Feeling lost in a sea of interview questions? Landed that dream interview for Resaw Carriage Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Resaw Carriage Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

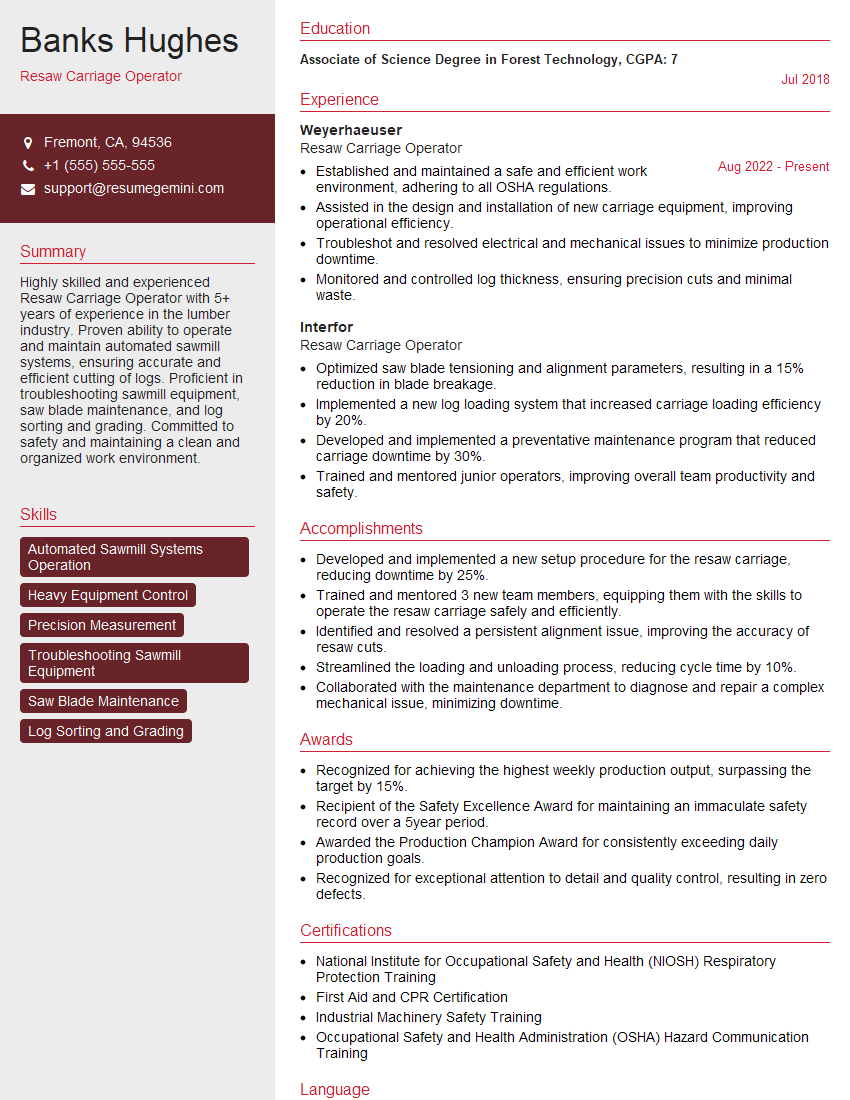

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Resaw Carriage Operator

1. Explain the process of setting up and operating a resaw carriage.

Setting up a resaw carriage requires the following steps:

- Mount the resaw carriage on the saw bench.

- Check that the carriage is level and square to the saw blade.

- Set the fence to the desired width of the cut.

- Attach the workpiece to the carriage.

Operating a resaw carriage involves feeding the workpiece into the saw blade while maintaining a steady pressure on the carriage. The operator must also ensure that the workpiece is kept square to the saw blade. This requires close attention to the workpiece as it is being cut.

2. What are the safety precautions that must be taken when operating a resaw carriage?

Safe setup

- Ensure the resaw carriage is securely mounted on the saw bench.

- Check that the carriage is level and square to the saw blade.

- Make sure the fence is set to the desired width of the cut.

- Inspect the workpiece for any defects or knots that could cause the workpiece to bind or kickback.

Safe operation

- Wear appropriate safety gear, including eye protection, hearing protection, and gloves.

- Feed the workpiece into the saw blade slowly and steadily.

- Maintain a firm grip on the carriage and keep the workpiece square to the saw blade.

- Be aware of the location of your hands and fingers in relation to the saw blade.

3. What are the different types of blades that can be used on a resaw carriage?

There are several types of blades that can be used on a resaw carriage, including:

- Flat-ground blades are the most common type of blade used for resawing. They have a flat profile and are available in a variety of widths and tooth configurations.

- Skip-tooth blades have teeth that are spaced apart, which reduces the amount of friction between the blade and the workpiece. This makes them ideal for cutting hardwoods and other difficult-to-cut materials.

- Band saw blades are continuous loops of steel that are used for cutting curves and irregular shapes. They are available in a variety of widths and tooth configurations.

4. How do you determine the correct blade tension for a resaw carriage?

The correct blade tension for a resaw carriage depends on the type of blade being used and the thickness of the workpiece. As a general rule of thumb, the blade should be tensioned so that it deflects about 1/16 inch when pressed in the center. This can be checked using a blade tension gauge.

5. What are the common problems that can occur when operating a resaw carriage?

Some common problems that can occur when operating a resaw carriage include:

- Blade wander: This occurs when the blade moves side to side as it cuts, which can cause the workpiece to be cut unevenly. Blade wander can be caused by a number of factors, including improper blade tension, a dull blade, or a warped workpiece.

- Pinch: This occurs when the workpiece is pinched between the blade and the fence, which can cause the workpiece to be damaged or the blade to break.

