Are you gearing up for a career in Renovator Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Renovator Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

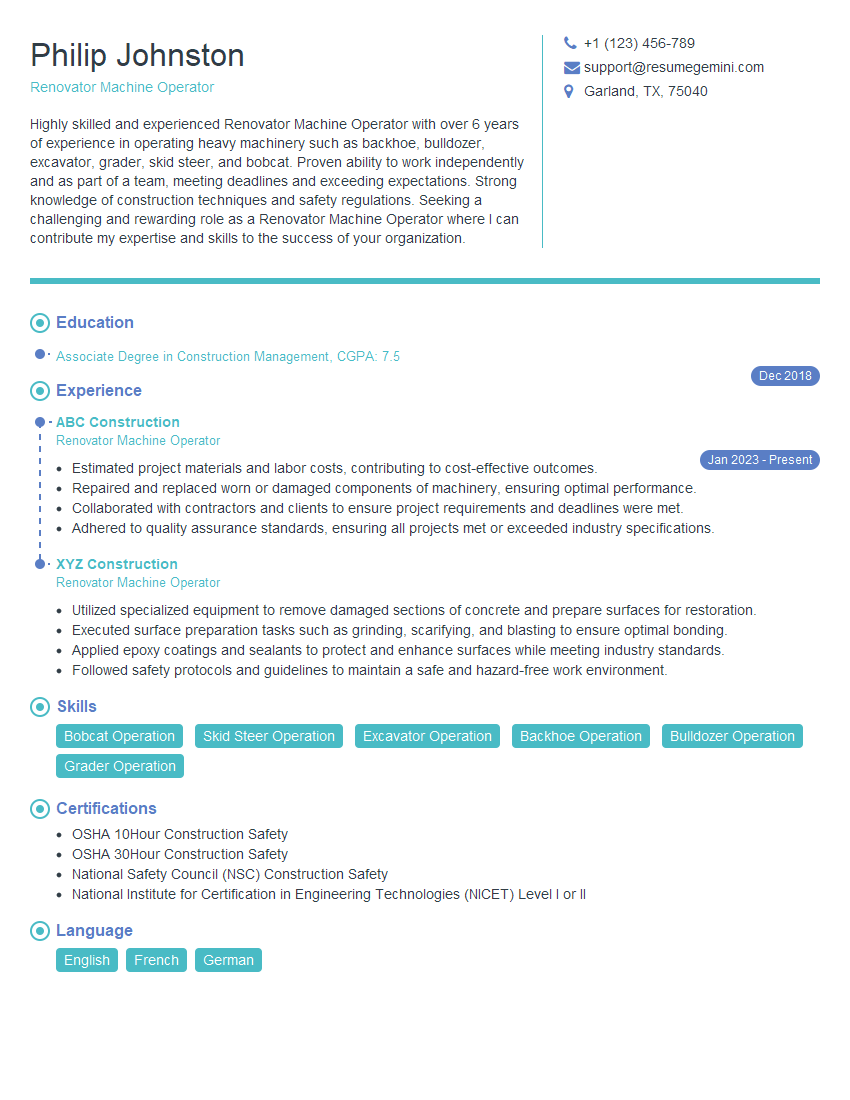

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Renovator Machine Operator

1. Which types of materials can you work with on the Renovator machine?

When working with the Renovator machine, I am experienced in handling various materials such as:

- Wood, including hardwoods and softwoods

- Plastic, ranging from rigid to flexible types

- Metals, including aluminum, brass, and steel

- Composite materials, like fiberglass and carbon fiber

- Stone and ceramic materials

2. How do you determine the appropriate cutting speed and feed rate for different materials?

Experience and Knowledge

- I rely on my experience and knowledge of the machine and different materials.

- I understand the characteristics and properties of each material, which helps me make informed decisions.

Manufacturer’s Guidelines

- I refer to the manufacturer’s recommendations and guidelines for suggested cutting speeds and feed rates.

- These guidelines provide a starting point and can be adjusted based on my experience and the specific application.

Testing and Optimization

- I conduct test cuts to determine the optimal settings for each material and cutting operation.

- This allows me to fine-tune the parameters for efficiency, precision, and surface finish.

3. What are the key safety precautions to observe when operating the Renovator machine?

- Wearing appropriate safety gear, including eye protection, hearing protection, gloves, and a dust mask

- Ensuring the machine is properly grounded and all electrical connections are secure

- Inspecting the machine before each use to identify any potential hazards or damage

- Keeping the work area clean and free of debris

- Following the manufacturer’s instructions and adhering to established safety protocols

- Never operating the machine under the influence of drugs or alcohol

4. How do you maintain and troubleshoot the Renovator machine?

Daily Maintenance

- Cleaning the machine, including removing debris and dust from the work surface, spindle, and other components

- Lubricating moving parts according to the manufacturer’s recommendations

- Inspecting belts, pulleys, and other mechanical components for wear or damage

Troubleshooting

- Identifying common issues and their potential causes through experience and troubleshooting guides

- Using diagnostic tools to pinpoint specific problems, such as electrical testers or pressure gauges

- Referring to the manufacturer’s documentation for guidance on resolving specific issues

- Contacting the manufacturer or a qualified technician for assistance with complex repairs or issues

5. What techniques do you use to achieve high-quality, precise cuts with the Renovator machine?

- Utilizing sharp and appropriate cutting tools for the material and operation

- Securing the workpiece firmly to prevent movement or vibration

- Operating the machine at the correct speed and feed rate to minimize chatter and ensure a smooth cut

- Paying attention to tool alignment and workpiece orientation for accurate cuts

- Using jigs and fixtures to guide the cutting process and ensure repeatability

6. How do you handle complex cutting operations, such as contour cutting or angled cuts, on the Renovator machine?

- Utilizing specialized attachments or jigs to facilitate contour cutting and angled cuts

- Creating templates or patterns to guide the cutting process and ensure accuracy

- Employing computer-aided design (CAD) software to generate cutting paths for complex operations

- Working with the machine’s software to program and control the cutting process for precision and efficiency

7. How do you stay updated on the latest advancements and best practices in Renovator machine operation?

- Attending industry conferences and workshops to learn from experts and peers

- Reading technical journals and publications to stay abreast of new technologies and techniques

- Consulting with the manufacturer for training and support on new features or capabilities

- Engaging in online forums and discussion groups to connect with other Renovator machine operators and share knowledge

8. What strategies do you employ to minimize waste and optimize material usage when operating the Renovator machine?

- Planning cutting paths to maximize material utilization and minimize scrap

- Utilizing nesting software to optimize part placement and reduce waste

- Recycling and reusing scrap material whenever possible

- Exploring alternative materials or processes that generate less waste

9. How do you ensure the quality and accuracy of finished products created with the Renovator machine?

- Inspecting raw materials to identify any defects or inconsistencies

- Calibrating the machine regularly to maintain precision and accuracy

- Utilizing measuring tools and gauges to verify dimensions and tolerances

- Performing test cuts to optimize cutting parameters and ensure desired results

- Implementing quality control processes to monitor and improve the production process

10. What types of industries and applications have you used the Renovator machine for in your previous experience?

I have applied my skills in the following industries and applications using the Renovator machine:

- Automotive industry: Creating prototypes and custom parts

- Aerospace industry: Manufacturing lightweight and high-precision components

- Medical industry: Producing devices and implants with intricate designs

- Consumer electronics industry: Fabricating casings and enclosures

- Defense industry: Developing specialized equipment and components

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Renovator Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Renovator Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Renovator Machine Operator is responsible for operating and maintaining specialized machinery used in the renovation and restoration of buildings and structures. Their primary duties include:

1. Machine Operation

Operate a variety of renovator machines, including sanders, grinders, and polishers.

- Set up and adjust machines according to specifications.

- Monitor machine performance and make necessary adjustments.

2. Surface Preparation

Prepare surfaces for renovation by removing existing finishes, such as paint, varnish, or tile.

- Use appropriate tools and techniques to remove old finishes.

- Clean and prepare surfaces for new finishes.

3. Finishing Applications

Apply new finishes to surfaces, including paint, stain, or sealant.

- Mix and apply finishes according to manufacturer’s instructions.

- Ensure a smooth and professional-looking finish.

4. Maintenance and Safety

Maintain and service renovator machines to ensure optimal performance.

- Inspect machines regularly for wear and tear.

- Perform routine maintenance and repairs as needed.

Interview Tips

To ace an interview for a Renovator Machine Operator position, follow these tips:

1. Research the Company and Role

Before the interview, take the time to research the company and the specific role you’re applying for. This will help you understand the company’s culture, mission, and the expectations for the position.

- Visit the company’s website and social media pages.

- Read online reviews and articles about the company.

2. Highlight Relevant Skills and Experience

In your resume and during the interview, emphasize the skills and experience that are most relevant to the Renovator Machine Operator role. These may include:

- Experience operating renovator machines, such as sanders, grinders, and polishers.

- Knowledge of surface preparation techniques.

- Experience applying finishes, such as paint, stain, or sealant.

3. Prepare for Common Interview Questions

There are several common interview questions that you can expect to be asked in an interview for a Renovator Machine Operator position. These questions may include:

- “Tell me about your experience operating renovator machines.”

- “What are some of the challenges you’ve faced in your previous role as a Renovator Machine Operator?”

- “How do you ensure a smooth and professional-looking finish?”

4. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Be respectful of the interviewers and ask thoughtful questions about the company and the role. This will show that you’re genuinely interested in the position and that you’re committed to performing well.

- Dress professionally for the interview.

- Arrive on time and be prepared to answer questions.

Next Step:

Now that you’re armed with the knowledge of Renovator Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Renovator Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini