Are you gearing up for a career in Research and Development Machinist? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Research and Development Machinist and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

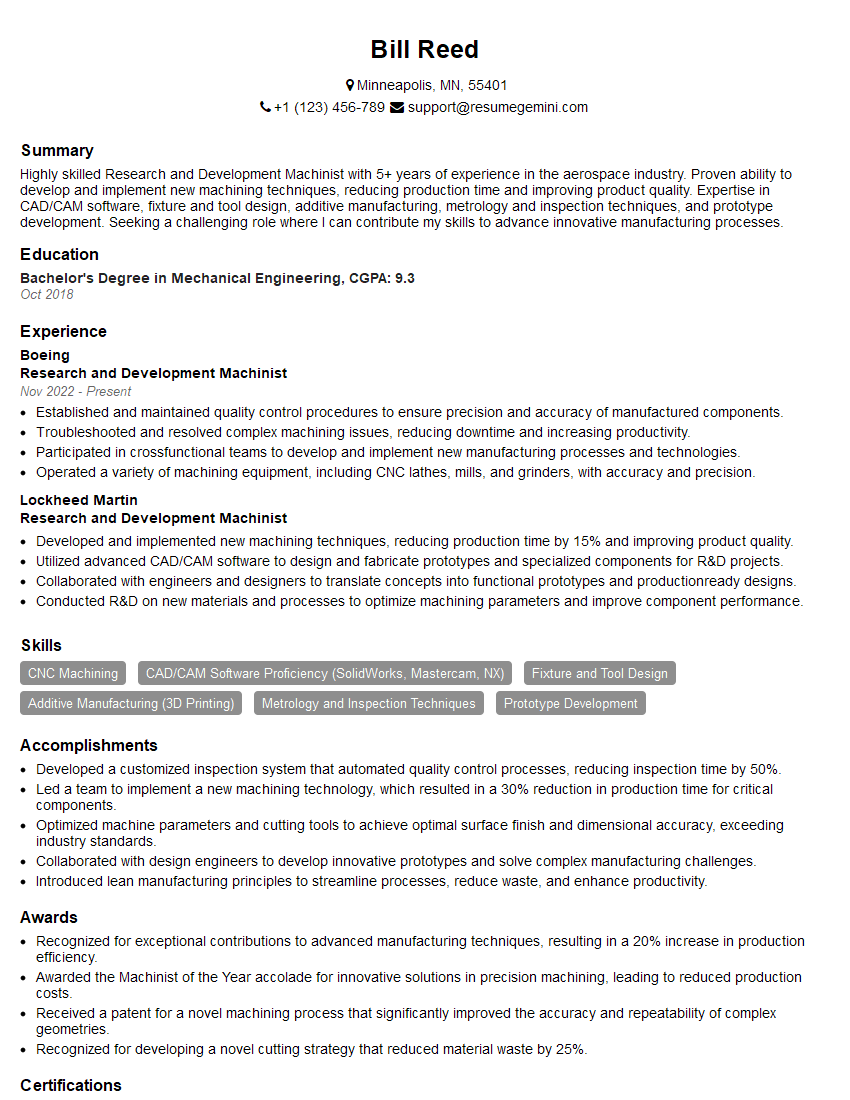

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Research and Development Machinist

1. What are the essential steps involved in the research and development process for a new machining process?

Answer:

- Define the problem or opportunity.

- Research existing technologies and processes.

- Develop a concept or prototype.

- Test and evaluate the concept or prototype.

- Refine and optimize the process.

- Implement the process into production.

2. Describe the different types of machining processes and their applications.

Answer:

subheading of the answer

- Turning: Used to create round or cylindrical parts from metal or plastic.

- Milling: Used to create flat or curved surfaces from metal or plastic.

- Drilling: Used to create holes in metal or plastic.

- Grinding: Used to finish machined surfaces.

- EDM: Used to create complex shapes in metal or plastic.

subheading of the answer

- Turning: Automotive, aerospace, medical

- Milling: Aerospace, automotive, medical

- Drilling: Construction, automotive, manufacturing

- Grinding: Automotive, aerospace, manufacturing

- EDM: Aerospace, medical, automotive

3. What are the key factors to consider when selecting a machining process for a particular application?

Answer:

- The type of material being machined.

- The desired accuracy and surface finish.

- The production volume.

- The cost of the process.

- The availability of skilled labor.

4. How do you stay up-to-date on the latest developments in machining technology?

Answer:

- Read industry publications.

- Attend industry trade shows and conferences.

- Network with other machining professionals.

- Take online courses and workshops.

- Experiment with new technologies in the shop.

5. What is your experience with using computer-aided design (CAD) and computer-aided manufacturing (CAM) software?

Answer:

- Proficient in using CAD software such as SolidWorks, AutoCAD, and Creo.

- Experienced in using CAM software such as Mastercam, Esprit, and NX CAM.

- Able to use CAD/CAM software to create 3D models, generate toolpaths, and simulate machining processes.

