Are you gearing up for an interview for a Regulator Assembler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Regulator Assembler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

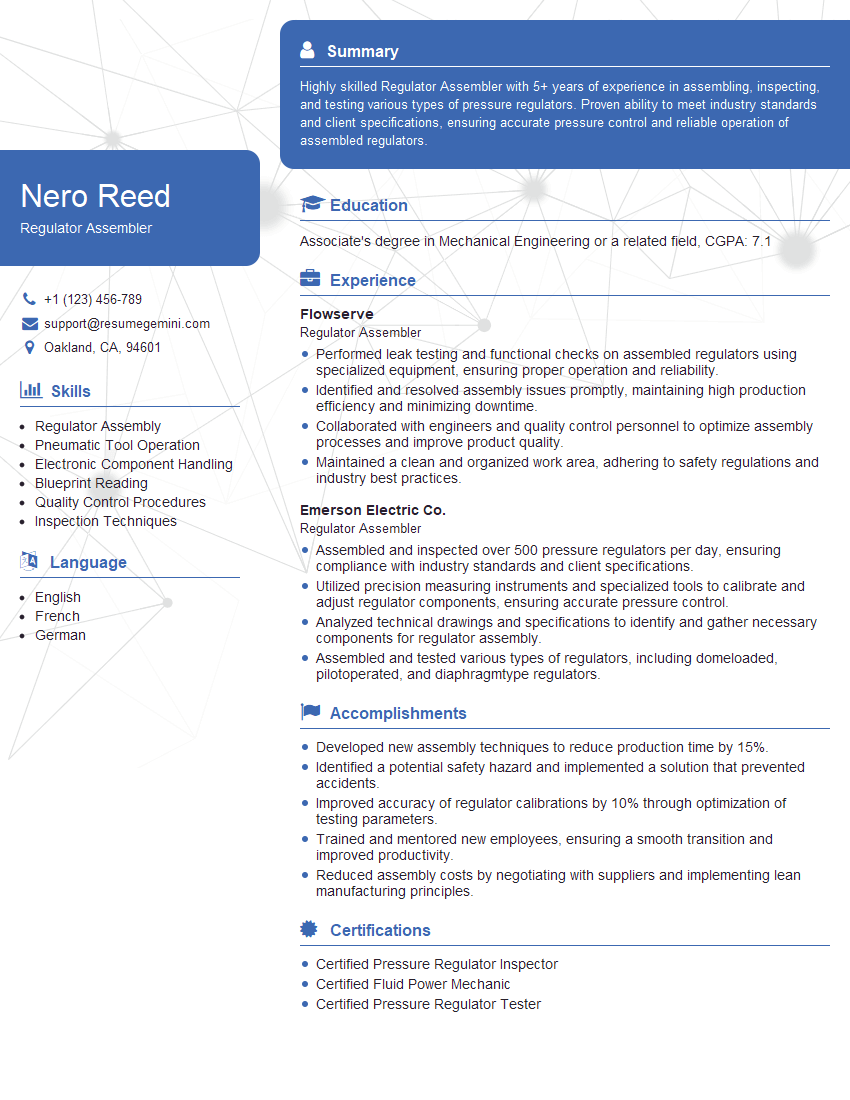

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Regulator Assembler

1. Explain the process of assembling a pressure regulator?

Assembling a pressure regulator involves the following steps:

- Inspect and clean all components.

- Install the diaphragm and spring assembly.

- Connect the body and bonnet.

- Install the inlet and outlet connections.

- Adjust the spring to the desired pressure setting.

- Test the regulator for leaks and proper operation.

2. What are the different types of pressure regulators and their applications?

Diaphragm Regulators:

- Used for low to medium pressure applications.

- Diaphragm separates the inlet and outlet chambers.

- Suitable for gas and liquid applications.

Piston Regulators:

- Used for high-pressure applications.

- Piston moves in a cylinder to control pressure.

- Provides precise pressure regulation.

Pilot-Operated Regulators:

- Maintains pressure by sensing a pilot signal.

- High accuracy and stability.

- Used for critical applications.

3. How do you troubleshoot a faulty pressure regulator?

- Check for leaks using soapy water or a leak detector.

- Inspect the diaphragm or piston for damage or wear.

- Verify the spring setting and adjust if necessary.

