Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Regrinder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

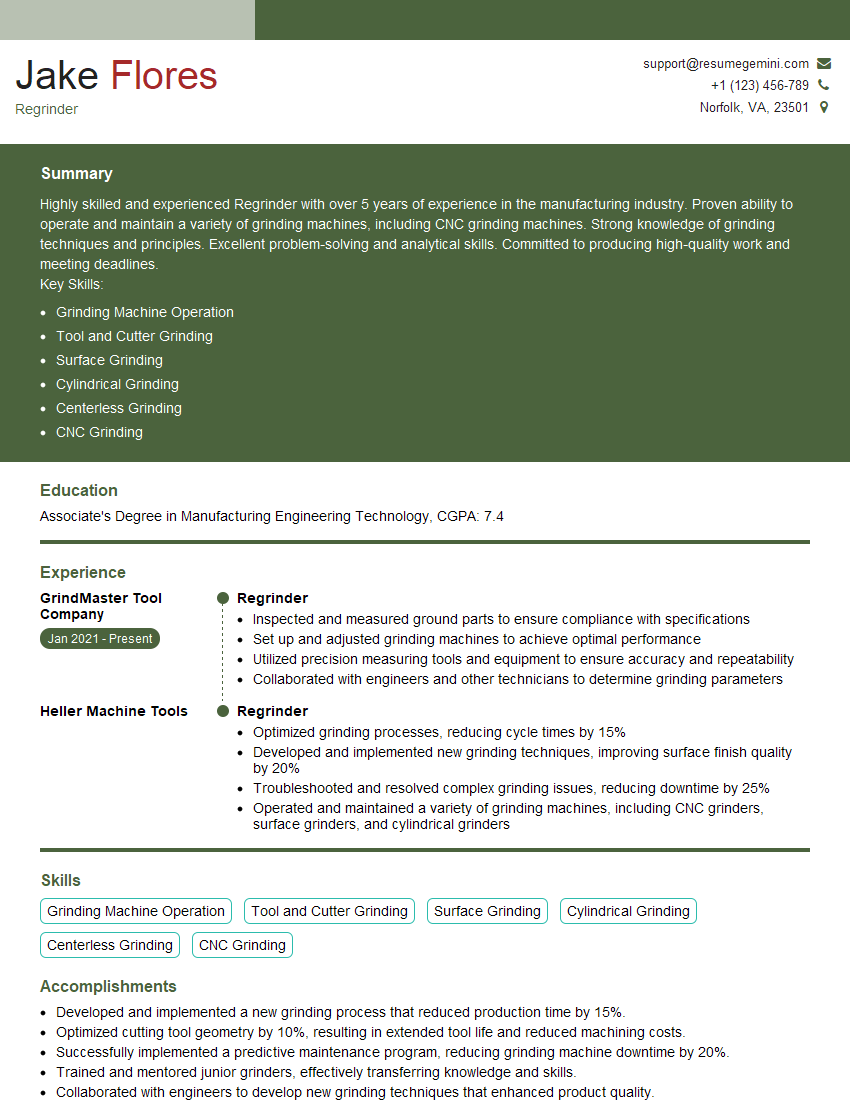

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Regrinder

1. Explain the difference between surface grinding and cylindrical grinding?

- Surface grinding is a process of grinding a flat surface, while cylindrical grinding is a process of grinding a cylindrical surface.

- Surface grinding is typically used to achieve high levels of precision and flatness, while cylindrical grinding is used to achieve high levels of accuracy and roundness.

- Surface grinding is typically performed using a flat grinding wheel, while cylindrical grinding is performed using a cylindrical grinding wheel.

2. What are the different types of grinding wheels?

Abrasive type

- Natural abrasives: such as diamond, corundum, emery, etc.

- Artificial abrasives: such as silicon carbide, cubic boron nitride, etc.