- Kickback: This occurs when the workpiece is suddenly thrown back at the operator, which can be very dangerous. Kickback can be caused by a number of factors, including improper workpiece handling, a dull blade, or a workpiece that is too thin.

6. How do you troubleshoot and fix a resaw carriage that is not operating properly?

If a resaw carriage is not operating properly, there are a few things that you can do to troubleshoot the problem:

- Check the blade tension: Make sure that the blade is tensioned correctly. If the blade is too loose, it will wander and cut unevenly. If the blade is too tight, it will be difficult to feed the workpiece through the saw.

- Check the blade for sharpness: A dull blade will cause the workpiece to be cut unevenly and can lead to kickback. If the blade is dull, it should be sharpened or replaced.

- Check the workpiece for defects: Make sure that the workpiece is free of any defects or knots that could cause the workpiece to bind or kickback.

- Check the fence for alignment: Make sure that the fence is aligned correctly with the saw blade. If the fence is not aligned, the workpiece will be cut unevenly.

7. What are the maintenance tasks that should be performed on a resaw carriage?

Regular maintenance is important to keep a resaw carriage operating properly and safely. Some of the maintenance tasks that should be performed on a resaw carriage include:

- Cleaning: The carriage should be cleaned regularly to remove sawdust and other debris. This will help to prevent the carriage from binding or jamming.

- Lubrication: The carriage should be lubricated regularly to reduce friction and wear. This will help to extend the life of the carriage and its components.

- Blade inspection: The blade should be inspected regularly for signs of wear or damage. If the blade is damaged, it should be replaced immediately.

- Fence alignment: The fence should be checked for alignment regularly. If the fence is not aligned, it should be adjusted.

8. What are the different types of wood that can be resawn?

A resaw carriage can be used to resaw a variety of different types of wood, including:

- Hardwoods: Hardwoods are denser and more difficult to cut than softwoods. Some common hardwoods that can be resawn include oak, maple, cherry, and walnut.

- Softwoods: Softwoods are less dense and easier to cut than hardwoods. Some common softwoods that can be resawn include pine, fir, spruce, and cedar.

- Exotic woods: Exotic woods are often more expensive and difficult to find than domestic woods. Some common exotic woods that can be resawn include mahogany, teak, and rosewood.

9. What are the different thicknesses that can be resawn?

The thickness of the wood that can be resawn depends on the size of the resaw carriage and the type of blade being used. Most resaw carriages can handle wood up to 12 inches thick. However, some larger carriages can handle wood up to 24 inches thick.

10. What are the advantages of using a resaw carriage?

There are several advantages to using a resaw carriage, including:

- Accuracy: A resaw carriage allows you to cut wood more accurately than you can with a handheld saw.

- Safety: A resaw carriage is a much safer way to cut wood than a handheld saw. This is because the carriage holds the wood in place, which prevents it from moving around and coming into contact with the blade.

- Efficiency: A resaw carriage can help you to cut wood more quickly and efficiently than you can with a handheld saw.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Resaw Carriage Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Resaw Carriage Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Resaw Carriage Operator is responsible for the safe and efficient operation of a resaw carriage system, which cuts lumber into smaller pieces. Some key job responsibilities and duties include:

1. Carriage Operation:

- Operate the resaw carriage system to cut lumber into smaller pieces according to specified dimensions.

- Control the speed and feed rate of the carriage to ensure optimal cutting performance.

- Monitor the carriage for any malfunctions or irregularities and report them promptly.

2. Lumber Handling:

- Position lumber accurately on the carriage system for cutting.

- Remove cut lumber from the carriage and stack or bundle it for further processing.

- Check for defects or damage to lumber before and after cutting.

3. Equipment Monitoring and Maintenance:

- Perform routine inspections and maintenance on the resaw carriage system, including lubrication, adjustments, and cleaning.

- Identify and address minor equipment issues to prevent interruptions to production.

- Report any major equipment problems or repairs to supervisors.

4. Quality Control:

- Monitor the quality of cut lumber to ensure it meets specifications.

- Identify and reject any lumber with defects or irregularities.

- Implement quality control measures to improve the accuracy and consistency of cut pieces.

5. Safety Procedures:

- Adhere to all safety regulations and procedures related to the operation of the resaw carriage system.

- Wear appropriate personal protective equipment (PPE) while operating the equipment.

- Maintain a clean and organized work area to minimize safety risks.

Interview Tips

To help you ace your interview for a Resaw Carriage Operator role, consider the following tips:

1. Research the Company and Position:

- Learn about the company’s history, values, and products.

- Review the job description thoroughly to understand the specific requirements of the role.

- Prepare questions to ask the interviewer that demonstrate your interest and engagement.

2. Highlight Relevant Skills and Experience:

- Emphasize your experience in operating resaw carriage systems or similar equipment.

- Describe your knowledge of lumber cutting techniques and quality control procedures.

- Share examples of how you have maintained a safe and efficient work environment.

3. Practice Common Interview Questions:

- Prepare for questions about your work history, skills, and motivations.

- Practice answering behavioral questions using the STAR method (Situation, Task, Action, Result).

- Consider questions the interviewer may ask about your understanding of the resaw carriage system and its operation.

4. Dress Professionally and Arrive on Time:

- Dress appropriately for an industrial setting, as you may be asked to demonstrate your physical capabilities.

- Punctuality shows respect for the interviewer’s time.

5. Be Enthusiastic and Ask Questions:

- Show your interest in the role and the company.

- Ask thoughtful questions to clarify the job responsibilities and expectations.

- Express your enthusiasm for working in the lumber industry and sharing your expertise.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Resaw Carriage Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!