Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Resistance Brazer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

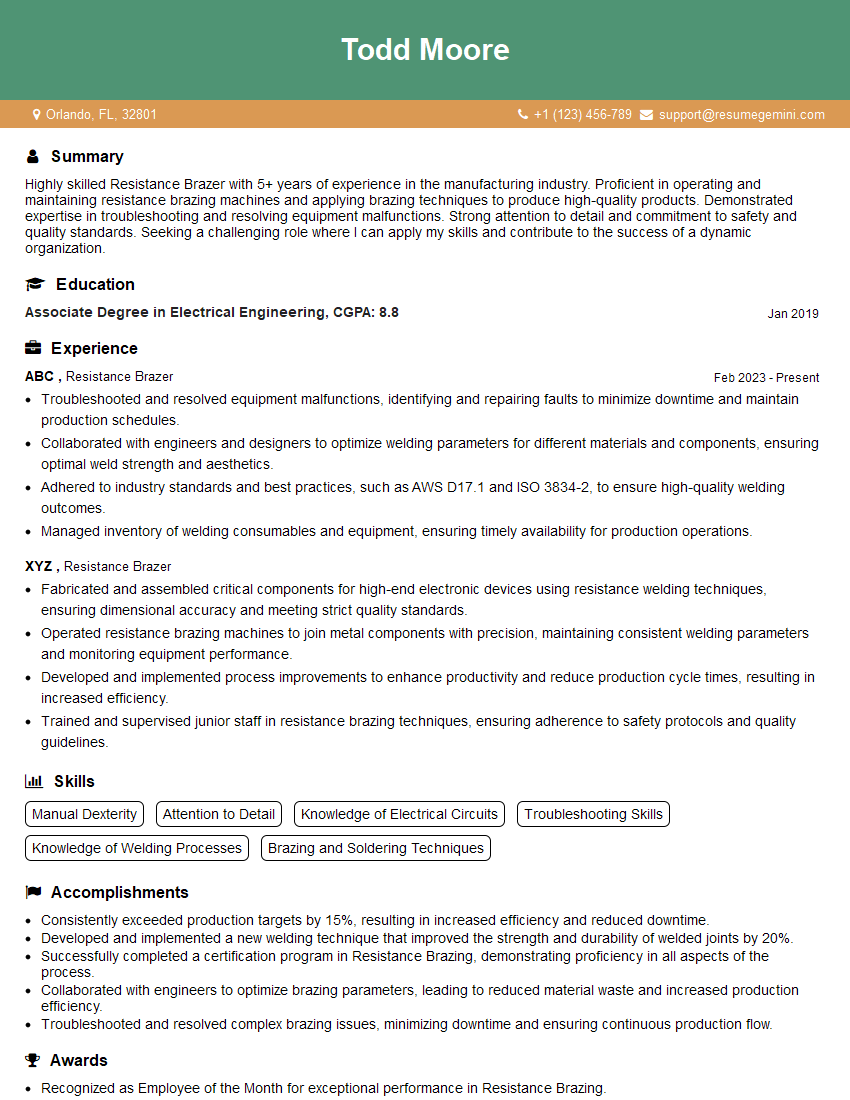

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Resistance Brazer

1. Describe the process of resistance brazing?

Resistance brazing is a metal joining process that uses heat generated by the resistance to the flow of electric current between the faying surfaces of the materials being joined. The heat generated melts a brazing filler metal, which is drawn into the joint by capillary action. Resistance brazing is often used to join electrical components, such as terminals, connectors, and wires.

- The process begins by cleaning the surfaces to be joined and applying a flux.

- The parts are then placed in a fixture that holds them in place and applies pressure.

- An electric current is then passed through the parts, causing them to heat up.

- The brazing filler metal is then applied to the joint, and it melts and flows into the joint by capillary action.

- The current is then turned off, and the joint is allowed to cool.

2. What are the advantages of resistance brazing?

Efficiency

- Resistance brazing is a very efficient process, as it generates heat directly in the joint area.

- This means that there is very little heat loss, and the process is very fast.

Quality

- Resistance brazing produces high-quality joints that are strong and durable.

- The process is also very precise, and it can be used to join a wide variety of materials.

3. What are the disadvantages of resistance brazing?

- Resistance brazing can be more expensive than other joining methods, such as soldering or welding.

- The process can also be more complex, and it requires specialized equipment.

4. What are the different types of resistance brazing machines?

- There are two main types of resistance brazing machines: benchtop machines and floor-standing machines.

- Benchtop machines are smaller and less powerful than floor-standing machines, and they are typically used for smaller jobs.

- Floor-standing machines are larger and more powerful, and they are typically used for larger jobs.

5. What are the safety precautions that must be taken when operating a resistance brazing machine?

- When operating a resistance brazing machine, it is important to take the following safety precautions:

- Wear proper safety gear, including gloves, safety glasses, and a face shield.

- Make sure that the machine is properly grounded.

- Do not touch the electrodes or the workpiece while the machine is operating.

- Keep the work area clean and free of flammable materials.

6. How do you troubleshoot a resistance brazing machine?

- If a resistance brazing machine is not working properly, there are a few things that you can do to troubleshoot the problem:

- Check the power supply to make sure that the machine is getting power.

- Check the electrodes to make sure that they are clean and free of oxidation.

- Check the workpiece to make sure that it is clean and free of contaminants.

- Check the pressure settings to make sure that they are correct.

- If the problem persists, you may need to contact a qualified technician.

7. What are the different types of brazing filler metals?

- There are a variety of different brazing filler metals available, each with its own unique properties.

- The most common type of brazing filler metal is silver-based, but there are also copper-based, aluminum-based, and nickel-based brazing filler metals.

- The type of brazing filler metal that is used will depend on the materials being joined and the desired properties of the joint.

8. What is the difference between resistance brazing and induction brazing?

- Resistance brazing and induction brazing are two different metal joining processes that use heat to melt a brazing filler metal.

- Resistance brazing uses heat generated by the resistance to the flow of electric current, while induction brazing uses heat generated by induction.

- Resistance brazing is typically used for smaller jobs, while induction brazing is typically used for larger jobs.

9. What is the difference between resistance brazing and soldering?

- Resistance brazing and soldering are two different metal joining processes that use heat to melt a filler metal.

- Resistance brazing uses a higher temperature than soldering, and it produces a stronger joint.

- Resistance brazing is also more expensive than soldering, and it requires more specialized equipment.

10. What are the applications of resistance brazing?

- Resistance brazing is used in a wide variety of applications, including:

- Automotive

- Aerospace

- Medical

- Electrical

- Electronics

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Resistance Brazer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Resistance Brazer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Resistance Brazers are widely used in the manufacturing industry for their ability to perform precise and fast joining of metal components. They often work in highly skilled teams within a production or assembly environment. Here are some of the key job responsibilities of a Resistance Brazer:1. Brazing Operations

Resistance Brazers are responsible for operating resistance brazing machines. This involves setting up the machine, loading components, and initiating the brazing process. They must be able to monitor the process and make adjustments as needed to ensure that the brazed joints meet the required specifications.

2. Quality Control

Resistance Brazers are responsible for ensuring that the brazed joints meet the required quality standards. They inspect the joints for defects, such as cracks, voids, and misalignment. They also perform destructive and non-destructive testing to ensure that the joints meet the required strength and durability requirements.

3. Machine Maintenance

Resistance Brazers are responsible for maintaining the resistance brazing machines. This involves cleaning, lubricating, and adjusting the machines as needed. They also perform minor repairs and troubleshoot any problems that may arise.

4. Material Handling

Resistance Brazers are responsible for handling the materials that are being brazed. This involves loading and unloading the machines, as well as moving the materials around the work area. They must be able to handle heavy materials and work in a fast-paced environment.

Interview Tips

Here are some interview tips for Resistance Brazers:1. Research the Company and the Position

Before going to the interview, take some time to research the company and the position. This will help you have a better understanding of what the company does, the position you are applying for, and the company culture. You can find information about the company on their website, social media pages, and Glassdoor reviews.

2. Practice Your Answers

Once you have a good understanding of the company and the position, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

4. Be on Time

Punctuality is important, so be sure to arrive on time for your interview. If you are running late, call the interviewer to let them know and apologize.

5. Be Enthusiastic and Positive

Employers want to hire people who are enthusiastic and positive about their work. Make sure to convey this enthusiasm and positivity during your interview.

6. Ask Questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the job and the company culture.

7. Follow Up

After the interview, follow up with the interviewer by sending a thank-you note. This will help you stay top of mind and show your appreciation for the opportunity to interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Resistance Brazer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.