Are you gearing up for an interview for a Refractory Worker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Refractory Worker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

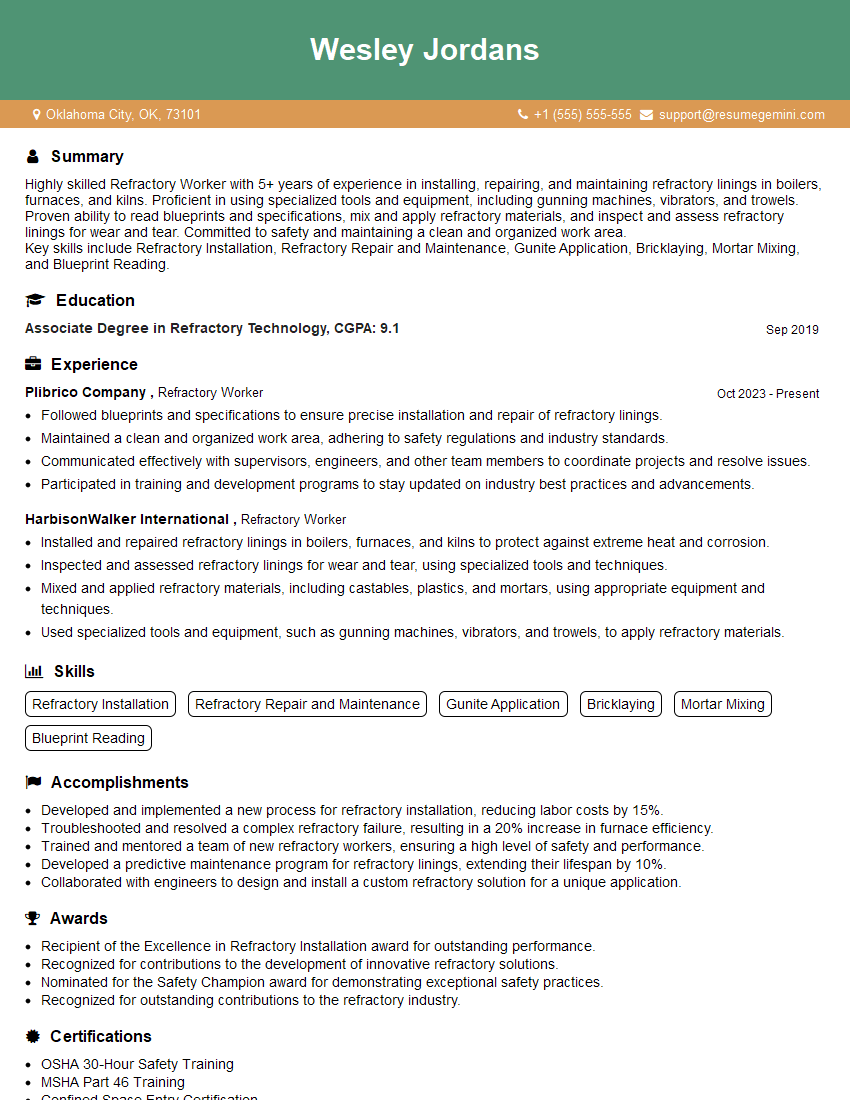

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Refractory Worker

1. Explain how you would prepare and mix refractory materials?

1. Identify the type of refractory material being used and gather the necessary materials. 2. Determine the correct proportions of refractory materials and mix them thoroughly. 3. Add water or other liquids to the mixture and continue mixing until a uniform consistency is achieved. 4. Let the mixture rest for a short period of time to allow the materials to hydrate. 5. Mix the materials again until they are ready to be applied.

2. How do you install refractory materials?

Casting

- Pour the refractory mixture into a mold or form.

- Allow the mixture to set and harden.

Ramming

- Pack the refractory mixture into a confined space using a pneumatic or manual tamper.

- Compact the mixture to create a dense and uniform structure.

Gunning

- Spray the refractory mixture onto a surface using a pneumatic gun.

- Build up the material in layers to create the desired thickness.

3. How do you inspect and test refractory materials?

1. Visual inspection: Check for cracks, voids, or other defects. 2. Dimensional measurement: Verify the shape and size of the refractory materials. 3. Physical testing: Perform tests to determine the strength, density, and thermal conductivity of the materials. 4. Chemical analysis: Analyze the chemical composition of the materials to ensure they meet specifications. 5. Non-destructive testing: Use techniques such as ultrasonic or radiography to identify internal defects.