- Clean or replace clogged or contaminated components.

- Check the inlet and outlet pressure gauges for correct readings.

4. What safety precautions should be taken when working with pressure regulators?

- Wear appropriate personal protective equipment (PPE).

- Use proper tools and procedures for handling pressurized systems.

- Vent pressure before disassembling or servicing.

- Do not exceed the maximum pressure rating of the regulator.

- Follow manufacturer’s instructions for safe operation and maintenance.

5. How do you ensure the accuracy of pressure regulator calibration?

- Use a certified pressure gauge for calibration.

- Calibrate the regulator according to manufacturer’s specifications.

- Test the regulator at multiple pressure points to verify accuracy.

- Document the calibration results for traceability.

- Periodically re-calibrate the regulator to maintain accuracy.

6. What are the common materials used in pressure regulator construction?

- Brass or 316 stainless steel for body and bonnet.

- Neoprene or silicone for diaphragms.

- 17-4PH stainless steel for springs.

- Polytetrafluoroethylene (PTFE) for seals.

- Buna-N or Viton for O-rings.

7. How do you prevent corrosion and erosion in pressure regulators?

- Use corrosion-resistant materials such as stainless steel.

- Apply protective coatings or finishes.

- Avoid exposure to corrosive environments.

- Flush the regulator with compatible fluids to remove contaminants.

- Inspect and replace worn or damaged components promptly.

8. What are the performance characteristics of a good pressure regulator?

- High accuracy and stability.

- Wide pressure range.

- Low hysteresis.

- Fast response time.

- Long service life.

- Reliability and durability.

- Low maintenance requirements.

9. What industry standards apply to pressure regulator assembly?

- ANSI/ASME B40.100

- ASME Boiler and Pressure Vessel Code

- NFPA 70 (National Electrical Code)

- ISA-S75.01

- API 614

10. How do you maintain documentation and records for pressure regulator assembly?

- Maintain assembly and calibration logs.

- Record pressure test results.

- Keep track of parts and materials used.

- Archive documentation for traceability and compliance purposes.

- Provide documentation to customers as required.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Regulator Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Regulator Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Regulator Assemblers are responsible for assembling and testing regulators, which are devices used to control the flow of fluids and gases.

1. Assembly

Assembling regulators involves following blueprints and schematics to put together the various components of the device. This may include tasks such as:

- Attaching diaphragms and springs to the regulator body

- Connecting tubes and fittings

- Installing sensors and other components

2. Testing

Once the regulator is assembled, it must be tested to ensure that it is functioning properly. This may involve:

- Performing pressure tests to check for leaks

- Adjusting the regulator to meet specifications

- Calibrating the regulator to ensure accuracy

3. Troubleshooting

If a regulator is not functioning properly, the Regulator Assembler may need to troubleshoot the problem. This may involve:

- Identifying the source of the problem

- Repairing or replacing damaged components

- Adjusting the regulator to correct the problem

4. Quality Control

Regulator Assemblers are also responsible for ensuring that the regulators they assemble meet quality standards. This may involve:

- Inspecting regulators for defects

- Rejecting regulators that do not meet specifications

- Documenting the quality control process

Interview Tips

Preparing for an interview for a Regulator Assembler position requires a combination of technical knowledge and soft skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, which you can then reflect in your answers during the interview. Additionally, it will give you a better understanding of the specific requirements of the role, which you can use to tailor your answers and highlight your relevant skills and experience.

2. Practice Your Answers

One of the best ways to prepare for an interview is to practice your answers to common interview questions. This will help you feel more confident and prepared during the actual interview. Some common questions that you may be asked include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Describe your experience with assembling and testing regulators.

- How do you handle troubleshooting problems with regulators?

3. Be Yourself

It is important to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest about your skills and experience, and let your personality shine through.

4. Dress Professionally

First impressions matter, so make sure you dress professionally for the interview. This means wearing clean, pressed clothes that are appropriate for the office environment. Avoid wearing casual clothing or clothing that is too revealing.

5. Be Punctual

Punctuality is important, so make sure you arrive for the interview on time. If you are running late, be sure to call or email the interviewer to let them know. Additionally, be sure to give yourself plenty of time to get to the interview location so that you are not stressed or flustered when you arrive.

Next Step:

Now that you’re armed with the knowledge of Regulator Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Regulator Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini