Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Remote Continuous Mining Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

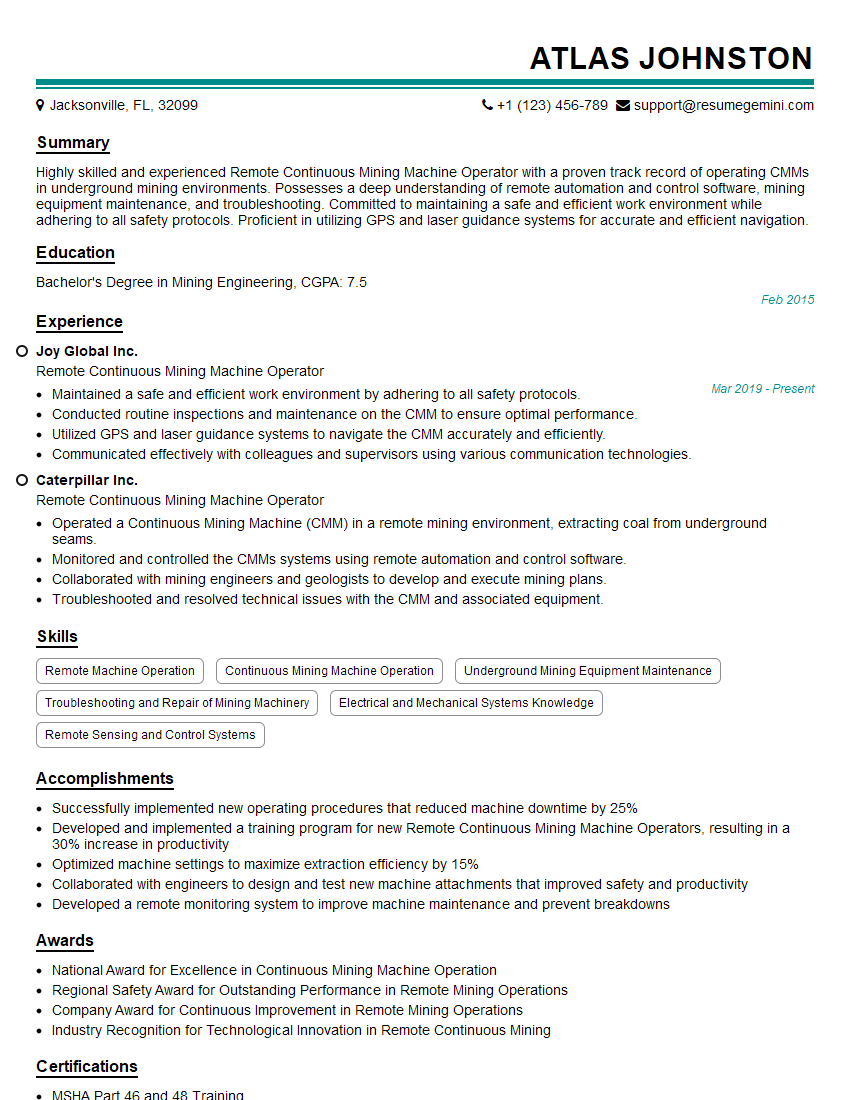

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Remote Continuous Mining Machine Operator

1. How do you ensure the stability and accuracy of the mining machine?

To ensure stability and accuracy, I employ various techniques. Firstly, I diligently monitor the machine’s sensors to detect any anomalies or deviations from optimal parameters. By analyzing these data, I can promptly identify potential issues and take corrective actions. Furthermore, I regularly calibrate and maintain the machine’s systems to maintain their precision and prevent drift.

2. Describe your process for monitoring and maintaining the health of the cutting bits.

Visual Inspection

- Regularly inspect the cutting bits for any signs of wear or damage.

- Use a magnifying glass to check for cracks or wear patterns.

Data Analysis

- Monitor the machine’s data logs to track the performance of the cutting bits.

- Identify any trends or anomalies that may indicate a need for maintenance.

3. How do you troubleshoot and resolve mechanical issues with the mining machine?

In the event of a mechanical issue, I follow a systematic troubleshooting process. I begin by identifying the symptoms and isolating the potential cause. I then consult technical manuals and diagrams to understand the affected systems and their interdependencies. Using diagnostic tools and my knowledge of the machine, I conduct tests to confirm the root cause. Once the issue is identified, I determine the appropriate repair or replacement parts and proceed with the necessary actions. I prioritize safety throughout the process.

4. How do you optimize the mining process to improve efficiency and safety?

To optimize the mining process, I leverage data analysis and continuous improvement techniques. I analyze operational data to identify areas for improvement, such as optimizing cutting patterns or adjusting machine parameters. By making informed adjustments, I enhance productivity while maintaining safety standards. Additionally, I participate in regular training and collaboration with engineers and other operators to stay abreast of best practices and implement innovative solutions.

5. How do you manage and communicate effectively with the remote team and supervisors?

Effective communication and teamwork are crucial for remote operations. I utilize real-time communication tools, such as video conferencing and instant messaging, to stay connected with the team and supervisors. I provide regular updates, share relevant data, and actively participate in discussions and decision-making. Additionally, I document and maintain clear records of all communication and actions taken to ensure transparency and accountability.