6. What is your experience with using precision measuring equipment, such as CMMs and optical comparators?

Answer:

- Proficient in using CMMs to inspect parts for dimensional accuracy.

- Experienced in using optical comparators to inspect parts for surface finish and flatness.

- Able to use precision measuring equipment to ensure that parts meet the required specifications.

7. What is your experience with working in a team environment?

Answer:

- Experienced in working as part of a team to develop and implement new machining processes.

- Able to communicate effectively with other team members.

- Willing to share knowledge and expertise with others.

8. What are your strengths and weaknesses as a machinist?

Answer:

Strengths

- Strong understanding of machining principles.

- Proficient in using CAD/CAM software.

- Experienced in using precision measuring equipment.

- Able to work independently and as part of a team.

- Committed to continuous learning and improvement.

Weaknesses

- Limited experience with some newer machining technologies.

- Need to improve time management skills.

9. What are your career goals?

Answer:

- To become a lead machinist and eventually a supervisor.

- To continue learning and developing my skills in the machining field.

- To contribute to the development of new and innovative machining processes.

10. Why are you interested in working for our company?

Answer:

- I am impressed by your company’s commitment to innovation.

- I believe that my skills and experience would be a valuable asset to your team.

- I am excited about the opportunity to contribute to the development of your company’s products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Research and Development Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Research and Development Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Research and Development Machinists are highly skilled professionals who play a critical role in the design and development of new products and technologies. They use their expertise in machining and fabrication to create prototypes, custom parts, and tools that are essential for research and development projects.

1. Design and Develop Prototypes

One of the primary responsibilities of a Research and Development Machinist is to design and develop prototypes. This involves working closely with engineers and designers to understand the specifications of the new product or technology. They then use their machining skills to create a physical model that can be tested and evaluated.

- Work closely with engineers and designers to understand the specifications of new products or technologies.

- Use machining skills to create physical models of prototypes.

- Test and evaluate prototypes to ensure that they meet the desired specifications.

2. Fabricate Custom Parts and Tools

In addition to creating prototypes, Research and Development Machinists also fabricate custom parts and tools. These parts and tools are often used in the development and testing of new products and technologies. They require a high level of precision and accuracy, and Research and Development Machinists must have the skills to create them.

- Fabricate custom parts and tools using a variety of machining techniques.

- Ensure that parts and tools meet the required specifications for accuracy and precision.

- Work with engineers and designers to develop and test new machining techniques.

3. Maintain and Calibrate Equipment

Research and Development Machinists must also be able to maintain and calibrate the equipment that they use. This includes cleaning, lubricating, and adjusting machines to ensure that they are operating properly. They must also be able to troubleshoot and repair machines when necessary.

- Maintain and calibrate a variety of machining equipment.

- Clean, lubricate, and adjust machines to ensure that they are operating properly.

- Troubleshoot and repair machines when necessary.

4. Stay Up-to-Date on New Technologies

The field of machining is constantly evolving, and Research and Development Machinists must stay up-to-date on the latest technologies. This includes attending training courses, reading technical journals, and networking with other machinists. By staying up-to-date on new technologies, Research and Development Machinists can ensure that they are using the most efficient and effective techniques in their work.

- Attend training courses to learn about new machining technologies.

- Read technical journals to stay up-to-date on the latest research and developments.

- Network with other machinists to share knowledge and ideas.

Interview Tips

Interviewing for a Research and Development Machinist position can be challenging, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the Company and the Position

Before you go on an interview, it is important to do your research on the company and the position. This will help you to understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on its website, social media pages, and Glassdoor. You can also learn about the position by reading the job description and talking to people who work in the field.

- Visit the company’s website to learn about its culture and values.

- Read the job description carefully to understand the specific requirements of the position.

- Talk to people who work in the field to get their insights on the job.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Prepare a brief introduction of yourself that highlights your skills and experience.

- Research the company and the position so that you can explain why you are interested in the job.

- Practice your answers to common interview questions out loud.

3. Be Prepared to Talk About Your Experience

The interviewer will likely want to know about your experience in the field of machining. Be prepared to talk about your skills and experience in detail. You should also be able to provide examples of your work.

- Highlight your skills and experience in the field of machining.

- Provide examples of your work to demonstrate your skills.

- Be prepared to answer questions about your experience in detail.

4. Ask Thoughtful Questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the company and the position. Ask thoughtful questions that show that you are interested in the job and that you have done your research.

- Ask about the company’s culture and values.

- Ask about the specific requirements of the position.

- Ask about the company’s plans for the future.

5. Follow Up After the Interview

After the interview, it is important to follow up with the interviewer. Thank them for their time and reiterate your interest in the position. You can also use this opportunity to provide any additional information that you think may be helpful.

- Send a thank-you note to the interviewer.

- Reiterate your interest in the position.

- Provide any additional information that you think may be helpful.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Research and Development Machinist interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!