Feeling lost in a sea of interview questions? Landed that dream interview for Repair Miller but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Repair Miller interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

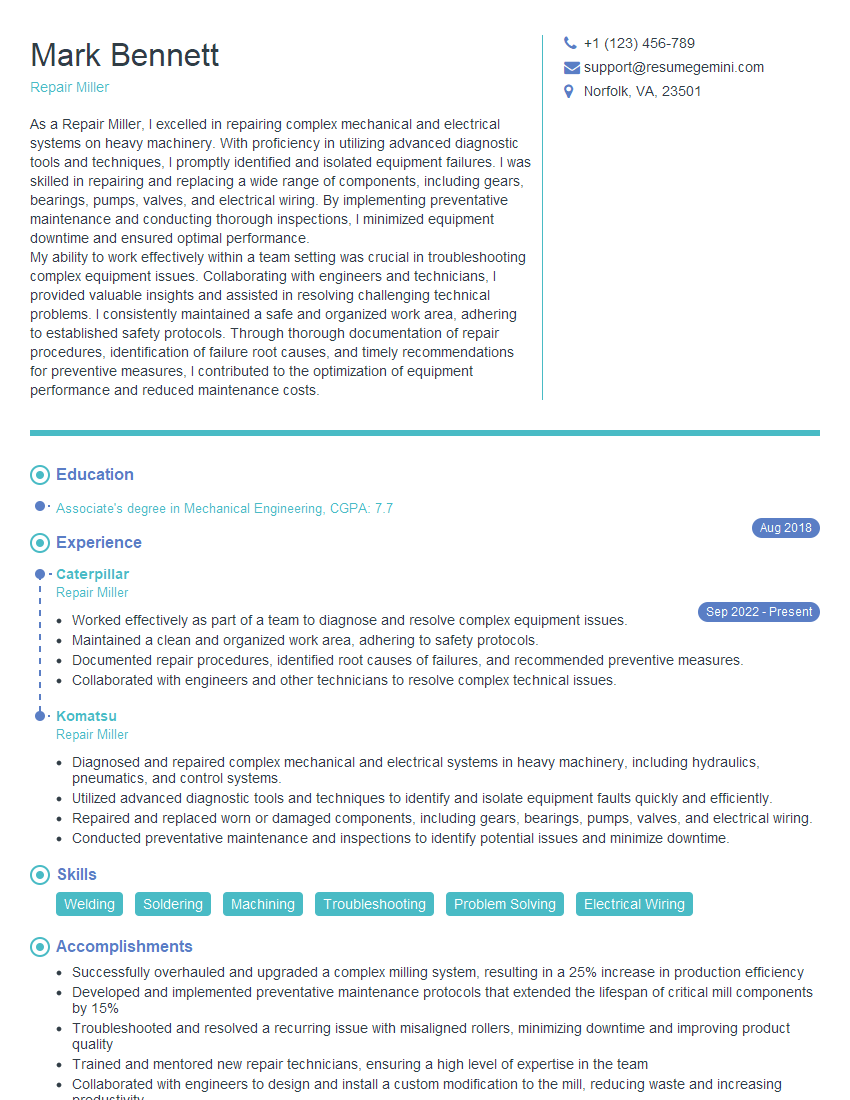

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Repair Miller

1. Describe the steps involved in troubleshooting an electrical motor overheating issue?

- Verify the voltage and current draw of the motor using a multimeter.

- Check for proper cooling and ventilation around the motor.

- Inspect the motor bearings for any signs of wear or contamination.

- Examine the motor windings for any insulation damage or shorts.

- Test the motor’s insulation resistance using an insulation tester.

2. How do you handle situations where you are unable to diagnose or repair an issue?

Escalation Plan

- Consult with a senior technician or supervisor for guidance.

- Refer the issue to a specialized repair facility if necessary.

Communication

- Inform the customer clearly about the issue and the steps taken to resolve it.

- Document the issue and the actions taken for future reference.

3. What are the safety precautions you take when working with electrical equipment?

- Wear appropriate personal protective equipment (PPE), including insulated gloves and safety glasses.

- Verify the electrical isolation of the equipment before touching it.

- Use proper grounding and bonding techniques to prevent electrical shocks.

- Follow lockout/tagout procedures to prevent accidental energization.

- Be aware of the location of emergency stop buttons and circuit breakers.

4. Describe the process of replacing a capacitor in an electrical system.

- Discharge the capacitor completely using a resistor or capacitor discharger.