6. How do you maintain situational awareness while operating the mining machine remotely?

Maintaining situational awareness is critical for safe and efficient operation. I rely on multiple sensors and cameras to provide me with a comprehensive view of the mining environment. I monitor these inputs diligently, paying attention to potential hazards, obstacles, and changing conditions. Additionally, I utilize data visualization tools to interpret and analyze the machine’s performance and surroundings, which helps me make informed decisions and respond promptly to any unexpected events.

7. How do you handle emergencies and unplanned downtime while operating the mining machine remotely?

In the event of an emergency or unplanned downtime, I remain calm and follow established protocols. I immediately assess the situation, prioritize safety, and communicate the issue to the remote team and supervisors. I leverage diagnostic tools and my knowledge of the machine to troubleshoot and resolve any technical problems remotely. If necessary, I coordinate with on-site personnel to provide assistance or facilitate repairs. By responding swiftly and efficiently, I minimize downtime and ensure a safe and timely resumption of operations.

8. How do you stay updated on the latest advancements in mining technology and best practices?

To stay current with advancements in mining technology and best practices, I actively engage in continuous learning and professional development. I attend industry conferences, webinars, and training programs to gain knowledge about new technologies, techniques, and safety standards. Additionally, I regularly review technical publications, research papers, and industry news to stay informed about innovations and emerging trends. By staying up-to-date, I can incorporate the latest developments into my work, improve my skills, and contribute to the overall efficiency and safety of the mining operation.

9. How do you prioritize safety while operating a mining machine remotely?

Safety is my top priority when operating a mining machine remotely. I strictly adhere to established safety protocols and guidelines. I conduct thorough pre-operational checks to ensure the machine is in good working order. During operation, I maintain a high level of situational awareness, constantly monitoring the machine’s performance and the surrounding environment. I am vigilant in identifying potential hazards and taking appropriate actions to mitigate risks. By prioritizing safety, I not only protect myself but also contribute to the well-being of my team and the overall success of the mining operation.

10. How do you manage the challenges of operating a mining machine in remote locations with limited resources?

Operating a mining machine in remote locations with limited resources requires adaptability and resourcefulness. I leverage technology to the fullest extent possible, utilizing remote monitoring systems and diagnostic tools to troubleshoot and resolve issues efficiently. I am also skilled in improvisation and problem-solving, finding creative solutions to challenges using the available resources. Additionally, I proactively anticipate potential issues and take preventive measures to minimize downtime. By embracing the unique challenges of remote mining operations, I ensure the smooth and effective execution of tasks, contributing to the overall productivity and safety of the site.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Remote Continuous Mining Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Remote Continuous Mining Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Remote Continuous Mining Machine Operator is entrusted with the task of remotely operating a continuous mining machine to extract and convey minerals in an underground mining environment. This critical role demands a high level of technical expertise and vigilance to ensure efficient and safe mining operations.

1. Pre-Operational Procedures

To initiate the mining process smoothly, operators must thoroughly inspect the continuous mining machine, ensuring its components are in optimal working condition. They meticulously review maintenance records, identify any potential issues, and proactively address them to prevent breakdowns and maintain peak performance.

2. Machine Operation

With precision and dexterity, operators skillfully maneuver the continuous mining machine through the mine, utilizing its cutting head to extract minerals efficiently. They monitor various parameters such as cutting depth, speed, and conveyor functionality to optimize extraction rates while adhering to safety protocols.

3. Material Handling

Once the minerals are extracted, the operator deftly controls the continuous miner’s conveyor system to transport the material to designated loading points. They ensure a steady and uninterrupted flow of minerals, coordinating with other team members to maximize productivity and minimize downtime.

4. Monitoring and Troubleshooting

Operators vigilantly monitor the continuous mining machine’s performance through advanced sensors and displays. They swiftly diagnose any technical issues and take prompt corrective actions to restore optimal functionality. Their ability to quickly identify and resolve problems minimizes disruptions and enhances overall productivity.

Interview Tips

Interview Preparation for Remote Continuous Mining Machine Operator demands thorough research, practice, and a confident mindset. Here are some crucial tips to help candidates excel in the interview and showcase their capabilities.

1. Research the Industry and Company

Delve into the mining industry’s latest trends, technologies, and best practices to demonstrate your knowledge and understanding. Research the company’s history, values, and specific mining operations to tailor your answers to their needs.

2. Highlight Relevant Experience

Articulate your hands-on experience operating continuous mining machines or similar heavy equipment. Quantify your accomplishments and emphasize the impact of your contributions in previous roles, using specific metrics whenever possible.

3. Emphasize Safety and Problem-Solving Skills

Mining is an inherently hazardous industry, so employers prioritize candidates with a strong commitment to safety. Highlight your safety practices, adherence to regulations, and proactive approach to risk management. Additionally, showcase your problem-solving abilities, providing examples of how you effectively diagnosed and resolved technical issues.

4. Practice Commonly Asked Questions

Prepare for common interview questions related to your experience, skills, and knowledge of the mining industry. Practice answering these questions concisely and confidently, using the STAR method (Situation, Task, Action, Result) to provide structured and impactful responses.

Next Step:

Now that you’re armed with the knowledge of Remote Continuous Mining Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Remote Continuous Mining Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini