Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Refractory Repairer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Refractory Repairer so you can tailor your answers to impress potential employers.

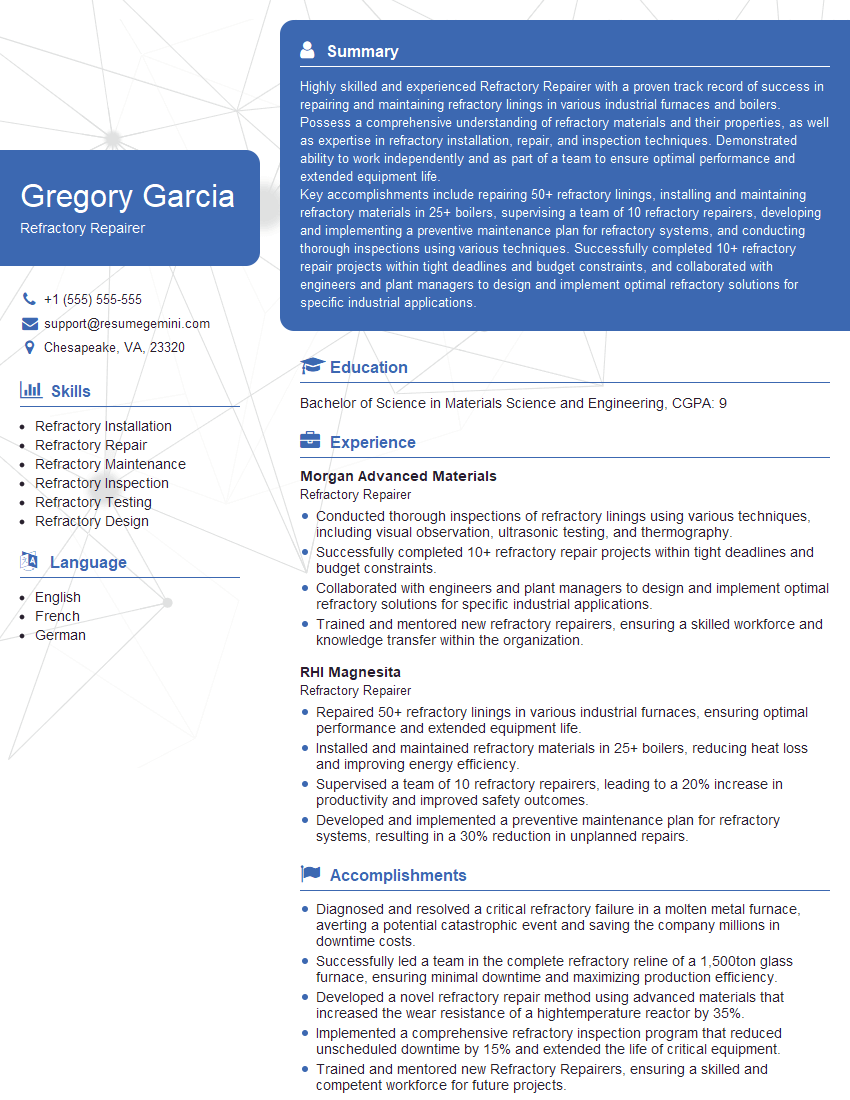

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Refractory Repairer

1. Explain the process of refractory brick installation.

The process of refractory brick installation involves several key steps:

- Surface preparation: The surface where the refractory bricks will be installed must be clean and level. Any existing refractories should be removed, and the surface should be inspected for any cracks or damage.

- Mortar selection: The appropriate mortar for the specific application should be selected. Different types of mortars have different properties, such as temperature resistance and chemical resistance.

- Brick preparation: The refractory bricks should be inspected for any defects, and they should be cut to the appropriate size if necessary.

- Brick installation: The bricks are laid in a mortar bed, and they are tapped into place with a hammer. The joints between the bricks should be filled with mortar, and the excess mortar should be removed.

- Curing: The refractory bricks need to be cured before they can be put into service. This involves heating the bricks gradually to the desired temperature.

2. How do you determine the type of refractory material to be used for a specific application?

Factors to consider when choosing a refractory material:

- Temperature: The refractory material must be able to withstand the temperatures that will be encountered in the application.

- Chemical environment: The refractory material must be resistant to the chemicals that will be present in the application.

- Physical requirements: The refractory material must have the appropriate physical properties, such as strength, abrasion resistance, and thermal conductivity.

- Cost: The cost of the refractory material must be considered.

Types of refractory materials:

- Fireclay

- High-alumina

- Silica

- Magnesia

- Chrome-magnesia

3. What are the common causes of refractory failure?

- Thermal shock

- Chemical attack

- Mechanical damage

- Material defects

- Improper installation

4. How do you maintain and repair refractory linings?

Refractory linings require regular maintenance and repair to ensure their longevity and performance:

- Inspections: Refractory linings should be inspected regularly for any signs of damage or wear.

- Repairs: Any damaged or worn areas should be repaired promptly using the appropriate materials and techniques.

- Preventive maintenance: Preventive maintenance measures, such as gunning or patching, can help to extend the life of the refractory lining.

5. What safety precautions should be taken when working with refractory materials?

- Wear appropriate protective clothing, including gloves, safety glasses, and a respirator.

- Handle refractory materials with care, as they can be sharp and abrasive.

- Do not work with refractory materials near open flames or sparks.

- Ensure that the work area is well-ventilated.

- Follow all safety procedures and guidelines.

6. What are the latest trends in refractory technology?

- The use of new materials, such as ceramics and composites

- The development of new techniques for manufacturing and installing refractory linings

- The use of computer modeling to optimize refractory design and performance

7. What is the difference between a hot face and a cold face refractory?

8. What are the properties of a good refractory material?

- High temperature resistance

- Low thermal conductivity

- Chemical resistance

- Strength and durability

- Cost-effectiveness

9. What are the challenges of working with refractory materials?

- Refractory materials can be difficult to handle and install.

- They are often exposed to harsh conditions, which can lead to premature failure.

- Refractory materials can be expensive.

10. What is your experience with refractory materials?

I have been working with refractory materials for the past 5 years. I have experience in all aspects of refractory repair, including installation, maintenance, and repair. I am also familiar with the latest trends in refractory technology.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Refractory Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Refractory Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Refractory Repairers are responsible for maintaining and repairing refractory linings in industrial furnaces, kilns, and other high-heat applications. They play a crucial role in ensuring the efficient and safe operation of these critical equipment.

1. Refractory Installation and Repair

Install, repair, and replace refractory linings in furnaces, kilns, and other high-temperature equipment.

- Determine the appropriate type and thickness of refractory materials for specific applications.

- Use specialized tools and techniques to install and repair refractory linings with precision.

2. Inspection and Maintenance

Inspect refractory linings for damage, wear, or cracks regularly.

- Conduct visual inspections and use specialized equipment to detect potential issues.

- Schedule and perform preventive maintenance to extend the lifespan of refractory linings.

3. Material Handling and Preparation

Handle and prepare refractory materials properly to ensure optimal performance.

- Unload and store refractory materials according to specifications.

- Mix and prepare refractory materials using appropriate techniques and equipment.

4. Safety and Environmental Compliance

Follow safety protocols and adhere to environmental regulations related to refractory repair work.

- Wear appropriate personal protective equipment (PPE) and follow safety guidelines.

- Comply with environmental regulations regarding hazardous materials and waste disposal.

Interview Tips

Preparing for a Refractory Repairer interview requires a thorough understanding of the job responsibilities and technical skills required for the role. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s business, products, and industry trends. This shows the interviewer that you are genuinely interested in the opportunity and have taken the time to learn about the company.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay up-to-date on the latest trends and technologies.

2. Highlight Your Technical Expertise

Emphasize your skills and experience in refractory installation, repair, and maintenance. Provide specific examples of projects you have worked on and the techniques you used to ensure successful outcomes.

- Describe a complex refractory repair you completed, outlining the challenges you faced and the solutions you implemented.

- Discuss your knowledge of different refractory materials and their applications.

3. Demonstrate Safety Consciousness

Highlight your commitment to safety in the workplace. Describe your experience with safety protocols, PPE usage, and emergency procedures.

- Emphasize your understanding of the hazards associated with refractory work and your adherence to safety guidelines.

- Provide examples of how you have promoted a safe work environment for yourself and others.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the role. Prepare questions that demonstrate your curiosity and knowledge of the industry.

- Inquire about the company’s future plans and growth prospects.

- Ask about the specific challenges and opportunities associated with the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Refractory Repairer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!