Are you gearing up for an interview for a Resaw Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Resaw Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

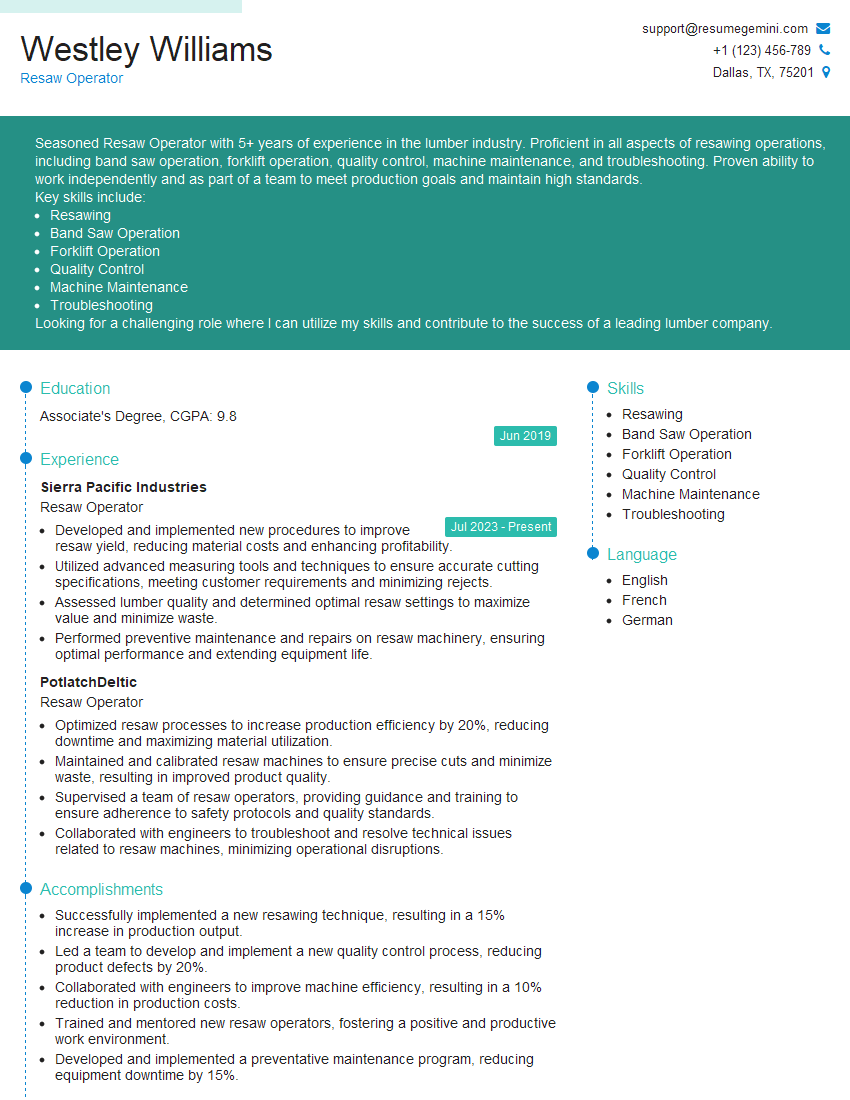

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Resaw Operator

1. Describe the process of operating a resaw machine.

- Prepare the machine by ensuring the saw blade is properly tensioned and aligned, and the guides are set to the appropriate width.

- Load the timber onto the infeed conveyor and align it against the fence.

- Start the machine and engage the saw blade.

- Guide the timber through the machine, applying steady pressure to ensure a smooth cut.

- Monitor the cut and make adjustments to the feed speed or saw blade tension as needed.

- Unload the resawn timber from the outfeed conveyor.

2. How do you determine the optimal blade size and type for a given cutting job?

Blade Size

- Consider the thickness and width of the timber to be cut.

- Select a blade with a diameter that allows for a minimum of two teeth to be engaged in the cut at all times.

Blade Type

- Choose a blade with the appropriate tooth geometry for the type of wood being cut, such as rip, crosscut, or combination.

- Consider the hardness and abrasiveness of the wood to determine the best blade material, such as carbide or steel.

3. What are the key factors that affect the quality of a resaw cut?

- Proper saw blade tension and alignment.

- Precisely set guides and fences.

- Appropriate feed speed and saw blade speed.

- Properly maintained equipment.

- Operator skill and experience.

4. Describe the different types of defects that can occur during resawing and how to prevent them.

- Wavy or uneven cuts: Caused by variations in the feed speed or pressure applied to the timber. Use a consistent feed speed and apply even pressure.

- Tear-out: Occurs when the saw blade grabs and tears the wood fibers. Use a sharp blade, ensure proper saw blade tension, and adjust the feed speed.

- Burn marks: Caused by excessive friction between the saw blade and the wood. Use a sharp blade, adjust the feed speed and saw blade speed, and cool the workpiece with lubricant.

- Misaligned cuts: Result from incorrectly set guides or fences. Ensure that the guides and fences are precisely aligned before starting the cut.

5. How do you troubleshoot common problemas with a resaw machine?

- Vibrations: Loose or unbalanced components, worn bearings, or a misaligned blade. Check and tighten all components, replace worn bearings, and ensure the blade is properly aligned.

