Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Reheater interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Reheater so you can tailor your answers to impress potential employers.

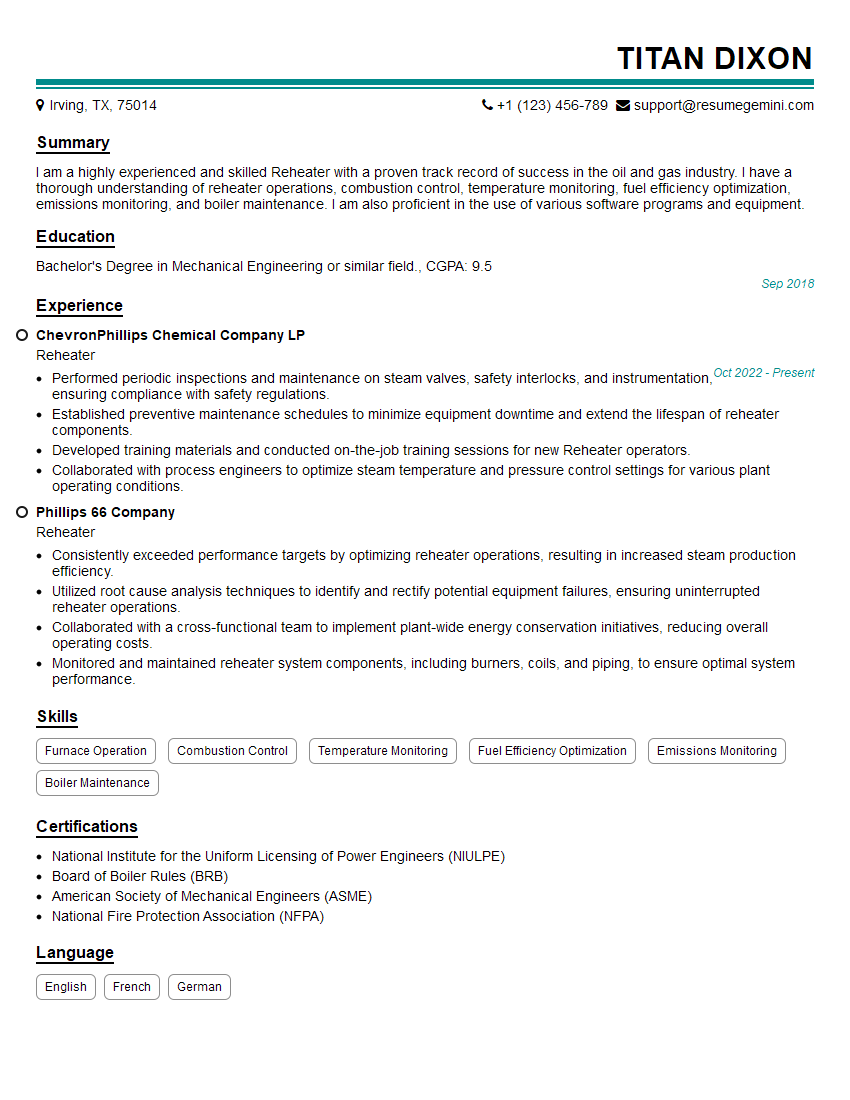

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reheater

1. What are the different types of reheaters and their applications?

There are three different types of reheaters, and each has its own unique applications.

- Direct-fired reheaters are used to heat air or gas directly using a burner. These reheaters are commonly used in industrial applications, such as drying and curing ovens, and in power plants to reheat steam.

- Indirect-fired reheaters use a heat exchanger to transfer heat from a hot fluid to the air or gas being reheated. These reheaters are often used in applications where the air or gas being reheated is contaminated or where direct contact with the combustion gases is not desired.

- Electric reheaters use electricity to heat the air or gas being reheated. These reheaters are often used in applications where precise temperature control is required, such as in laboratories and clean rooms.

2. What are the factors that affect the efficiency of a reheater?

Design factors

- The type of reheater

- The size of the reheater

- The materials used in the construction of the reheater

Operating factors

- The temperature of the air or gas being reheated

- The flow rate of the air or gas being reheated

- The pressure of the air or gas being reheated

3. What are the common problems that can occur with reheaters and how can they be prevented?

Some of the most common problems that can occur with reheaters include:

- Fouling is the buildup of deposits on the heat transfer surfaces of the reheater. This can reduce the efficiency of the reheater and can lead to overheating. Fouling can be prevented by using a clean fuel, by maintaining the proper air-to-fuel ratio, and by cleaning the reheater regularly.

- Corrosion is the deterioration of the metal components of the reheater due to exposure to corrosive gases or liquids. This can weaken the reheater and can lead to leaks. Corrosion can be prevented by using corrosion-resistant materials, by protecting the reheater from corrosive environments, and by maintaining the proper pH level of the water or gas being reheated.

