Are you gearing up for a career in Reprographics Technician? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Reprographics Technician and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

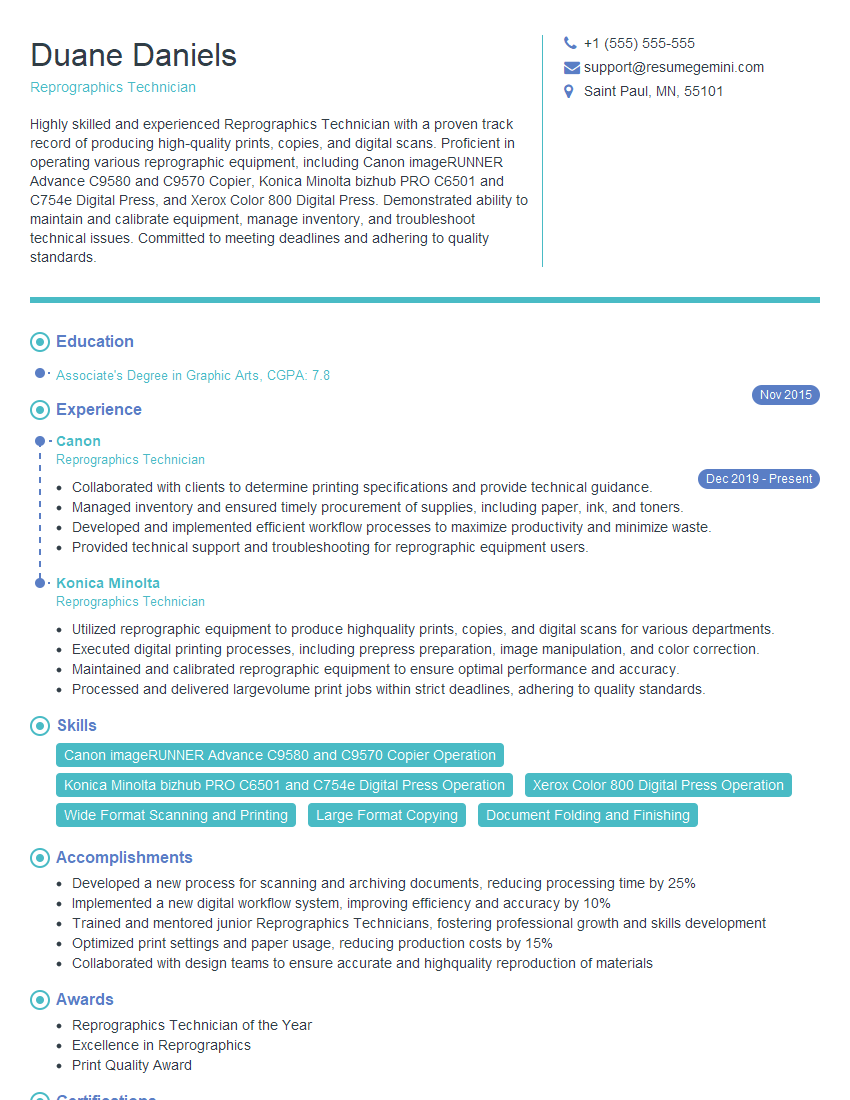

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reprographics Technician

1. Describe the process of preparing a digital file for offset printing?

The process of preparing a digital file for offset printing involves several key steps:

- Create a high-resolution digital file: The file should be created in a program that supports CMYK color mode and a resolution of at least 300dpi.

- Convert the file to a PDF format: PDF is the preferred file format for offset printing, as it preserves the layout and colors accurately.

- Check the file for errors: Use prepress software to check the file for any errors, such as missing fonts, low-resolution images, or incorrect colors.

- Output the file to plates: The PDF file is then output to printing plates, which are used to transfer the image to paper.

2. What are the different types of printing presses used in reprographics?

The main types of printing presses used in reprographics are:

- Offset printing press: This is the most common type of printing press, which uses a series of rollers to transfer the image from a plate to paper.

- Digital printing press: This type of press uses digital technology to directly print the image onto paper, without the need for plates.

- Flexographic printing press: This press is used for printing on flexible materials, such as plastic films and packaging.

- Gravure printing press: This press uses a cylinder with etched images to transfer the ink to paper.

3. What are the different types of paper used in reprographics?

The most common types of paper used in reprographics are:

- Bond paper: This is a lightweight, inexpensive paper that is commonly used for everyday printing.

- Offset paper: This is a high-quality paper that is used for offset printing.

- Coated paper: This paper has a special coating that makes it glossy and resistant to fading.

- specialty papers: These papers have unique properties, such as being waterproof or fire-resistant.

4. What are the different types of binding used in reprographics?

The main types of binding used in reprographics are:

- Saddle stitching: This is a simple and inexpensive binding method that involves stapling the pages together at the spine.

- Perfect binding: This binding method uses glue to adhere the pages together at the spine, creating a more durable and professional-looking finish.

- Spiral binding: This binding method uses a plastic or metal coil to bind the pages together, allowing the book to lay flat.

- Hard binding: This binding method uses a hard cover to protect the pages, making it suitable for books that will receive heavy use.

5. What are the different types of finishing services offered in reprographics?

Common finishing services offered in reprographics include:

- Cutting: Cutting the printed materials to the desired size and shape.

- Folding: Folding the printed materials to create brochures or other folded items.

- Collating: Gathering and assembling the printed materials in the correct order.

