Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Refractory Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

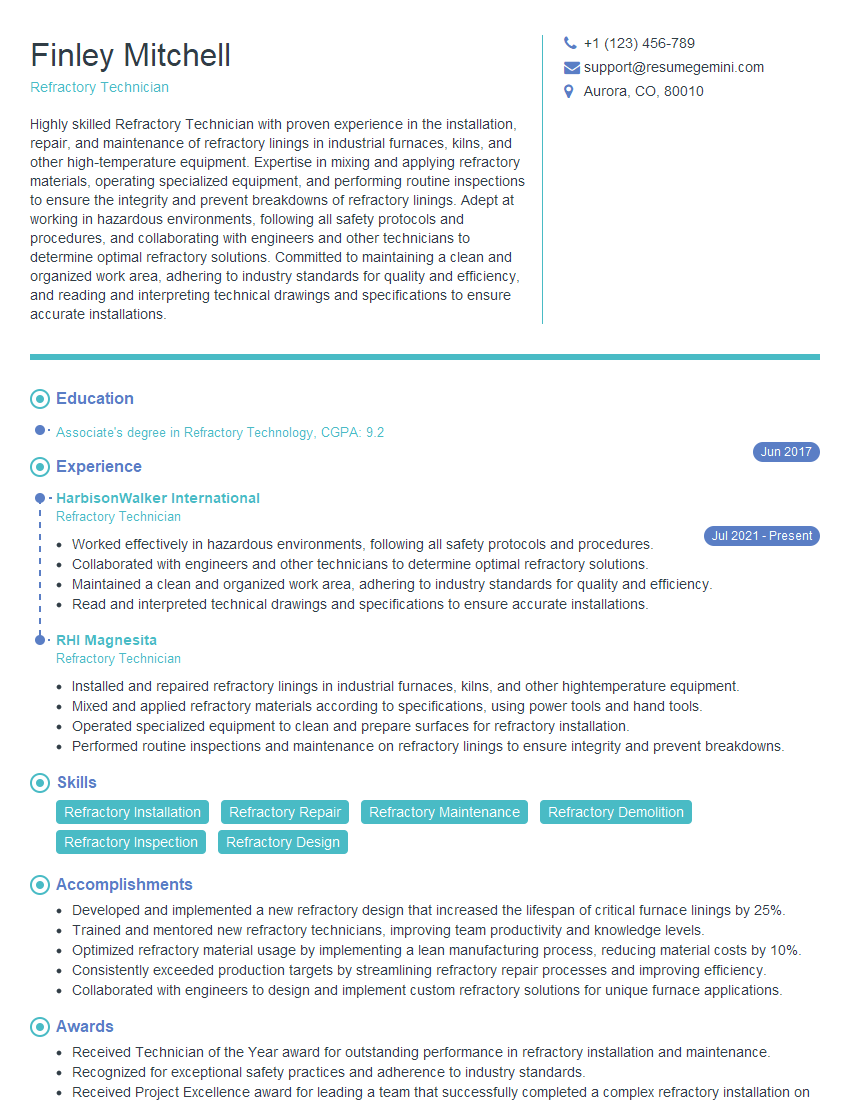

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Refractory Technician

1. What are the different types of refractory materials used in industrial applications?

- Acid refractories: Used in environments with high acid resistance, such as in chemical processing and petrochemicals.

- Basic refractories: Suitable for environments with high alkaline conditions, such as in cement kilns and glass furnaces.

- Neutral refractories: Used in applications where both acid and alkaline resistance is required, such as in incinerators and power plants.

- Insulating refractories: Designed to minimize heat loss and improve energy efficiency in furnaces and other high-temperature applications.

2. Describe the factors to consider when selecting refractory materials for a specific application.

Properties of the materials being processed

- Chemical composition

- Temperature range

- Mechanical and thermal stresses

Furnace operating conditions

- Temperature profile

- Atmosphere (oxidizing, reducing, inert)

- Heating and cooling rates

Cost and availability

3. What techniques are commonly used for refractory installation?

- Laying: Installing refractory bricks or tiles in a specific pattern and bonding them with mortar.

- Casting: Pouring a refractory material into a mold to create a custom shape or component.

- Pneumatic gunning: Spraying a refractory material onto a surface to form a monolithic lining.