- Overheating is a condition in which the temperature of the air or gas being reheated exceeds the design temperature of the reheater. This can damage the reheater and can create a safety hazard. Overheating can be prevented by using a properly sized reheater, by maintaining the proper air-to-fuel ratio, and by monitoring the temperature of the air or gas being reheated.

4. What are the safety precautions that should be taken when operating a reheater?

- Never operate a reheater without first reading and understanding the manufacturer’s instructions.

- Always wear appropriate personal protective equipment (PPE) when operating a reheater.

- Never operate a reheater in a confined space without adequate ventilation.

- Never use a reheater to heat flammable or explosive materials.

- Always inspect the reheater before each use to ensure that it is in good working condition.

- Never operate a reheater with a damaged or leaking heat exchanger.

- Always monitor the temperature of the air or gas being reheated to ensure that it does not exceed the design temperature of the reheater.

- Never leave a reheater unattended while it is in operation.

- Always turn off the reheater and allow it to cool down before servicing or storing it.

5. What are the maintenance procedures that should be performed on a reheater?

- Regularly inspect the reheater for signs of fouling, corrosion, or overheating.

- Clean the reheater regularly to remove any deposits that may have accumulated on the heat transfer surfaces.

- Check the air-to-fuel ratio of the reheater regularly to ensure that it is operating at the optimal efficiency.

- Monitor the temperature of the air or gas being reheated regularly to ensure that it does not exceed the design temperature of the reheater.

- Service the reheater according to the manufacturer’s instructions.

- Store the reheater in a dry, clean place when it is not in use.

6. What are the advantages of using a reheater?

- Reheaters can improve the efficiency of a heating system by reducing the amount of energy required to heat the air or gas.

- Reheaters can improve the performance of a heating system by providing a more uniform temperature distribution.

- Reheaters can reduce the size and weight of a heating system.

- Reheaters can extend the life of a heating system.

7. What are the disadvantages of using a reheater?

- Reheaters can be expensive to purchase and install.

- Reheaters can require regular maintenance.

- Reheaters can be a safety hazard if they are not operated properly.

8. What are the key factors to consider when selecting a reheater?

- The type of application

- The size of the application

- The temperature requirements of the application

- The efficiency requirements of the application

- The cost of the reheater

9. What are the latest trends in reheater technology?

- The development of more efficient reheaters

- The development of more compact reheaters

- The development of reheaters that are more resistant to fouling and corrosion

- The development of reheaters that are more user-friendly

- The development of reheaters that are more affordable

10. What are your thoughts on the future of reheater technology?

I believe that the future of reheater technology is very bright. I believe that we will see the development of even more efficient, compact, durable, and affordable reheaters in the years to come.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reheater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reheater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Reheater is responsible for maintaining and monitoring the functionality of reheaters in power plants, ensuring the optimal performance of the plant’s steam cycle. Key job responsibilities include:

1. Equipment Maintenance

Inspecting, cleaning, and lubricating reheaters

- Conducting routine maintenance and repairs

- Troubleshooting and diagnosing equipment malfunctions

2. Performance Monitoring

Monitoring reheaters’ temperature, pressure, and flow parameters

- Analyzing data to identify performance trends and deviations

- Ensuring adherence to operating standards

3. Data Analysis

Gathering and analyzing data on reheaters’ performance

- Identifying areas for improvement and optimization

- Preparing reports and presenting findings

4. Emergency Response

Responding to emergency situations involving reheaters

- Implementing corrective actions to minimize damage

- Coordinating with other plant personnel

Interview Tips

To prepare for an interview for a Reheater position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s operations and the specific requirements of the Reheater role.

- Visit the company website and read industry publications.

- Review the job description carefully to identify key responsibilities and qualifications

2. Highlight Relevant Experience and Skills

Emphasize your experience in maintaining and monitoring reheaters or similar equipment.

- Quantify your accomplishments and provide specific examples of your technical abilities.

- Discuss your knowledge of reheaters’ operating principles and troubleshooting techniques

3. Demonstrate Problem-Solving Abilities

Share examples of how you have successfully resolved reheaters’ performance issues.

- Explain your analytical approach and how you identified the root cause of problems.

- Highlight your ability to think critically and find innovative solutions.

4. Emphasize Safety and Attention to Detail

Stress your commitment to safety and adherence to operating procedures.

- Provide examples of your proactive approach to safety and risk management

- Explain your attention to detail and accuracy in monitoring and maintaining equipment.

Next Step:

Now that you’re armed with the knowledge of Reheater interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Reheater positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini