Are you gearing up for an interview for a Resin Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Resin Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

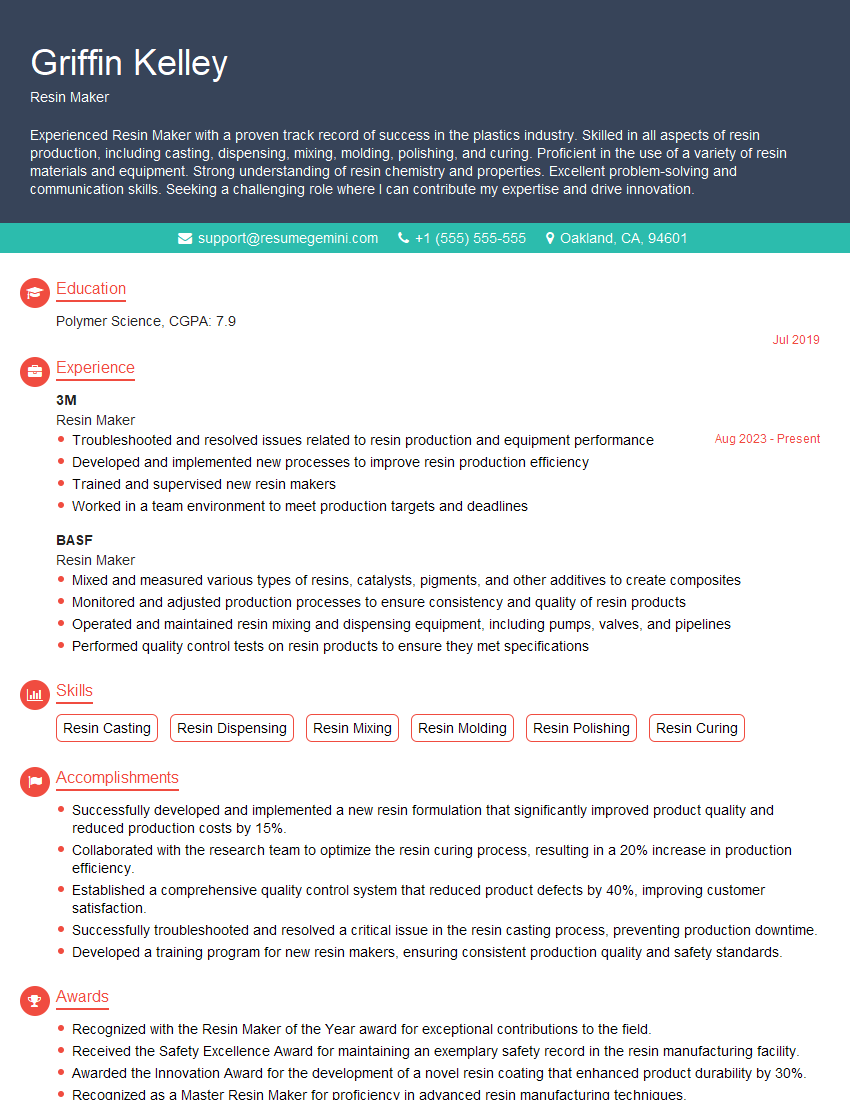

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Resin Maker

1. Describe the key steps involved in the resin making process?

- Mixing raw materials: This involves combining the appropriate amounts of resin, hardener, and any additives.

- Degassing: Removing air bubbles from the mixture to prevent voids and ensure proper bonding.

- Casting: Pouring the resin mixture into molds or onto surfaces to create the desired shape.

- Curing: Allowing the resin to undergo a chemical reaction that hardens and strengthens it.

- Post-processing: Trimming, sanding, or polishing the cured resin to achieve the desired appearance and finish.

2. What types of resins have you worked with? Can you explain the differences between them?

Epoxy Resins

- Strong and durable

- Excellent chemical and solvent resistance

- High temperature resistance

Polyester Resins

- Cost-effective and easy to use

- Lower strength and durability compared to epoxy resins

- Susceptible to yellowing and degradation over time

Acrylic Resins

- Clear and transparent

- Excellent UV resistance

- Lower hardness and strength compared to epoxy resins

3. How do you ensure the quality and consistency of your resin products?

- Using high-quality raw materials from trusted suppliers

- Following established mixing and curing procedures

- Conducting regular testing and inspections to monitor product specifications

- Maintaining a clean and controlled work environment

- Documenting processes and adhering to quality standards

4. Describe the safety precautions you take when working with resins?

- Wearing appropriate personal protective equipment (PPE) including gloves, eye protection, and a respirator

- Ensuring adequate ventilation to prevent inhalation of fumes

- Storing and handling resins properly to prevent accidents and spills

- Following manufacturer’s safety instructions and datasheets

- Being aware of the potential hazards associated with resins, such as skin irritation and respiratory problems

5. What is the importance of degassing resin mixtures? How do you effectively remove air bubbles?

- Degassing removes air bubbles that can weaken the final product and create voids.

