Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Refractory Specialist interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Refractory Specialist so you can tailor your answers to impress potential employers.

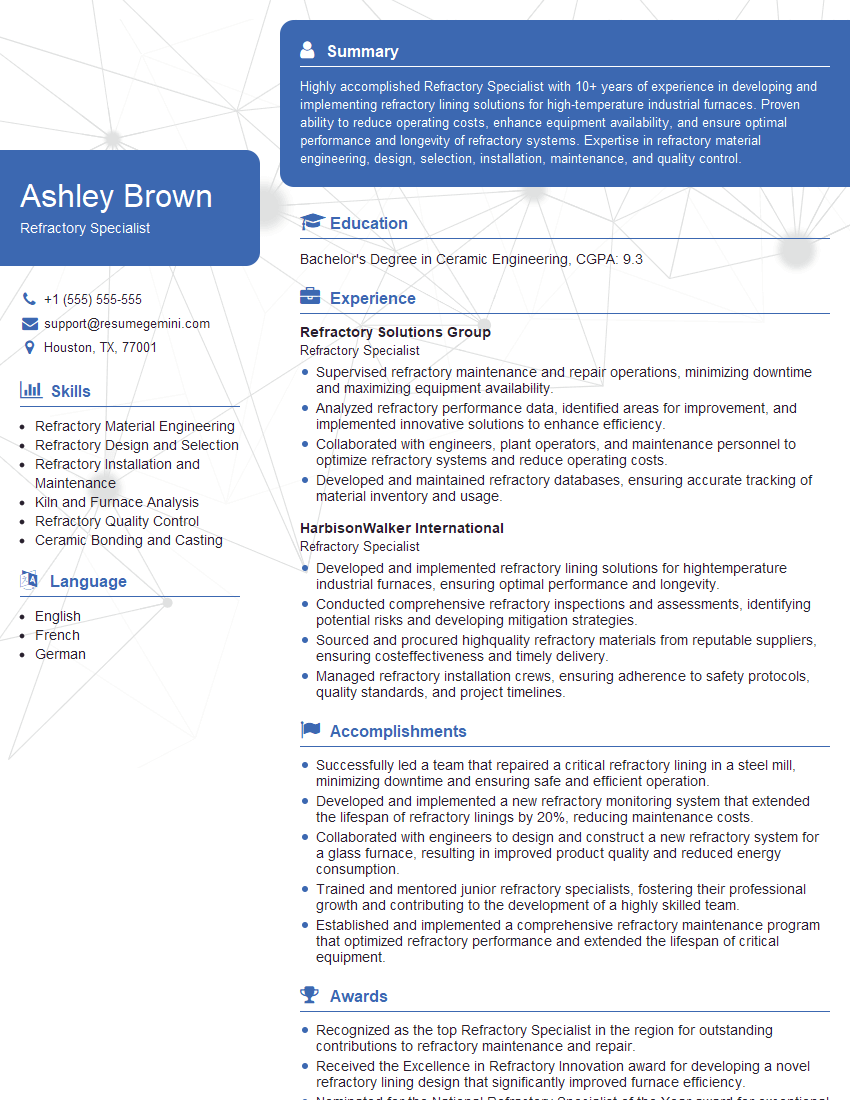

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Refractory Specialist

1. Describe the key properties of refractory materials and how they are tailored to specific applications?

Refractory materials are characterized by their exceptional resistance to high temperatures, corrosion, and wear. Their properties must be carefully tailored to meet the specific demands of their intended applications. For instance, in the steel industry, refractories withstand the intense heat and molten metal encountered during the steelmaking process.