Bonding type

- Vitrified bond: made of glass

- Resin bond: made of synthetic resin

- Metal bond: made of metal

- Ceramic bond: made of ceramic

Structure

- Open structure: suitable for grinding hard and brittle materials

- Dense structure: suitable for grinding soft and ductile materials

3. What are the factors that affect the grinding process?

- Type of grinding wheel

- Workpiece material

- Grinding speed

- Feed rate

- Depth of cut

- Coolant

4. What are the common problems that can occur during grinding?

- Chatter

- Burning

- Glazing

- Loading

- Wheel wear

5. How can you prevent or minimize grinding problems?

- Use the correct grinding wheel for the job

- Use the correct grinding speed and feed rate

- Use a coolant to keep the workpiece and wheel cool

- Dress the grinding wheel regularly

- Inspect the workpiece regularly for signs of problems

6. What are the different types of grinding machines?

- Surface grinding machines

- Cylindrical grinding machines

- Internal grinding machines

- Centerless grinding machines

- CNC grinding machines

7. What are the advantages of using CNC grinding machines?

- Increased accuracy and precision

- Reduced setup times

- Increased productivity

- Improved surface finish

- Reduced operator error

8. What are the different types of grinding fluids?

- Water-soluble oils

- Synthetic coolants

- Straight oils

9. What are the functions of grinding fluids?

- Cool the workpiece and grinding wheel

- Lubricate the grinding wheel and workpiece

- Remove chips and swarf from the grinding area

- Prevent rust and corrosion

10. What are the safety precautions that should be taken when operating a grinding machine?

- Wear eye protection

- Wear hearing protection

- Wear gloves

- Keep the work area clean and free of debris

- Never operate a grinding machine if you are tired or under the influence of alcohol or drugs

11. How do you troubleshoot a grinding machine?

- Check the grinding wheel for damage

- Check the workpiece for damage

- Check the grinding fluid level

- Check the grinding machine settings

- Call a qualified technician if you cannot resolve the problem

12. What are the different types of grinding operations?

- Cylindrical grinding

- Surface grinding

- Internal grinding

- Centerless grinding

- Creep feed grinding

13. What are the advantages of using CBN grinding wheels?

- Increased grinding efficiency

- Improved surface finish

- Reduced grinding forces

- Longer wheel life

14. What are the disadvantages of using CBN grinding wheels?

- Higher cost

- More difficult to dress

- Not suitable for all grinding applications

15. What is the difference between a surface grinder and a cylindrical grinder?

- A surface grinder is used to grind flat surfaces, while a cylindrical grinder is used to grind cylindrical surfaces

- A surface grinder uses a flat grinding wheel, while a cylindrical grinder uses a cylindrical grinding wheel

- A surface grinder is typically used for precision grinding, while a cylindrical grinder is typically used for rough grinding

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Regrinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Regrinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Regrinders play a vital role in maintaining the quality and precision of manufactured products by repairing, modifying, and sharpening cutting tools, dies, and other components.

1. Tool Repair and Modification

Regrinders are responsible for inspecting, repairing, and modifying cutting tools, such as drills, end mills, and reamers.

- Inspect tools for wear, damage, or defects.

- Repair broken tools, braze inserts, and sharpen cutting edges.

- Modify tools to meet specific requirements or specifications.

2. Die Maintenance and Overhaul

Regrinders maintain and overhaul dies used in stamping, forming, and cutting operations.

- Inspect dies for wear, damage, or misalignment.

- Grind and resharpen die surfaces to restore precision.

- Overhaul dies, replacing worn parts and adjusting clearances.

3. Component Grinding

Regrinders grind and finish various components to meet specific tolerances and specifications.

- Grind and polish shafts, pins, and other cylindrical components.

- Grind and finish flat surfaces, such as plates and fixtures.

- Grind and sharpen blades, knives, and cutting edges.

4. Machine Operation and Setup

Regrinders are proficient in operating and setting up grinding machines, such as surface grinders, cylindrical grinders, and tool and cutter grinders.

- Set up and adjust grinding machines according to specifications.

- Load and secure workpieces in the machine.

- Monitor grinding operations and make adjustments as needed.

Interview Preparation Tips

Following are some interview preparation tips to help you ace the interview for a Regrinder position:

1. Research the Company

Before the interview, research the company, its industry, and its products or services.

- Visit the company website, read news articles, and check social media pages.

- Learn about the company’s history, mission, and values.

- Identify any relevant industry trends or developments.

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers.

- Tell me about your experience in tool regrinding.

- What are your strengths and weaknesses as a regrinder?

- Give me an example of a time you resolved a grinding issue.

3. Showcase Your Skills and Experience

Highlight your skills and experience that are relevant to the regrinder role.

- Quantify your accomplishments whenever possible.

- Use specific examples to demonstrate your abilities.

- Prepare questions to ask the interviewer that show your interest in the position and the company.

4. Be Prepared to Discuss Your Knowledge

During the interview, you may be asked questions about your knowledge of grinding techniques, equipment, and materials.

- Review different grinding methods, such as surface grinding, cylindrical grinding, and tool and cutter grinding.

- Be familiar with the types of grinding wheels and their applications.

- Understand the different materials that can be ground, such as metals, ceramics, and plastics.

5. Dress Professionally and Confidently

First impressions matter. Dress professionally and arrive on time for your interview.

- Wear clean and pressed clothing that is appropriate for the work environment.

- Be well-groomed and maintain good hygiene.

- Project confidence and enthusiasm throughout the interview.

Next Step:

Now that you’re armed with the knowledge of Regrinder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Regrinder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini