Feeling lost in a sea of interview questions? Landed that dream interview for Reinforcing Metal Worker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Reinforcing Metal Worker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

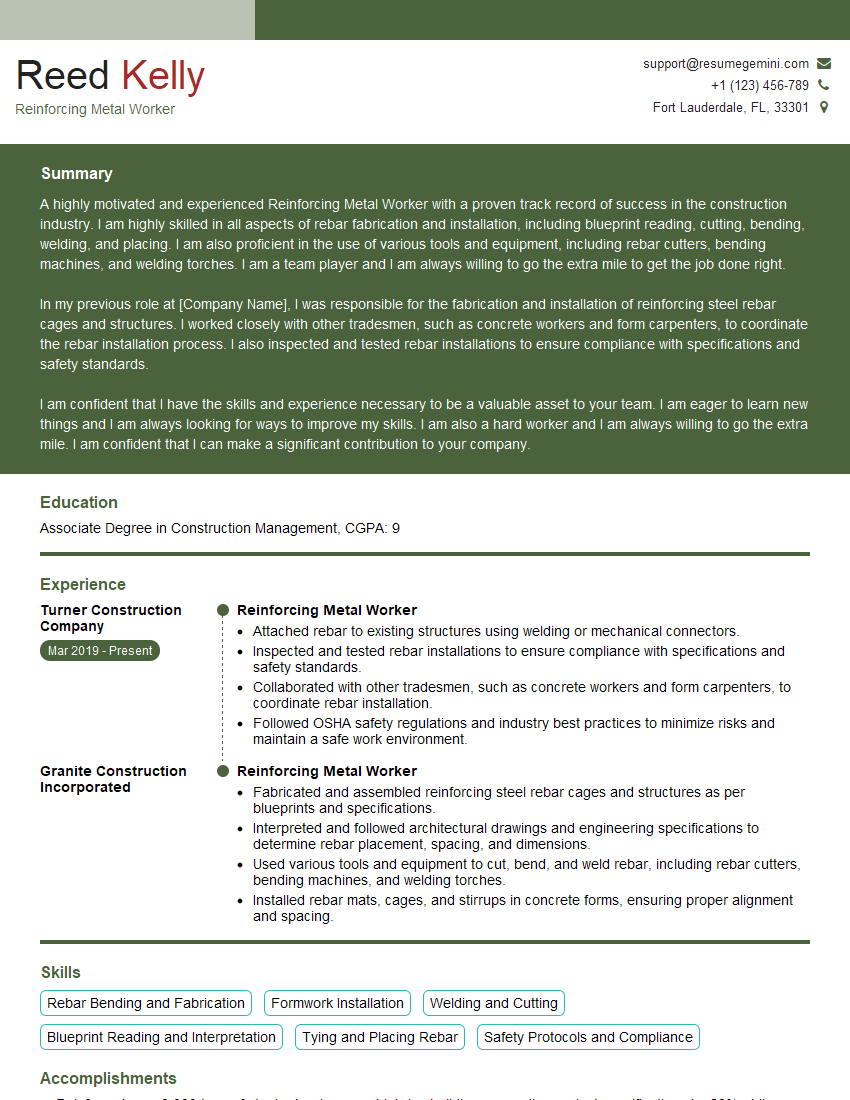

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reinforcing Metal Worker

1. How do you determine the size and quantity of rebar needed for a project?

- Review project blueprints and specifications to determine the size and grade of rebar required.

- Calculate the total linear footage of rebar needed based on the dimensions and spacing requirements specified in the plans.

- Adjust calculations for bends, hooks, and other modifications as specified in the drawings.

- Determine the total weight of rebar required based on the size and quantity of rebar needed.

- Consider factors such as concrete cover, bar spacing, and lap lengths to ensure adequate reinforcement.

2. What techniques do you use to ensure the proper placement and spacing of rebar?

1: Measuring and Layout

- Use measuring tools such as tapes, levels, and squares to accurately position and space rebar.

- Establish reference points and gridlines to ensure consistent spacing and alignment.

- Create bending schedules and templates to ensure proper bending and placement.

Subheading 2: Support and Securing

- Use rebar chairs, spacers, and tie wire to support and maintain the spacing of rebar.

- Check and adjust supports regularly to prevent movement or misalignment during concrete placement.

- Secure rebar to formwork using wire ties to prevent displacement.

3. How do you handle and store rebar safely?

- Wear appropriate safety gear, including gloves and hard hats, when handling rebar.

- Use proper lifting techniques and equipment to prevent injuries.

- Store rebar in designated areas and secure it to prevent falling or rolling.

- Inspect rebar regularly for damage or corrosion, and replace or repair as necessary.

- Keep rebar clean and free of debris to ensure proper bonding with concrete.

4. What are the different types of rebar connections and how do you select the appropriate type for a specific application?

- Lap Splices: Used to connect rebar end-to-end by overlapping them for a specified length.

- Butt Splices: Joined end-to-end with mechanical couplers or welding, providing a stronger connection.

- Mechanical Connections: Use coupler devices to join rebar, providing a quick and reliable method.