- Effective degassing methods include using a vacuum chamber, applying heat, or using a mechanical agitator.

- Proper degassing ensures a strong and homogeneous resin structure.

6. How do you determine the optimal curing time for different resin systems?

- Refer to manufacturer’s specifications and technical data sheets.

- Consider the ambient temperature, humidity, and resin thickness.

- Use curing ovens or controlled environments to ensure proper curing conditions.

- Test cured samples to assess hardness, strength, and other properties.

7. What techniques do you use to create complex or intricate resin castings?

- Using multi-part molds

- Creating master patterns and reproducing them in silicone molds

- Incorporating fillers, pigments, and other materials to enhance aesthetics

- Employing layering and casting techniques to achieve desired effects

8. How do you handle and dispose of hazardous waste generated during the resin making process?

- Following local and industry regulations for waste disposal

- Using designated containers for hazardous waste

- Properly labeling and storing waste until it can be disposed of

- Working with licensed waste management companies

9. What are some common defects that can occur in resin castings and how do you prevent them?

Voids:

- Insufficient mixing or degassing

- Preventing by proper mixing and degassing techniques

Cracks:

- Excessive stress or shrinkage

- Preventing by using appropriate molds, controlling curing conditions, and avoiding rapid temperature changes

Discoloration:

- Exposure to UV light or heat

- Preventing by using UV inhibitors or storing resins in protected conditions

10. How do you stay up-to-date with the latest advancements and best practices in the resin industry?

- Attending industry conferences and workshops

- Reading technical journals and publications

- Networking with other professionals in the field

- Seeking training and certification opportunities

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Resin Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Resin Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Resin Maker, you play a crucial role in creating and maintaining the highest quality resins for various industrial and commercial applications. Your key responsibilities involve the following:

1. Resin Production and Formulation

You are responsible for operating and maintaining resin production equipment to manufacture resins accurately per specified formulas and standards.

- Precisely weigh and mix raw materials, ensuring correct proportions and quality.

- Monitor and control production variables such as temperature, pressure, and stirring speed to optimize resin properties.

2. Quality Control and Testing

You conduct quality control tests on raw materials and finished resins to ensure they meet specifications and customer requirements.

- Perform chemical and physical tests, including viscosity, solids content, and curing time, to evaluate resin quality.

- Troubleshoot and identify deviations from specifications, implementing corrective actions to maintain quality.

3. Equipment Operation and Maintenance

You are responsible for maintaining and operating production equipment efficiently and safely.

- Clean and calibrate equipment regularly to ensure optimal functionality and consistency.

- Perform minor repairs and maintenance tasks to minimize downtime and maintain equipment performance.

4. Safety and Environmental Compliance

As a Resin Maker, you adhere to strict safety and environmental regulations to ensure a safe and compliant work environment.

- Follow established safety protocols, wear appropriate personal protective equipment, and handle hazardous materials safely.

- Comply with environmental regulations and dispose of waste materials responsibly to minimize ecological impact.

Interview Tips

To ace your Resin Maker interview, it’s essential to prepare thoroughly and highlight your relevant skills and experience. Here are some tips to help you succeed:

1. Research the Company and Industry

Before the interview, familiarize yourself with the company’s products, services, and industry trends. Demonstrate your knowledge and interest in the company by asking insightful questions.

- Visit the company’s website and review their annual reports to gather information about their business.

- Read industry publications and news to stay updated on the latest developments and best practices.

2. Practice Your Technical Skills

As a Resin Maker, your technical abilities are crucial. Review your knowledge of resin production, quality control, equipment troubleshooting, and safety practices.

- Prepare to discuss your experience in using specific resin production techniques and equipment.

- Practice answering questions about resin testing and quality control procedures.

3. Highlight Your Safety and Environmental Awareness

Emphasize your commitment to safety and environmental compliance in the interview. Describe your experience in handling hazardous materials, adhering to safety protocols, and promoting a safe work environment.

- Explain your understanding of OSHA regulations and industry best practices for handling resins.

- Share examples of how you have implemented environmental initiatives or promoted sustainable practices in your previous roles.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role. Prepare questions that demonstrate your knowledge of the company, the industry, or specific aspects of the job.

- Ask about the company’s growth plans and innovation initiatives.

- Inquire about the challenges and opportunities the company faces in the industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Resin Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.