2. Explain the different types of refractory materials and provide examples of their applications.

Acidic Refractories

- Composed of silica or alumina

- Used in glass furnaces and ceramic kilns

Basic Refractories

- Contain oxides of calcium, magnesium, or chromium

- Employed in steelmaking furnaces and cement kilns

Neutral Refractories

- Made of carbon or graphite

- Utilized in electric arc furnaces and induction furnaces

3. Discuss the testing methods employed to evaluate the properties of refractory materials.

- Refractoriness Under Load (RUL): Measures resistance to deformation at high temperatures

- Cold Crushing Strength (CCS): Determines compressive strength at room temperature

- Porosity and Apparent Density: Assesses the material’s physical structure

4. Describe the process of refractory installation and the factors that affect its performance.

Refractory installation involves careful planning and execution to ensure optimal performance and longevity. Factors that influence the installation process include:

- Selection of appropriate refractory materials

- Proper preparation of the substrate

- Correct installation techniques

- Curing and drying procedures

5. Explain how refractory materials are used in thermal insulation and protection.

Refractory materials play a crucial role in thermal insulation and protection. They are used in various applications such as:

- Industrial furnaces and boilers

- Kilns and ovens

- Exhaust systems

- Heat exchangers

6. Discuss the advantages and disadvantages of using monolithic refractories over shaped refractories.

Monolithic Refractories

Advantages:

- No joints or seams, reducing potential failure points

- Can be applied to complex shapes

Disadvantages:

- Lower mechanical strength compared to shaped refractories

Shaped Refractories

Advantages:

- High mechanical strength

- Precise dimensions and shapes

Disadvantages:

- Joints and seams can weaken the structure

7. Describe the role of refractory coatings and their benefits.

Refractory coatings are applied to refractory linings to enhance their performance and extend their lifespan. Benefits include:

- Improved corrosion resistance

- Reduced thermal conductivity

- Increased wear resistance

8. Explain the importance of refractory maintenance and how it impacts plant operations.

Regular maintenance of refractory linings is crucial for ensuring optimal plant operations and safety. Proper maintenance practices include:

- Visual inspections

- Temperature monitoring

- Refractory repairs and replacements

- Regular cleaning and debris removal

9. Discuss the latest advancements in refractory materials and technologies.

- Development of ultra-high-temperature ceramics

- Self-healing refractories

- Advanced refractory coatings

- Computational modeling for refractory design and optimization

10. How do you stay updated on the latest developments and best practices in the refractory industry?

- Attend industry conferences and exhibitions

- Read trade publications and technical journals

- Participate in professional organizations and networking events

- Engage in continuous education and training

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Refractory Specialist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Refractory Specialist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Refractory Specialist plays a crucial role in ensuring the efficient operation of industrial furnaces and kilns by specializing in refractory materials.

1. Material Selection and Analysis

Analyze and select appropriate refractory materials for various applications based on factors such as temperature, chemical environment, and mechanical stress.

2. Design and Development

Develop and optimize refractory designs to enhance performance and extend the life of furnaces and kilns.

3. Quality Control and Inspection

Monitor and ensure the quality of refractory materials and installations through rigorous inspection and testing procedures.

4. Troubleshooting and Maintenance

Identify and resolve operational issues related to refractories, including failures, corrosion, and wear.

5. Collaboration and Communication

Collaborate with engineers, operators, and suppliers to optimize refractory performance and provide technical support.

Interview Tips

Preparing for a Refractory Specialist interview requires thorough research and a deep understanding of the industry.

1. Technical Knowledge

Review fundamental concepts of refractory materials, their properties, and applications. Study industry standards and best practices.

2. Case Studies and Examples

Prepare specific examples of refractory projects you have worked on, highlighting your contributions and the impact on operational efficiency.

3. Problem-Solving Abilities

Describe your approach to troubleshooting refractory issues and the methodologies you use to identify and resolve problems effectively.

4. Industry Trends

Keep up-to-date with the latest advancements and research in refractory materials and their applications. Demonstrate your awareness of emerging technologies.

5. Communication and Presentation Skills

Practice presenting technical information clearly and concisely to both technical and non-technical audiences. Highlight your ability to communicate effectively with engineers, operators, and clients.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Refractory Specialist role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.