- Disconnect the capacitor from the circuit.

- Replace the capacitor with one of the same capacitance and voltage rating.

- Reconnect the capacitor to the circuit.

- Test the circuit to ensure proper operation.

5. How do you test the continuity of a circuit?

- Use a multimeter set to the continuity setting.

- Connect the multimeter leads to the two points in the circuit to be tested.

- The multimeter will indicate continuity if a complete circuit is present.

6. What are the different types of electrical wiring used in industrial settings?

- Conduit: Rigid metal or plastic pipes that protect wires and cables.

- Cable trays: Metal or plastic trays that support and organize multiple cables.

- Raceways: Enclosed channels that run along walls or ceilings for wire distribution.

- Busways: Enclosed metal ducts that distribute power to multiple outlets.

7. How do you determine the root cause of a electrical failure?

- Gather information about the circumstances leading to the failure.

- Inspect the equipment and wiring for any visible damage or defects.

- Perform electrical tests to identify any shorts, opens, or overloads.

- Review maintenance records and operating logs for any indications of previous issues.

- Consult with equipment manufacturers or other experts for further guidance.

8. What software or tools do you use for electrical troubleshooting and repair?

- Multimeters: Measure voltage, current, and resistance.

- Insulation testers: Test the insulation resistance of electrical components.

- Clamp meters: Measure current without breaking the circuit.

- Power quality analyzers: Monitor electrical waveform characteristics.

- Electrical safety software: Assist with hazard analysis and risk assessment.

9. How do you stay updated on the latest electrical codes and standards?

- Attend industry conferences and seminars.

- Read trade publications and technical manuals.

- Participate in online forums and discussion groups.

- Obtain certifications and licenses that require up-to-date knowledge.

10. Describe a challenging electrical repair you have successfully completed.

Problem

Troubleshooting

Solution

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Repair Miller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Repair Miller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Repair Millers are responsible for repairing and maintaining a variety of equipment and machinery in industrial settings. They use their skills and knowledge to diagnose problems, make repairs, and ensure that equipment is operating safely and efficiently.

1. Troubleshooting and diagnosing mechanical problems

Repair Millers are often the first line of defense when equipment breaks down. They must be able to quickly and accurately diagnose the problem so that they can make the necessary repairs.

- Identify and assess mechanical problems with industrial machinery and equipment

- Perform diagnostic tests and inspections to determine the cause of malfunctions

2. Repairing and replacing damaged parts

Once the problem has been diagnosed, Repair Millers must be able to repair or replace the damaged parts. This may involve using hand tools, power tools, and other specialized equipment.

- Repair or replace worn or damaged parts using hand tools, power tools, and equipment

- Recondition and rebuild components to restore optimal performance and extend equipment lifespan

3. Installing and setting up new equipment

In addition to repairing existing equipment, Repair Millers may also be responsible for installing and setting up new equipment. This involves ensuring that the equipment is properly assembled, calibrated, and tested.

- Install, assemble, and commission new equipment according to specifications

- Ensure alignment, lubrication, and adjustment of machinery for optimal performance

4. Maintaining and inspecting equipment

Regular maintenance is essential to prevent equipment from breaking down. Repair Millers are responsible for performing routine maintenance tasks, such as lubrication, cleaning, and inspection.

- Lubricate, clean, and inspect machinery to prevent breakdowns and extend lifespan

- Maintain records and document maintenance activities for compliance and future reference

Interview Tips

To ace your interview for a Repair Miller position, you should:

1. Research the company and the position

This will help you understand the company’s culture and the specific requirements of the position.

- Visit the company’s website and social media pages

- Read industry news and articles to stay up-to-date on trends

2. Practice your answers to common interview questions

This will help you feel confident and prepared during the interview.

- Can you tell me about your experience repairing industrial machinery?

- What are your strengths and weaknesses as a Repair Miller?

- What is your approach to troubleshooting mechanical problems?

3. Be prepared to talk about your safety experience

Safety is paramount in industrial settings.

- Highlight your knowledge of safety regulations and procedures

- Share examples of how you have maintained a safe work environment in previous roles

4. Dress appropriately and arrive on time

First impressions matter, so make sure you dress professionally and arrive on time for your interview.

- Wear clean, pressed clothing that is appropriate for an industrial setting

- Arrive 10-15 minutes early for your interview

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Repair Miller, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Repair Miller positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.