Feeling lost in a sea of interview questions? Landed that dream interview for Refrigeration Unit Repairer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Refrigeration Unit Repairer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

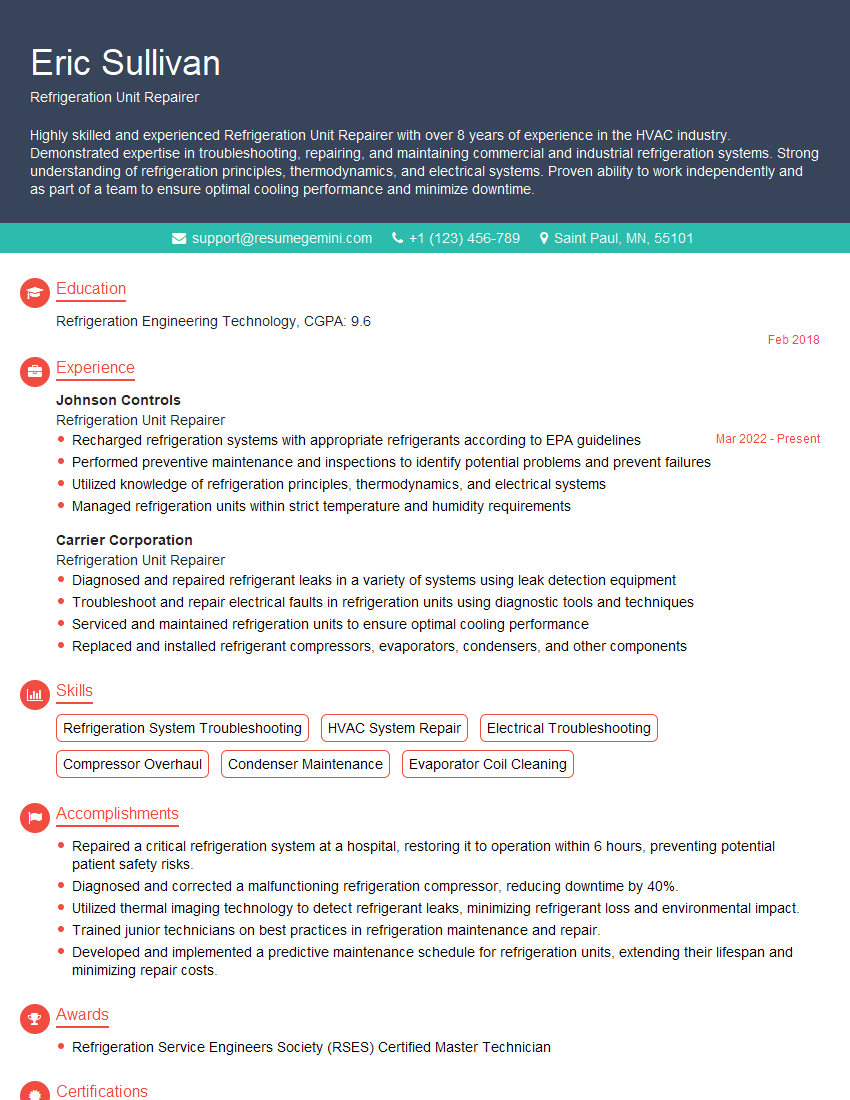

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Refrigeration Unit Repairer

1. How do you troubleshoot a refrigeration system that is not cooling properly?

Answer: * Check the power supply to the unit. * Check the refrigerant level. * Check the condenser coils for dirt or debris. * Check the evaporator coils for ice or frost. * Check the thermostat for proper operation.

2. What are the most common causes of a refrigeration system failure?

- Electrical problems: These can include power outages, blown fuses, or short circuits.

- Refrigerant leaks: These can occur anywhere in the system, and can cause the system to lose its cooling capacity.

- Mechanical problems: These can include worn-out compressors, fans, or other components.

3. How do you test a refrigeration compressor for continuity?

Answer: * Use a multimeter to set the dial to the ohms setting. * Disconnect the power to the compressor. * Touch one probe to the positive terminal of the compressor and the other probe to the negative terminal. * If the multimeter reads zero ohms, the compressor is continuous.

4. How do you braze a refrigeration line?

- Prepare the line: Clean the line with a wire brush or sandpaper to remove any dirt or debris.

- Flux the line: Apply a thin layer of flux to the line.

- Heat the line: Use a torch to heat the line until it is red-hot.

- Apply solder: Touch the solder to the line, and it will flow into the joint.

- Cool the line: Allow the line to cool completely before turning on the refrigeration system.

5. What are the safety precautions that you should take when working on a refrigeration system?

- Wear protective clothing and eyewear.

- Use caution when handling refrigerants.