- Excessive noise: Dull or damaged blade, worn bearings, or misaligned components. Replace the blade, replace worn bearings, and ensure proper alignment.

- Poor cut quality: Dull or misaligned blade, incorrect feed speed or saw blade speed, or worn guides. Replace the blade, adjust the feed speed and saw blade speed, and ensure that the guides are in good condition.

6. What safety precautions should be taken when operating a resaw machine?

- Wear appropriate safety gear, including eye protection, hearing protection, and gloves.

- Ensure that the machine is properly grounded and guarded.

- Never operate the machine under the influence of drugs or alcohol.

- Keep the work area clean and well-lit.

- Be aware of the location of the emergency stop button.

7. Describe the importance of regular maintenance for a resaw machine.

- Prevents costly breakdowns and downtime.

- Extends the lifespan of the machine.

- Ensures optimal performance and safety.

- Reduces the risk of accidents.

8. How do you perform routine maintenance on a resaw machine?

- Clean and inspect the machine regularly, removing any sawdust or debris.

- Check and adjust the saw blade tension and alignment.

- Inspect the guides and fences for wear or damage.

- Replace worn or damaged components as needed.

- Lubricate moving parts according to the manufacturer’s recommendations.

9. What are the different types of resaw machines?

- Horizontal resaws: Cut timber into boards or planks.

- Vertical resaws: Cut logs into boards or beams.

- Combination resaws: Can be used for both horizontal and vertical resawing.

10. How do you improve the efficiency of a resawing operation?

- Use sharp blades and maintain proper saw blade tension.

- Set guides and fences precisely and ensure they are in good condition.

- Adjust feed speed and saw blade speed for optimal cutting efficiency.

- Minimize downtime for blade changes and maintenance.

- Train operators to follow best practices and maximize productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Resaw Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Resaw Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Resaw Operators are responsible for managing a resaw machine, which cuts lumber into smaller pieces. They must be able to operate the machine safely and efficiently, as well as make adjustments to the machine as needed. Resaw Operators must also be able to identify and correct defects in the lumber.

1. Operate and maintain resaw machine

Resaw Operators are responsible for operating and maintaining the resaw machine. This includes setting up the machine, making adjustments to the machine, and troubleshooting any problems that may arise. Resaw Operators must also be able to identify and correct defects in the lumber.

- Set up the machine according to specifications.

- Make adjustments to the machine to ensure proper operation.

- Troubleshoot any problems that may arise.

- Identify and correct defects in the lumber.

2. Monitor and inspect lumber

Resaw Operators are responsible for monitoring and inspecting the lumber. This includes checking the lumber for defects, such as knots, splits, and cracks. Resaw Operators must also be able to identify and correct any defects that may be found.

- Check the lumber for defects.

- Identify and correct any defects that may be found.

- Remove any defective lumber from the production line.

- Report any defects to the supervisor.

3. Maintain a clean and safe work area

Resaw Operators are responsible for maintaining a clean and safe work area. This includes cleaning up any debris or waste, as well as ensuring that all equipment is in good working order. Resaw Operators must also be able to identify and correct any safety hazards that may arise.

- Clean up any debris or waste.

- Ensure that all equipment is in good working order.

- Identify and correct any safety hazards.

- Report any safety concerns to the supervisor.

4. Follow safety procedures

Resaw Operators must follow all safety procedures, including wearing personal protective equipment (PPE) and following lockout/tagout procedures. Resaw Operators must also be able to identify and correct any safety hazards that may arise.

- Wear personal protective equipment (PPE).

- Follow lockout/tagout procedures.

- Identify and correct any safety hazards.

- Report any safety concerns to the supervisor.

Interview Tips

Preparing for an interview can be daunting, but there are some things you can do to increase your chances of success. Here are a few tips:

1. Research the company and the position

Before you go into an interview, it’s important to do your research. This means learning about the company, the position you’re applying for, and the industry. This will help you answer questions intelligently and show that you’re genuinely interested in the job.

- Visit the company website.

- Read the job description.

- Research the industry.

- Talk to people who work in the industry.

2. Practice your answers to common interview questions

There are some common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions ahead of time so that you can deliver them confidently and succinctly.

- Prepare a brief introduction of yourself.

- Write down your answers to common interview questions.

- Practice your answers out loud.

- Get feedback from a friend or family member.

3. Dress professionally

First impressions matter, so it’s important to dress professionally for your interview. This doesn’t mean you have to wear a suit and tie, but you should dress in clean, pressed clothes that are appropriate for the workplace.

- Dress in clean, pressed clothes.

- Choose clothes that are appropriate for the workplace.

- Avoid wearing clothes that are too revealing or too casual.

- Make sure your shoes are clean and polished.

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you’re running late, call the interviewer to let them know. This will show that you’re respectful of their time.

- Plan your route to the interview in advance.

- Leave yourself plenty of time to get to the interview.

- If you’re running late, call the interviewer to let them know.

- Be prepared to explain why you were late.

5. Be yourself

The most important thing is to be yourself during your interview. Don’t try to be someone you’re not, because the interviewer will be able to tell. Just relax, be honest, and let your personality shine through.

- Be yourself.

- Don’t try to be someone you’re not.

- Relax and be honest.

- Let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Resaw Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!