- Ramming: Compacting a refractory mixture into place using a mechanical rammer.

4. How do you ensure the integrity and performance of refractory linings?

- Regular inspections to identify any damage or wear.

- Preventive maintenance, such as patching and repairing minor issues.

- Proper installation and monitoring of temperature and pressure.

- Use of protective coatings or sealants to prevent corrosion or erosion.

- Training and certification of technicians in refractory maintenance.

5. What are the common causes of refractory failure?

- Thermal shock due to rapid temperature changes.

- Chemical attack by corrosive materials.

- Mechanical stress from excessive expansion or contraction.

- Improper installation or maintenance.

- Exposure to excessive temperatures beyond the refractory’s rating.

6. How do you troubleshoot and resolve refractory issues?

- Identify the signs and symptoms of the issue.

- Inspect the refractory lining for damage or wear.

- Review operating conditions and material compatibility.

- Consult with refractory manufacturers or experts.

- Implement appropriate repair or replacement measures.

7. What safety precautions should be taken when working with refractory materials?

- Wear appropriate personal protective equipment (PPE), including gloves, respirators, and safety glasses.

- Handle refractory materials with care to avoid dust inhalation.

- Avoid contact with hot refractory surfaces.

- Follow proper storage and disposal procedures.

- Be aware of potential hazards, such as falls and electrical shock.

8. What are the latest advancements in refractory technology?

- Development of high-temperature refractory materials for extreme environments.

- Advanced coatings and sealants for improved corrosion and erosion resistance.

- Use of lightweight and porous refractory materials for energy efficiency.

- Automated inspection and monitoring systems for predictive maintenance.

- Research on sustainable and environmentally friendly refractory materials.

9. How do you stay up-to-date with the latest industry trends and best practices in refractory maintenance?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Participate in online forums and discussions.

- Consult with refractory suppliers and experts.

- Seek opportunities for professional development and training.

10. Why are you interested in working as a Refractory Technician with our company?

- Express enthusiasm for the company’s reputation and industry leadership.

- Highlight your alignment with the company’s values and commitment to excellence.

- Explain how your skills and experience can contribute to the company’s success.

- Demonstrate your eagerness to learn and grow within the organization.

- Convey your passion for refractory technology and its applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Refractory Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Refractory Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Refractory Technicians are responsible for the installation, maintenance, and repair of refractory materials, which are used to line furnaces and other high-temperature equipment. Their key responsibilities include:1. Installation and Repair of Refractory Materials

Refractory Technicians install and repair refractory materials, such as bricks, tiles, and monoliths, in furnaces, boilers, and other high-temperature equipment. They ensure that the materials are properly installed and sealed to prevent heat loss and damage to the equipment.

2. Inspection and Testing of Refractory Materials

Refractory Technicians inspect refractory materials regularly to identify any damage or deterioration. They conduct tests to determine the condition of the materials and recommend maintenance or repair work as needed.

3. Supervision of Refractory Installation and Repair Crews

In some cases, Refractory Technicians supervise refractory installation and repair crews. They provide guidance and ensure that the work is completed to the required standards.

4. Training of New Refractory Technicians

Refractory Technicians may be responsible for training new refractory technicians. They provide instruction on the proper installation, maintenance, and repair of refractory materials.

Interview Tips

To ace an interview for a Refractory Technician position, candidates should prepare thoroughly and follow these tips:1. Research the Company and the Position

Before the interview, candidates should research the company and the specific position they are applying for. This will help them to understand the company’s culture, values, and the specific requirements of the role.

2. Practice Answering Common Interview Questions

Candidates should practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”. They should also be prepared to discuss their experience and qualifications as they relate to the job responsibilities.

3. Highlight Relevant Skills and Experience

In the interview, candidates should highlight their relevant skills and experience. They should emphasize their ability to install, maintain, and repair refractory materials, as well as their knowledge of the different types of refractory materials and techniques.

4. Demonstrate Enthusiasm and Passion

Candidates should demonstrate enthusiasm and passion for the role of Refractory Technician. They should express their interest in working with refractory materials and their desire to learn more about the field.

5. Be Prepared to Ask Questions

At the end of the interview, candidates should be prepared to ask questions about the position and the company. This will show that they are engaged and interested in the opportunity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Refractory Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.