- Welded Connections: Permanent connections made by welding rebar together, requiring specialized equipment and skills.

- Selection factors include load requirements, bar size, concrete cover, and environmental conditions.

5. What are the quality control procedures you follow to ensure the accuracy and integrity of your work?

- Verify rebar size, grade, and quantity against project specifications.

- Inspect rebar for damage or corrosion before installation.

- Check rebar placement, spacing, and support against approved drawings.

- Ensure proper connection methods and splicing techniques are used.

- Conduct regular inspections during and after concrete placement to identify any errors or defects.

6. How do you work effectively as part of a construction team?

- Communicate effectively with other trades, supervisors, and engineers.

- Collaborate to resolve issues and ensure a smooth workflow.

- Follow safety protocols and contribute to a positive work environment.

- Maintain a flexible attitude and adapt to changing project requirements.

- Respect and support other team members, regardless of their roles.

7. How do you stay updated on industry best practices and advancements in reinforcing techniques?

- Attend industry conferences, seminars, and workshops.

- Read trade publications and technical journals.

- Seek training opportunities from manufacturers and industry organizations.

- Network with other professionals in the field.

- Stay informed about new materials, technologies, and regulations.

8. Can you describe a challenging project you worked on and how you overcame the obstacles?

- Provide a brief description of the project and the challenges encountered.

- Explain the steps taken to analyze the situation and develop solutions.

- Highlight the specific techniques or methods used to overcome the obstacles.

- Describe the outcome of the project and how your actions contributed to its success.

9. What are your strengths and weaknesses as a Reinforcing Metal Worker?

-

Strengths:

- Proficient in rebar placement, bending, and splicing techniques.

- Strong understanding of construction drawings and specifications.

- Excellent attention to detail and accuracy.

- Physical strength and endurance for handling heavy materials. Weaknesses:

- Limited experience with specialized reinforcing systems (e.g., post-tensioning).

- Working in extreme weather conditions can be challenging.

10. Why are you interested in working for our company?

- Research the company’s reputation, projects, and values.

- Highlight your skills and experience that align with the company’s needs.

- Express enthusiasm for the opportunity to contribute to the company’s success.

- Show that you are genuinely interested in the company’s mission and goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reinforcing Metal Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reinforcing Metal Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Reinforcing Metal Workers are responsible for the installation and maintenance of reinforcing steel in concrete structures. Their key job responsibilities include:

1. Preparation and Planning

Interpreting blueprints and specifications to determine the type and quantity of reinforcing steel required.

- Establishing gridlines and benchmarks to guide the placement of reinforcing steel.

- Preparing the job site by removing obstacles and ensuring a safe work environment.

2. Installation and Fabrication

Cutting, bending, and shaping reinforcing steel according to specifications.

- Assembling and tying reinforcing steel into cages or mats.

- Placing and securing reinforcing steel within concrete forms.

- Inspecting and ensuring the proper placement and spacing of reinforcing steel.

3. Welding and Fastening

Welding reinforcing steel using specialized equipment.

- Using mechanical fasteners, such as bolts or wire ties, to secure reinforcing steel.

- Ensuring welds and fastenings meet industry standards for strength and durability.

4. Inspection and Quality Assurance

Inspecting reinforcing steel installations to ensure they meet specifications.

- Identifying and correcting any discrepancies or defects.

- Documenting inspections and providing quality control reports.

5. Safety and Compliance

Following safety protocols and regulations related to the handling and installation of reinforcing steel.

- Wearing appropriate personal protective equipment (PPE).

- Using tools and equipment properly and safely.

Interview Tips

To ace the interview for a Reinforcing Metal Worker position, candidates should prepare thoroughly and demonstrate their skills and experience. Here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, services, and culture. Review the job description thoroughly to understand the specific responsibilities and requirements.

- Research the industry and current trends related to reinforcing metal work.

- Identify the skills and qualifications that the company is seeking in a candidate.

2. Highlight Relevant Skills and Experience

Emphasize your experience in reinforcing steel installation, fabrication, welding, and inspection. Quantify your accomplishments with specific examples and metrics.

- Discuss any certifications or licenses you hold that demonstrate your proficiency.

- Share examples of projects where you successfully resolved challenges or implemented innovative solutions.

3. Prepare for Technical Questions

Expect questions related to your technical knowledge and ability. Be prepared to discuss different types of reinforcing steel, installation methods, and welding techniques.

- Practice answering questions about industry standards and codes.

- Review common construction terms and materials related to reinforcing metal work.

4. Demonstrate Safety Awareness

Reinforcing Metal Workers must prioritize safety in their work. Highlight your commitment to safety and your understanding of industry regulations.

- Discuss your experience with using PPE and following safety protocols.

- Explain your knowledge of hazardous materials and how you handle them safely.

5. Show Enthusiasm and a Learning Mindset

Convey your passion for reinforcing metal work and your willingness to learn and grow. Express your interest in staying up-to-date with industry advancements.

- Share any training or workshops you have attended to enhance your skills.

- Discuss your goals for professional development and how you plan to stay proficient.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Reinforcing Metal Worker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.