Are you gearing up for an interview for a Remelter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Remelter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

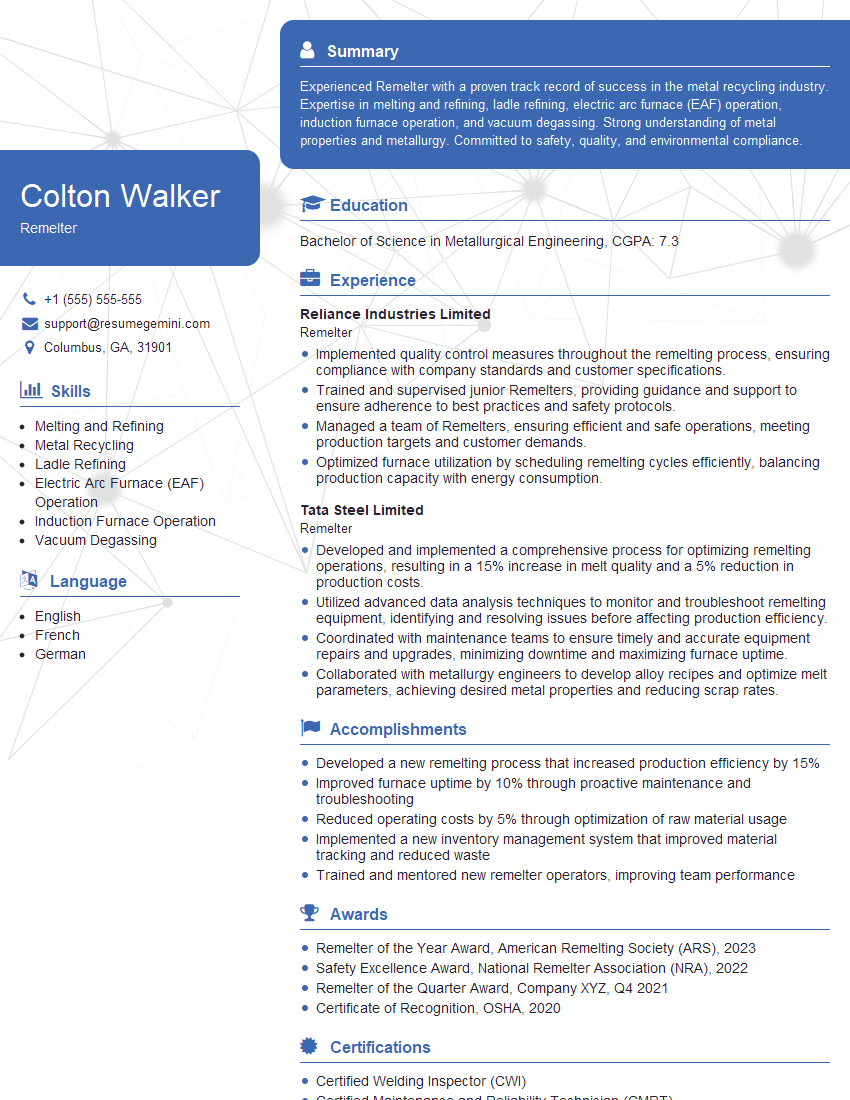

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Remelter

1. Describe your understanding of the remelting process and its importance in the metal industry.

The remelting process is a crucial step in the metal industry that involves transforming scrap or recycled metal into a reusable form. It plays a vital role in various aspects:

- Resource Conservation: Remelting scrap metal reduces the need for mining raw materials, conserving natural resources.

- Cost-Effectiveness: Using recycled metal is significantly more economical than extracting and refining new metal.

- Environmental Sustainability: Remelting reduces waste and emissions associated with mining and primary metal production.

- Improved Properties: Some metals, like aluminum, can benefit from the remelting process, resulting in enhanced strength and durability.

2. Explain the different types of remelting furnaces and their respective advantages and disadvantages.

Electric Arc Furnaces (EAFs)

- Advantages: High efficiency, low emissions, flexibility in feed materials.