- Be aware of the electrical hazards associated with refrigeration systems.

- Never work on a refrigeration system that is live.

- Always follow the manufacturer’s instructions when working on a refrigeration system.

6. What are the different types of refrigerants used in refrigeration systems?

- CFCs (chlorofluorocarbons): These were the most common refrigerants used in the past, but they have been phased out due to their ozone-depleting potential.

- HCFCs (hydrochlorofluorocarbons): These refrigerants are less harmful to the ozone layer than CFCs, but they are still being phased out.

- HFCs (hydrofluorocarbons): These refrigerants are not harmful to the ozone layer, but they are still greenhouse gases.

- Natural refrigerants: These refrigerants are naturally occurring substances, such as ammonia or carbon dioxide.

7. What is the purpose of a refrigeration system?

Answer: The purpose of a refrigeration system is to remove heat from a space and transfer it to another space. This is done by circulating a refrigerant through a series of coils and valves. The refrigerant is compressed, which causes it to heat up. The heat is then transferred to the space that needs to be cooled. The refrigerant then expands, which causes it to cool down. The heat is then transferred to the space that needs to be heated.

8. What are the different types of refrigeration systems?

- Direct expansion systems: These systems use a single refrigerant to cool the space. The refrigerant is expanded directly into the evaporator coil.

- Indirect expansion systems: These systems use a secondary fluid to cool the space. The refrigerant is expanded into a heat exchanger, which transfers the heat to the secondary fluid. The secondary fluid is then circulated through the evaporator coil.

- Absorption systems: These systems use a refrigerant and an absorbent to cool the space. The refrigerant is absorbed by the absorbent, which releases heat. The heat is then transferred to the space that needs to be cooled.

9. What are the different components of a refrigeration system?

- Compressor: The compressor compresses the refrigerant, which causes it to heat up.

- Condenser: The condenser transfers the heat from the refrigerant to the space that needs to be cooled.

- Evaporator: The evaporator transfers the heat from the space that needs to be cooled to the refrigerant.

- Expansion valve: The expansion valve controls the flow of refrigerant into the evaporator coil.

10. How do you maintain a refrigeration system?

- Clean the condenser coils: The condenser coils should be cleaned regularly to remove any dirt or debris that could block the airflow.

- Check the refrigerant level: The refrigerant level should be checked regularly to ensure that the system is operating properly.

- Inspect the electrical components: The electrical components should be inspected regularly to ensure that they are in good working order.

- Lubricate the moving parts: The moving parts of the system should be lubricated regularly to ensure that they are operating smoothly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Refrigeration Unit Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Refrigeration Unit Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Refrigeration Unit Repairers play a crucial role in maintaining optimal cooling performance in various industries. Their responsibilities encompass a wide range of tasks, including:

1. Diagnose and Repair Refrigeration Units

Inspect and assess refrigeration units to identify malfunctions, leaks, and other problems.

- Use specialized tools and equipment to pinpoint faulty components.

- Repair or replace compressors, condensers, evaporators, and other parts.

2. Preventative Maintenance and Inspection

Conduct regular inspections and maintenance tasks to minimize breakdowns and extend the lifespan of refrigeration units.

- Check refrigerant levels, clean coils, and lubricate moving parts.

- Identify potential problems and address them promptly.

3. System Installation and Commissioning

Install and commission new refrigeration units according to manufacturer specifications and industry standards.

- Follow safety protocols and adhere to building codes.

- Test and adjust systems to ensure optimal performance.

4. Customer Support and Troubleshooting

Provide technical support to customers and assist with troubleshooting malfunctioning refrigeration units.

- Answer technical inquiries and provide guidance over the phone or email.

- Visit sites to diagnose and resolve issues.

Interview Tips

To ace the interview for a Refrigeration Unit Repairer position, follow these tips and hacks:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and specific job requirements. This will help you tailor your answers and demonstrate your understanding of the role.

- Visit the company website and social media pages.

- Review the job description thoroughly.

2. Highlight Your Technical Expertise

Emphasize your knowledge of refrigeration systems, including compressors, condensers, evaporators, and refrigerants.

- Mention specific tools and equipment you are proficient in using.

- Quantify your experience with repair and maintenance tasks.

3. Demonstrate Problem-Solving Abilities

Share examples of how you diagnosed and resolved complex refrigeration problems. Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Focus on your analytical skills and ability to think critically.

- Describe the specific steps you took and the successful outcomes.

4. Emphasize Customer Service Skills

Highlight your ability to communicate effectively with customers, understand their needs, and provide prompt and courteous service.

- Describe how you handle customer complaints and resolve technical issues.

- Mention any certifications or training in customer service.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Refrigeration Unit Repairer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!