4. How do you maintain and repair refractory materials?

1. Inspect refractory materials regularly for signs of wear or damage. 2. Repair cracks or voids using appropriate patching materials. 3. Replace damaged or worn refractory materials as needed. 4. Regularly clean and maintain refractory materials to prevent build-up of debris or contamination. 5. Follow manufacturer’s instructions for proper maintenance and repair.

5. How do you handle and store refractory materials safely?

1. Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and respirators. 2. Handle refractory materials carefully to avoid breakage or damage. 3. Store refractory materials in a dry and well-ventilated area. 4. Protect refractory materials from moisture and contamination. 5. Dispose of refractory materials properly according to local regulations.

6. What are the different types of refractory materials and their applications?

- Fireclay bricks: Used in high-temperature applications, such as kilns and furnaces.

- Silica bricks: Used in glass manufacturing and other high-temperature applications.

- Magnesia bricks: Used in steelmaking and other high-temperature applications.

- Chrome-magnesite bricks: Used in high-temperature applications where resistance to slag and corrosion is required.

- Carbon bricks: Used in electric arc furnaces and other applications where high thermal conductivity is required.

7. What are the key properties of refractory materials?

1. High-temperature resistance 2. Thermal conductivity 3. Chemical resistance 4. Mechanical strength 5. Density 6. Porosity

8. What are the challenges of working with refractory materials?

1. High temperatures 2. Harsh chemical environments 3. Complex installation and repair procedures 4. Safety hazards, such as dust and fumes

9. What are the latest advancements in refractory materials technology?

1. Development of new materials with improved properties 2. Advancements in manufacturing techniques 3. Increased use of automation and technology 4. Fokus on sustainability and environmental friendliness

10. What is the future of refractory materials industry?

1. Continued growth in demand for refractory materials due to industrialization and urbanization 2. Increasing focus on energy efficiency and environmental sustainability 3. Development of new materials and technologies to meet the demands of emerging industries 4. Growing importance of automation and digitalization

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Refractory Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Refractory Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Refractory Workers are skilled professionals responsible for installing, repairing, and maintaining refractory materials used in various industrial settings, including furnaces, kilns, and boilers. Their primary role is to ensure the efficient and safe operation of these high-temperature environments.

1. Refractory Material Installation

Install and fit refractory materials such as bricks, tiles, and mortars to line furnaces, kilns, and other high-temperature equipment.

- Follow blueprints, drawings, and specifications to determine material placement and dimensions.

- Use specialized tools and techniques to cut, shape, and lay refractory materials.

2. Refractory Material Repair

Inspect refractory linings for defects, damage, or deterioration and perform necessary repairs.

- Identify areas requiring repair and determine the appropriate materials and methods.

- Remove damaged materials and replace or repair them as needed.

3. Maintenance and Inspection

Carry out regular maintenance and inspection of refractory linings to ensure optimal performance and longevity.

- Check for cracks, spalling, and other signs of wear and tear.

- Clean and repair linings as needed to prevent equipment failure.

4. Safety and Environmental Compliance

Adhere to all safety regulations and environmental policies related to refractory work.

- Wear appropriate personal protective equipment (PPE) when handling hazardous materials.

- Dispose of waste materials in accordance with environmental regulations.

Interview Tips

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This knowledge will help you demonstrate interest and understanding during the interview.

- Visit the company website and review their annual report.

- Read industry news and articles to stay informed about current developments.

2. Practice Your Answers

Prepare for common interview questions by researching and practicing your responses. This will help you speak confidently and clearly during the interview.

- Prepare answers to questions about your experience, skills, and why you’re interested in the position.

- Practice delivering your answers aloud to improve your delivery and clarity.

3. Highlight Your Skills and Experience

Tailor your resume and interview answers to the specific requirements of the job. Highlight your relevant skills and experience that make you a suitable candidate.

- Use the job description as a guide to identify the key qualifications and skills required for the role.

- Provide specific examples from your work experience to demonstrate your proficiency in these areas.

4. Be Prepared to Discuss Your Safety Knowledge

Refractory Work involves handling hazardous materials and working with high-temperature environments. Be prepared to discuss your understanding of safety protocols and procedures.

- Review OSHA regulations and industry standards related to refractory work.

- Explain your experience in using PPE, handling hazardous materials, and following safety guidelines in your previous role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Refractory Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.