- Disadvantages: High energy consumption, electrode erosion.

Induction Furnaces

- Advantages: Precise temperature control, no electrode consumption, clean melt.

- Disadvantages: Limited capacity, higher capital cost.

Reverberatory Furnaces

- Advantages: Can handle large volumes, suitable for non-ferrous metals.

- Disadvantages: Lower efficiency, higher fuel consumption.

3. Discuss the key factors that influence the quality of remelted metal.

- Feedstock Composition: Impurities in scrap metal can affect the final product’s properties.

- Melting Temperature: Accurate temperature control is essential to prevent over- or under-melting.

- Oxidation Control: Minimizing oxygen exposure reduces metal loss and improves purity.

- Fluxing: Chemical additives remove impurities and enhance metal fluidity.

- Cooling Rate: Controlled cooling promotes grain refinement and desired mechanical properties.

4. Describe the safety protocols and environmental considerations associated with remelting operations.

- Personal Protective Equipment (PPE): Heat-resistant clothing, gloves, and respirators are essential.

- Proper Ventilation: Adequate ventilation removes harmful fumes and gases.

- Waste Management: Slag and dross should be properly disposed of or recycled.

- Emissions Control: Baghouse filters or scrubbers minimize air pollution.

- Spill Prevention and Control: Procedures for handling molten metal spills must be in place.

5. Explain the role of flux in the remelting process and discuss different types of fluxes used.

Flux acts as a cleansing agent in the remelting process:

- Removes Impurities: Flux reacts with oxides, sulfides, and other impurities to form a slag that floats to the surface.

- Enhances Fluidity: Flux lowers the melting point of impurities, promoting their removal.

- Protects Metal from Oxidation: Flux covers the molten metal, preventing it from reacting with atmospheric oxygen.

Common types of fluxes include:

- Acid Fluxes: Silica-based fluxes that remove basic oxides.

- Basic Fluxes: Lime-based fluxes that remove acidic oxides.

- Neutral Fluxes: Mixtures of acid and basic fluxes, used for a wide range of applications.

6. Describe the process of degassing molten metal and explain its importance.

Degassing involves removing dissolved gases from molten metal:

- Methods: Vacuum degassing, inert gas purging, and ultrasonic degassing are common methods.

- Importance: Degassing improves metal properties by:

- Reducing porosity and improving weldability.

- Enhancing electrical and thermal conductivity.

- Minimizing internal stresses and defects.

7. Discuss the techniques used to control the solidification of remelted metal and its impact on final product properties.

- Directional Solidification: Controlled cooling promotes the growth of crystals in a preferred direction, resulting in improved mechanical strength.

- Rapid Solidification: Quenching molten metal rapidly leads to finer grain structures, enhancing hardness and wear resistance.

- Controlled Atmospheres: Inert or reducing atmospheres prevent oxidation or decarburization during solidification, affecting the final composition and properties.

8. Explain the importance of quality control in remelting operations and describe the methods used to ensure product quality.

- Chemical Analysis: Spectrometers are used to analyze the composition of feedstock and final products.

- Mechanical Testing: Tensile tests, hardness tests, and fatigue tests evaluate the mechanical properties of remelted metal.

- Non-Destructive Testing (NDT): Ultrasound, radiography, and liquid penetrant testing detect internal flaws and defects.

- Process Monitoring: Temperature sensors, gas analyzers, and flux flowrate monitors ensure optimal process conditions.

9. Describe your experience in optimizing remelting operations and discuss the techniques you have used to improve yield and reduce costs.

I have successfully implemented several optimization strategies in my previous role, including:

- Feedstock Management: Segregating scrap metal based on composition to minimize impurities and improve melt quality.

- Temperature Optimization: Fine-tuning melting temperatures to achieve the desired metal properties while minimizing energy consumption.

