Are you gearing up for an interview for a Residue Furnace Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Residue Furnace Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

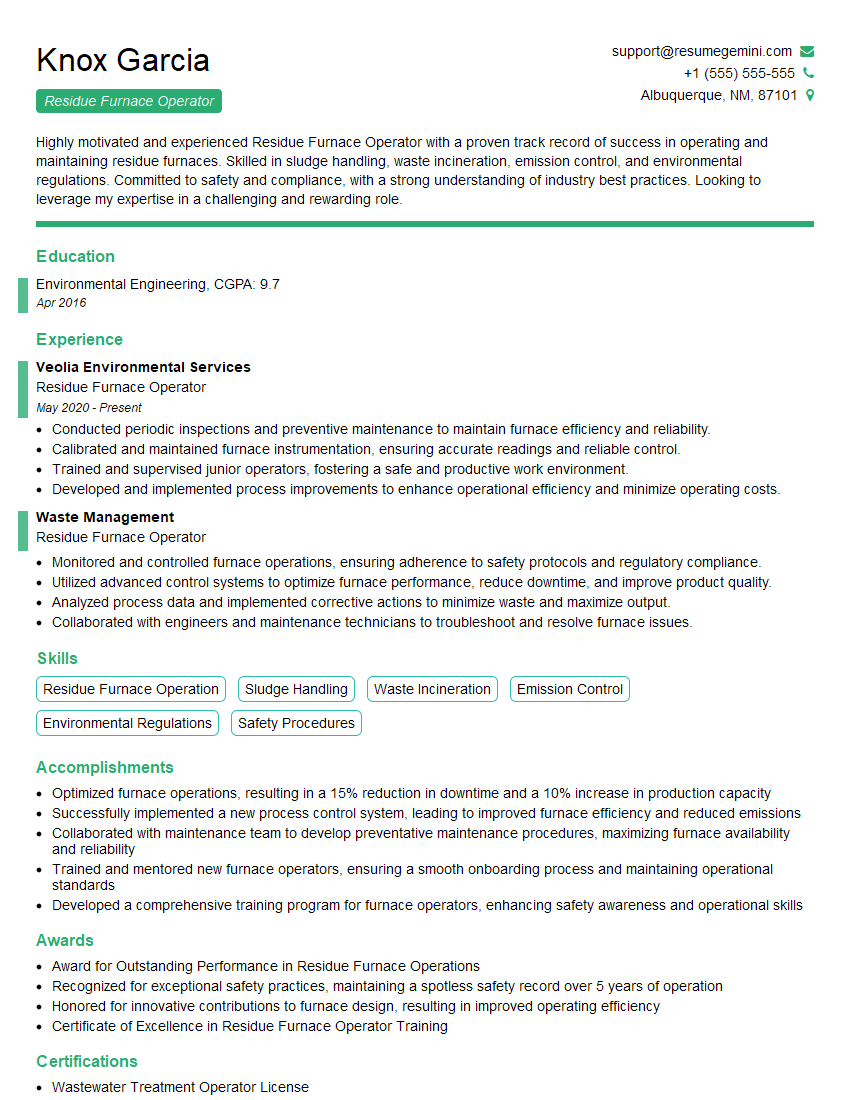

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Residue Furnace Operator

1. How would you monitor the efficiency of the residue furnace?

To monitor the efficiency of the residue furnace, I would use a combination of methods, including:

- Visual inspection: Regularly observing the furnace for any signs of wear or damage, such as cracks in the refractory lining or leaks in the piping.

- Temperature monitoring: Using thermocouples or other temperature-sensing devices to measure the temperature of the furnace at various points, such as the inlet and outlet streams.

- Flow rate monitoring: Using flow meters to measure the flow rate of the feedstock and combustion gases entering and exiting the furnace.

- Mass balance calculations: Comparing the mass of the feedstock entering the furnace to the mass of the products exiting the furnace to determine the overall efficiency of the process.

2. What are the key safety precautions that must be followed when operating a residue furnace?

- Wear appropriate personal protective equipment (PPE): This includes a fire-resistant suit, gloves, safety goggles, and a respirator.

- Follow proper start-up and shutdown procedures: This includes ensuring that all valves are closed before starting the furnace and that the furnace is properly cooled down before shutting it down.

- Maintain a clean and organized work area: This helps to prevent accidents and ensures that all equipment is operating properly.

- Be aware of the potential hazards associated with the feedstock and products: This includes the potential for fire, explosion, and toxic fumes.

- Have a plan in place for emergency situations: This includes knowing how to shut down the furnace safely and how to evacuate the area.

3. How would you troubleshoot a problem with the furnace’s temperature control system?

- Check the thermocouples or other temperature-sensing devices: Make sure that they are properly calibrated and that they are making good contact with the furnace.

- Check the temperature controller: Make sure that it is properly configured and that it is receiving the correct input from the temperature-sensing devices.

- Check the actuators: Make sure that they are properly connected to the temperature controller and that they are functioning properly.

- Check the fuel supply: Make sure that the furnace is receiving the correct amount of fuel and that the fuel is of the correct quality.

4. What are the different types of feedstocks that can be used in a residue furnace?

- Petroleum coke: A solid carbonaceous material that is produced as a byproduct of petroleum refining.

- Coal tar pitch: A viscous, black liquid that is produced as a byproduct of coal tar distillation.

- Biomass: Organic matter that is derived from plants or animals, such as wood chips, sawdust, or animal fat.

- Municipal solid waste: A heterogeneous mixture of materials that is produced by households and businesses, such as paper, plastic, and food waste.

5. What are the environmental regulations that apply to the operation of a residue furnace?

- Clean Air Act: This act regulates the emission of air pollutants from industrial sources, including residue furnaces.

- Clean Water Act: This act regulates the discharge of pollutants into waterways, including the wastewater from residue furnaces.

- Resource Conservation and Recovery Act: This act regulates the handling and disposal of hazardous waste, including the waste generated by residue furnaces.

6. How would you calculate the heating value of a feedstock?

The heating value of a feedstock is a measure of the amount of energy that is released when the feedstock is burned.

- Bomb calorimetry: This is a laboratory test in which a sample of the feedstock is burned in a sealed container and the heat released is measured.

- Dulong’s formula: This is an empirical formula that can be used to estimate the heating value of a feedstock based on its elemental composition.

7. What are the different types of burners that can be used in a residue furnace?

- Air-atomized burners: These burners use compressed air to atomize the fuel oil, which is then mixed with combustion air and burned.

- Steam-atomized burners: These burners use steam to atomize the fuel oil, which is then mixed with combustion air and burned.

- Rotary cup burners: These burners use a rotating cup to atomize the fuel oil, which is then mixed with combustion air and burned.

- Pressure-jet burners: These burners use a high-pressure stream of fuel oil to atomize the fuel, which is then mixed with combustion air and burned.

8. What are the advantages and disadvantages of using a fluidized bed furnace?

Advantages

- High thermal efficiency: Fluidized bed furnaces can achieve high thermal efficiency due to the good contact between the fuel and the bed material.

- Low emissions: Fluidized bed furnaces can produce lower emissions of pollutants, such as NOx and SOx, due to the staged combustion process.

- Flexibility: Fluidized bed furnaces can burn a wide range of feedstocks, including low-grade fuels.

Disadvantages

- High capital cost: Fluidized bed furnaces can be more expensive to build and maintain than other types of furnaces.

- Complex operation: Fluidized bed furnaces require careful control of the bed temperature and flow rate to ensure stable operation.

9. What are the different types of refractory materials that can be used in a residue furnace?

- Fireclay: A type of clay that is used to make refractory bricks and other shapes.

- High-alumina: A type of refractory material that is made from bauxite and has a high alumina content.

- Silicon carbide: A type of refractory material that is made from silicon and carbon and has a high thermal conductivity.

- Magnesia: A type of refractory material that is made from magnesium oxide and has a high thermal stability.

10. What are the key performance indicators (KPIs) that are used to measure the performance of a residue furnace?

- Thermal efficiency: The ratio of the heat output of the furnace to the heat input of the fuel.

- Emissions: The amount of pollutants, such as NOx and SOx, that are emitted from the furnace.

- Feedstock consumption: The amount of feedstock that is required to produce a given amount of heat.

- Availability: The percentage of time that the furnace is available to operate.

- Reliability: The percentage of time that the furnace operates without any major breakdowns.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Residue Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Residue Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Residue Furnace Operators play a vital role in the industrial setting, ensuring the efficient and safe operation of furnaces that process hazardous and combustible materials. Their key responsibilities include:

1. Furnace Operation and Maintenance

Operate and monitor furnaces, ensuring they function according to specifications. This involves controlling temperatures, adjusting fuel flow, and maintaining equipment.

- Monitor and adjust furnace controls to optimize performance.

- Perform routine maintenance and repairs to prevent breakdowns.

2. Waste Management

Manage hazardous and combustible waste materials, including loading and unloading materials into the furnace.

- Follow safety protocols for handling and disposing of hazardous materials.

- Ensure proper waste disposal according to environmental regulations.

3. Safety and Compliance

Uphold strict safety standards and comply with industry regulations.

- Wear appropriate personal protective equipment (PPE).

- Monitor and maintain a safe work environment.

- Report any safety concerns or potential hazards.

4. Maintenance and Troubleshooting

Perform regular maintenance and troubleshooting to minimize downtime.

- Inspect and clean equipment regularly.

- Identify and resolve equipment malfunctions.

Interview Tips

To prepare for a Residue Furnace Operator interview, consider these tips:

1. Research the Company and the Role

Familiarize yourself with the company’s industry, mission, and the specific responsibilities of the role. This knowledge demonstrates your interest and understanding of the position.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating and maintaining furnaces, as well as your knowledge of safety procedures and waste management practices. Provide specific examples of your experience.

- Describe your experience in operating different types of furnaces.

- Share examples of how you have resolved equipment malfunctions.

3. Demonstrate Your Safety Awareness

Stress your commitment to safety and your understanding of the importance of following safety protocols. Highlight any relevant training or certifications you possess.

- Mention your knowledge of OSHA regulations and industry best practices.

- Explain your experience in using personal protective equipment.

4. Prepare for Behavioral Questions

Interviewers may ask behavioral questions to assess your teamwork skills, problem-solving abilities, and work ethic. Prepare examples that demonstrate your initiative, attention to detail, and ability to handle challenges.

- Describe a time when you worked effectively as part of a team.

- Share an example of how you solved a problem or resolved a conflict.

5. Ask Informed Questions

At the end of the interview, asking thoughtful questions shows your engagement and interest. Prepare questions about the company’s safety culture, environmental policies, or opportunities for professional development.

- Ask about the company’s commitment to safety and environmental compliance.

- Inquire about the opportunities for advancement and training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Residue Furnace Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!