- Laminating: Applying a protective layer of plastic to the printed materials to make them more durable.

- Embossing: Creating raised lettering or designs on the printed materials.

- Die-cutting: Using a die to cut custom shapes out of the printed materials.

6. How do you ensure the quality of your reprographics work?

- Using high-quality materials and equipment: Investing in top-notch materials and equipment helps ensure that the finished product will be of the highest quality.

- Following industry standards: Adhering to industry standards for color management, paper selection, and binding ensures that the work meets professional expectations.

- Implementing quality control measures: Establishing a rigorous quality control process involves checking the work at each stage of the production process to identify and correct any errors.

- Seeking feedback from customers: Regularly gathering feedback from customers allows you to identify areas for improvement and ensure that their needs are being met.

7. What is your experience with digital printing technologies?

Throughout my career, I have gained extensive experience with various digital printing technologies, including:

- High-volume production printers: Operating high-volume production printers to produce large quantities of high-quality prints efficiently.

- Wide-format printers: Utilizing wide-format printers to create large-scale prints, such as posters, banners, and trade show displays.

- 3D printers: Proficient in operating 3D printers to produce three-dimensional objects for prototyping and manufacturing.

- Digital presses: Experienced in operating digital presses to produce short-run, on-demand printing projects with precise color reproduction.

8. How do you stay up-to-date with the latest reprographics technologies?

- Attending industry events: Regularly participating in industry conferences, trade shows, and workshops to learn about the latest advancements in reprographics technologies.

- Reading industry publications: Subscribing to relevant industry publications and online resources to stay informed about new technologies, trends, and best practices.

- Networking with industry professionals: Connecting with other reprographics professionals through online forums, social media, and professional organizations to exchange knowledge and ideas.

- Seeking professional development opportunities: Pursuing professional development courses, certifications, and workshops to enhance my skills and knowledge in the field.

9. What are some of the challenges you have faced in your reprographics work and how did you overcome them?

Throughout my reprographics career, I have encountered several challenges, including:

- Meeting tight deadlines: To overcome tight deadlines, I prioritize tasks effectively, allocate resources efficiently, and communicate regularly with clients to manage their expectations.

- Ensuring color accuracy: To achieve accurate color reproduction, I utilize calibrated monitors, color management software, and work closely with clients to understand their specific color requirements.

- Handling complex printing projects: For complex printing projects, I conduct thorough planning, research different printing techniques, and collaborate with a team of experts to deliver high-quality results.

- Troubleshooting printing issues: When encountering printing issues, I systematically identify the root cause, consult technical documentation, and apply troubleshooting techniques to resolve the problem efficiently.

10. Why are you interested in working as a Reprographics Technician for our company?

I am eager to join your esteemed company as a Reprographics Technician because I am highly motivated and passionate about the field of reprographics. With my proven expertise in digital printing technologies, attention to detail, and commitment to delivering exceptional results, I am confident in my ability to make a significant contribution to your team.

I am particularly drawn to your company’s reputation for producing high-quality reprographics work and its commitment to customer satisfaction. I am eager to leverage my skills and experience to support your operations and contribute to the success of your clients’ projects.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reprographics Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reprographics Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Reprographics Technicians are responsible for the operation, maintenance, and repair of reprographics equipment, such as copiers, printers, scanners, and plotters. They also provide technical support to users and troubleshoot problems.

1. Operate and maintain reprographics equipment

Reprographics Technicians are responsible for the day-to-day operation and maintenance of reprographics equipment. This includes loading paper, toner, and other supplies; cleaning and calibrating equipment; and performing routine maintenance.

- Load paper, toner, and other supplies

- Clean and calibrate equipment

- Perform routine maintenance

2. Troubleshoot problems

Reprographics Technicians are also responsible for troubleshooting problems with reprographics equipment. This includes diagnosing the problem, determining the cause, and taking steps to resolve the issue.

- Diagnose the problem

- Determine the cause

- Take steps to resolve the issue

3. Provide technical support to users

Reprographics Technicians provide technical support to users of reprographics equipment. This includes answering questions, providing training, and helping users to resolve problems.

- Answer questions

- Provide training

- Help users to resolve problems

4. Maintain inventory

Reprographics Technicians are also responsible for maintaining inventory of supplies, such as paper, toner, and ink. This includes ordering supplies, tracking inventory levels, and ensuring that supplies are available when needed.

- Order supplies

- Track inventory levels

- Ensure that supplies are available when needed

Interview Tips

To ace an interview for a Reprographics Technician position, it is important to be prepared and to have a clear understanding of the key job responsibilities. Here are a few tips to help you prepare for your interview:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, in their annual report, and in articles about the company in the news.

- Visit the company’s website

- Read the company’s annual report

- Read articles about the company in the news

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions ahead of time so that you can deliver your answers confidently and clearly.

- Tell me about yourself

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

- Do you have any questions for me?

3. Prepare questions to ask the interviewer

Asking the interviewer questions is a great way to show that you are interested in the position and that you are taking the interview seriously. It is also a good way to get more information about the company and the position.

- What are the biggest challenges facing the company right now?

- What are the company’s goals for the next year?

- What is the company culture like?

- What are the opportunities for advancement?

- Is there anything else I can provide you with today?

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you are taking the interview seriously.

- Dress professionally

- Arrive on time

5. Be yourself and be confident

The most important thing is to be yourself and to be confident in your abilities. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just be yourself and let your personality shine through.

- Be yourself

- Be confident

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Reprographics Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!