- Flux Optimization: Adjusting flux composition and addition rates to improve slag removal and metal quality.

- Process Automation: Implementing sensors and control systems to automate furnace operations and enhance consistency.

10. How would you approach troubleshooting a problem related to excessive slag formation in the remelting furnace?

- Identify the Root Cause: Determine if the issue is related to feedstock composition, furnace temperature, flux type, or other factors.

- Adjust Feedstock: Modify the scrap blend to reduce the presence of impurities that contribute to slag formation.

- Optimize Melting Conditions: Adjust furnace temperature and melting time to minimize oxidation and slag formation.

- Review Flux Composition: Ensure the flux is appropriate for the feedstock and melting conditions. Adjust the flux addition rate as needed.

- Inspect Furnace Equipment: Check for any issues with furnace lining, burners, or other components that may contribute to excessive slag formation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Remelter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Remelter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Remelter is responsible for operating and maintaining remelting furnaces and equipment in a foundry or metalworking facility. Their primary task is to melt down scrap metal and cast new metal products according to specifications.

1. Furnace Operation

Remelters are experts in operating and controlling remelting furnaces. They ensure that the furnaces are operating at the correct temperature and conditions to achieve the desired melt quality.

- Monitor and adjust furnace temperature, pressure, and gas flow

- Load and unload scrap metal into the furnace

- Skim and remove impurities from the molten metal

2. Metal Casting

Remelters also play a crucial role in casting molten metal into new products. They work closely with mold makers to create molds that meet the specified dimensions and shapes.

- Prepare and inspect molds for casting

- Pour molten metal into molds

- Control cooling and solidification processes

3. Quality Control

Remelters are responsible for ensuring that the melted metal meets the required specifications and industry standards. They conduct various tests and inspections to monitor the quality of the metal.

- Take samples of molten metal for analysis

- Inspect castings for defects and imperfections

- Maintain records of melt quality and production data

4. Equipment Maintenance

Remelters are also responsible for maintaining and repairing the remelting equipment. They perform regular inspections, identify potential issues, and conduct routine maintenance to ensure optimal performance.

- Inspect and clean furnaces, crucibles, and other equipment

- Troubleshoot and resolve equipment malfunctions

- Follow safety protocols and maintain a clean and organized work area

Interview Tips

Preparing thoroughly for an interview as a Remelter can significantly increase your chances of success. Here are some key tips and hacks to help you ace the interview:

1. Research the Company and Position

Take the time to thoroughly research the company and the specific position you are applying for. This demonstrates your interest and enthusiasm for the role. Understand the company’s history, culture, products or services, and industry standing. Also, carefully review the job description to identify the key requirements and responsibilities.

- Visit the company’s website and social media pages

- Read industry news and articles related to the company and the remelting industry

- Connect with current or former employees on LinkedIn to gain insights

2. Showcase Your Technical Skills and Experience

Emphasize your technical skills and experience relevant to the Remelter position. Highlight your ability to operate and maintain remelting furnaces, conduct metal casting processes, and ensure quality control. Provide specific examples and quantify your accomplishments whenever possible.

- Describe your experience with different types of remelting furnaces and casting techniques

- Share examples of how you have improved melt quality or production efficiency

- Mention any certifications or training programs you have completed in the field

3. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that showcase your skills and qualifications. Some common questions you may encounter include:

- “Tell us about your experience in operating and maintaining remelting furnaces.”

- “How do you ensure that the melted metal meets the required specifications?”

- “Can you describe your experience in metal casting and mold preparation?”

4. Highlight Your Safety and Environmental Awareness

Remelting involves working with molten metal and potentially hazardous materials. Emphasize your understanding of safety protocols and environmental regulations related to the role. Explain how you ensure a safe and compliant work environment.

- Discuss your knowledge of personal protective equipment (PPE) and safety procedures

- Explain how you handle and dispose of hazardous materials properly

- Mention any environmental initiatives or certifications you are familiar with

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Remelter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!