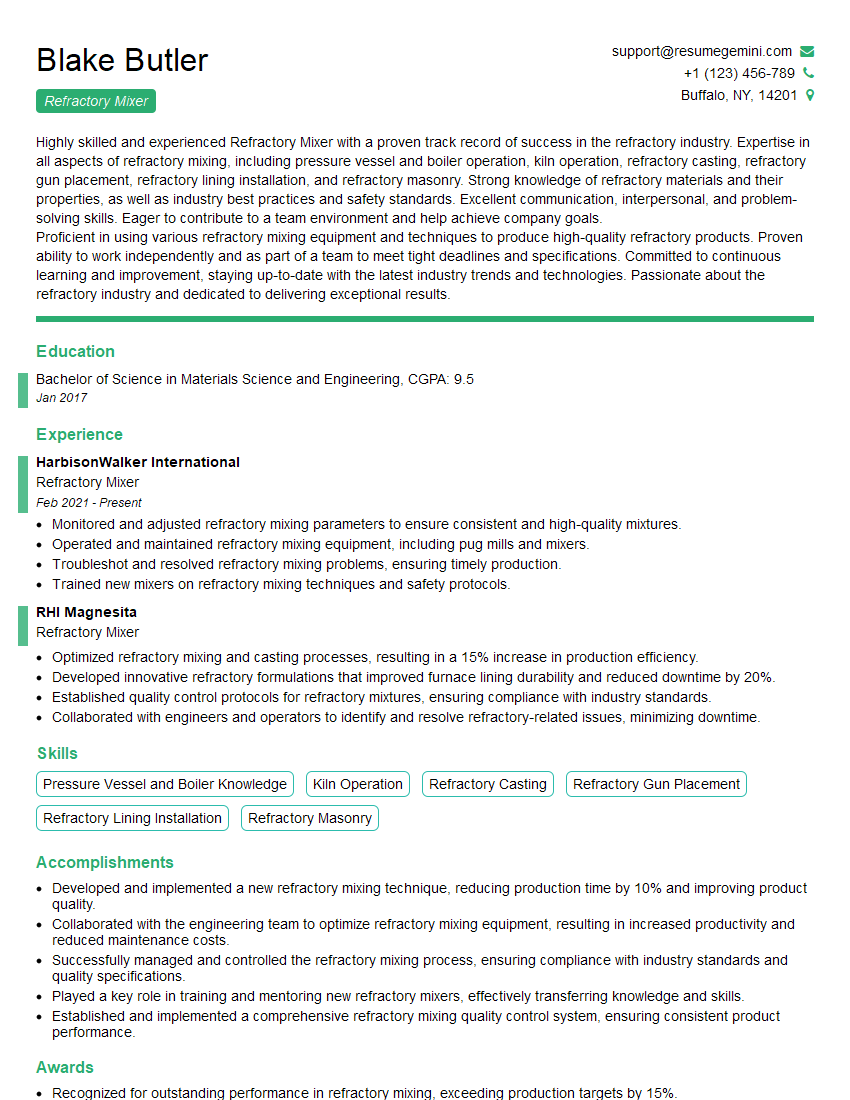

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Refractory Mixer

1. What is the function of a refractory mixer?

A refractory mixer is a piece of equipment used in the refractory industry to mix and blend different types of refractory materials. The purpose of using a refractory mixer is to create a homogenous mixture of raw materials, which can then be used to manufacture refractory products such as bricks, monoliths, and castables.

2. What are the different types of refractory mixers?

Batch mixers

- Used for small-scale mixing operations

- Materials are mixed in a batch process

Continuous mixers

- Used for large-scale mixing operations

- Materials are continuously fed into the mixer and mixed

3. What are the key factors to consider when selecting a refractory mixer?

- Capacity of the mixer

- Type of materials to be mixed

- Mixing time required

- Power consumption of the mixer

- Maintenance requirements of the mixer

4. What are the different types of refractory materials that can be mixed in a refractory mixer?

- Aggregates

- Binders

- Additives

5. What are the steps involved in operating a refractory mixer?

- Loading the mixer with materials

- Starting the mixer and mixing the materials

- Discharging the mixed materials

- Cleaning the mixer

6. What are the safety precautions that should be taken when operating a refractory mixer?

- Wear appropriate personal protective equipment

- Keep the work area clean and free of debris

- Do not overload the mixer

- Do not operate the mixer if it is damaged

- Follow all manufacturer’s instructions

7. What are the common problems that can occur when operating a refractory mixer?

- Material segregation

- Improper mixing

- Overheating of the materials

- Mechanical failure of the mixer

8. How can the problems that occur when operating a refractory mixer be solved?

- Material segregation: Use a mixer with a more effective mixing mechanism

- Improper mixing: Increase the mixing time or use a more powerful mixer

- Overheating of the materials: Use a mixer with a cooling system or reduce the mixing speed

- Mechanical failure of the mixer: Contact the manufacturer for repairs or maintenance

9. What are the benefits of using a refractory mixer?

- Improved mixing quality

- Reduced mixing time

- Increased production efficiency

- Lower manufacturing costs

10. What are the latest trends in the development of refractory mixers?

- Development of new mixing mechanisms

- Integration of advanced control systems

- Use of new materials

- Focus on sustainability

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Refractory Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Refractory Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Refractory Mixer plays a crucial role in the manufacturing process of refractory materials used in various industries. Their primary responsibilities include:

1. Mixing and Blending Refractory Materials

Refractory Mixers are responsible for preparing mixtures of refractory raw materials, including oxides, carbides, and nitrides, according to specified ratios and recipes.

- Calculate and weigh the appropriate quantities of materials

- Operate mixing equipment to blend ingredients thoroughly

2. Quality Control and Testing

Ensuring the quality of refractory mixtures is paramount. Refractory Mixers conduct various tests to verify the properties of the blended materials.

- Perform chemical and physical tests, such as particle size analysis and density measurements

- Monitor and adjust mixing parameters to meet specifications

3. Material Handling and Storage

Proper material handling and storage are essential for preventing contamination and maintaining the quality of refractory mixtures.

- Unload and store raw materials safely

- Maintain inventory and ensure proper rotation of stock

4. Equipment Maintenance and Calibration

Refractory Mixers are responsible for maintaining mixing equipment in optimal condition to ensure accurate and efficient operations.

- Clean and calibrate mixing equipment regularly

- Identify and troubleshoot any equipment issues

Interview Preparation Tips

Preparing thoroughly for a Refractory Mixer interview can significantly improve your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This knowledge will demonstrate your interest and enthusiasm for the role.

2. Review the Job Description

Carefully study the job description and identify the key responsibilities and requirements. Highlight your skills and experience that align with these expectations.

3. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses. Practice delivering your answers clearly and concisely, showcasing your knowledge and abilities.

4. Prepare Questions for the Interviewer

Asking well-informed questions at the end of the interview indicates your engagement and interest. Prepare questions that clarify the role, company culture, or industry prospects.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the occasion and punctuality demonstrates your respect for the interviewer’s time.

6. Be Confident and Enthusiastic

Project a positive attitude and convey your enthusiasm for the position. Confidence in your abilities and a genuine interest in the company will make a lasting impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Refractory Mixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!