Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Resistance Welding Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Resistance Welding Machine Operator so you can tailor your answers to impress potential employers.

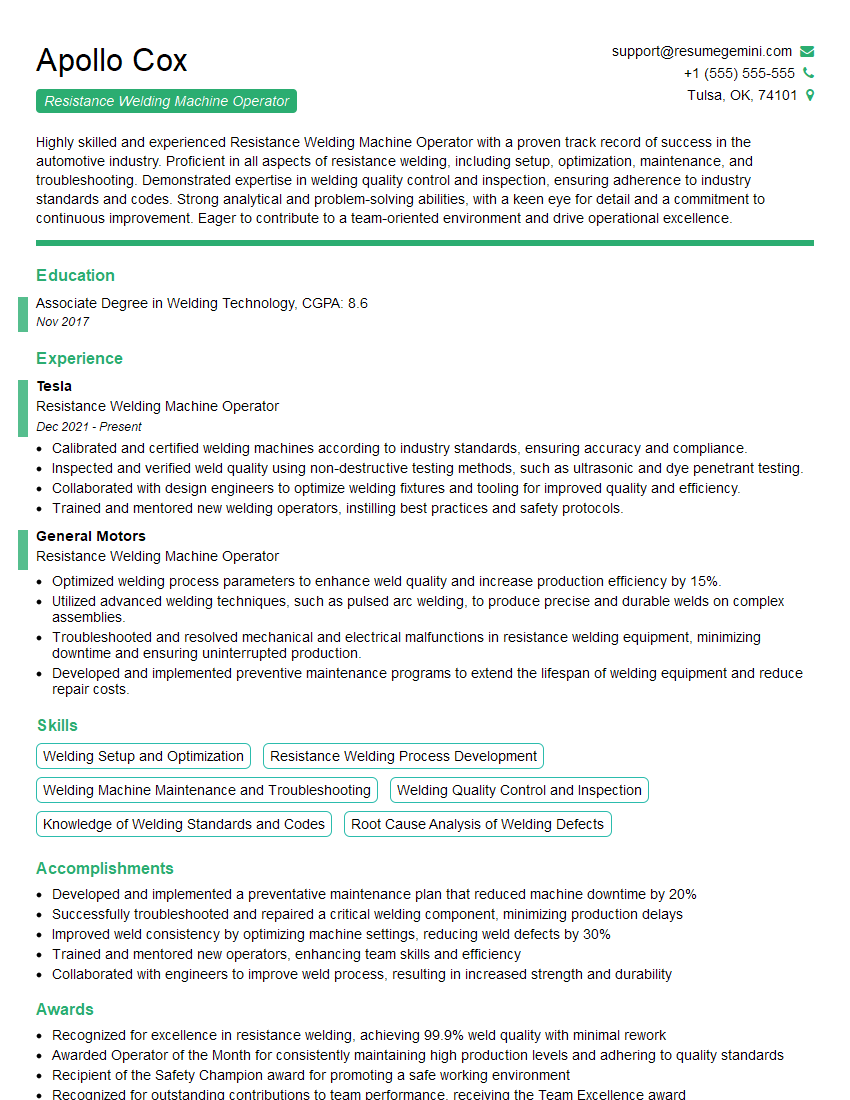

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Resistance Welding Machine Operator

1. How do you set up and calibrate a resistance welding machine?

answer

- Verify equipment is powered off. Lockout/Tagout.

- Install welding tips. Usually, the tips should be at 120 and 240 degrees.

- Close the secondary loop.

- Calibrate reset (if applicable).

- Calibrate cleave height.

- Set weld voltage.

- Calibrate weld time.

- Calibration weld.

- Measure weld and inspect for quality.

2. What are the welding parameters for autogenous welding?

Resistance welding material

- Low carbon steel (0.15%C)

Welding parameter

- Welding force (N): 5 – 20 kN

- Welding current (kA): 12 – 30 kA

- Welding time (cycle) : 0.05 – 0.5 s

- Forging force (N): 5 – 15 kN

- Forging time (cycle): 0.1 – 0.5 s

3. How do you troubleshoot a resistance welding machine that is not welding properly?

answer

- Check power supply.

- Check transformer.

- Check welder cable and connections.

- Check welding tips.

- Check weld schedule.

- Check for any other potential mechanical issues.

4. What is the difference between spot welding and seam welding?

answer

- Spot welding is a welding process that joins two pieces of metal by applying pressure and heat to a small, localized area.

- Seam welding is a welding process that joins two pieces of metal by applying pressure and heat to a continuous seam.

5. What are the advantages and disadvantages of resistance welding?

Advantages:

- Resistance welding is a fast and efficient welding process.

- It is a relatively inexpensive welding process.

- Resistance welding produces strong and consistent welds.

Disadvantages:

- Resistance welding can only be used to weld metals that are good conductors of electricity.

- The heat generated by resistance welding can damage the surrounding metal.

- Resistance welding can be difficult to set up and calibrate.

6. What are the safety precautions that must be taken when operating a resistance welding machine?

answer

- Wear protective clothing, including gloves, safety glasses, and a welding helmet.

- Make sure the welding area is well-ventilated.

- Keep the welding machine in good working order.

- Follow all safety instructions provided by the manufacturer.

7. What is the future of resistance welding?

answer

- Resistance welding is a well-established welding process that is likely to continue to be used in the future.

- However, there are a number of new developments that are likely to impact the future of resistance welding.

- These developments include the use of new materials, new welding techniques, and new equipment.

8. What are the different types of tips used for spot welding?

answer

- Flat tips

- Domed tips

- Spherical tips

9. What are the different types of weld timers used for resistance welding?

answer

- Single-phase timers

- Three-phase timers

- Digital timers

10. What are the different types of welding guns used for resistance welding?

answer

- Pistol-grip guns

- C-frame guns

- Robotic guns

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Resistance Welding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Resistance Welding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Resistance Welding Machine Operators play a crucial role in manufacturing processes, operating advanced welding machines to join metal components. Their key responsibilities include:

1. Welding Metal Components

Using resistance welding machines, operators weld metal components together based on specified designs and instructions.

2. Setting Up and Maintaining Welding Equipment

Operators set up and calibrate welding machines, ensuring they are operating optimally. They also perform regular maintenance to keep equipment in good working condition.

3. Monitoring Welding Processes

Operators monitor the welding process to ensure it complies with quality standards. They adjust machine parameters as needed to maintain consistent weld quality.

4. Inspecting Welded Joints

Operators visually inspect welded joints to check for defects. They use measuring instruments to ensure welds meet specifications and quality standards.

5. Maintaining Work Area

Operators maintain a clean and organized work area, ensuring that equipment is properly stored and safety protocols are followed.

Interview Tips

To ace an interview for a Resistance Welding Machine Operator role, candidates should consider the following tips:

1. Research the Company and Role

Before the interview, research the company’s history, products or services, and the specific responsibilities of the Resistance Welding Machine Operator position. This demonstrates your interest and preparedness.

2. Highlight Relevant Skills and Experience

Emphasize your hands-on experience operating welding machines, especially resistance welding equipment. Quantify your accomplishments by providing specific examples of successful welding projects.

3. Demonstrate Safety Awareness

Resistance welding involves working with electrical equipment and hazardous materials. Highlight your understanding of safety protocols and your commitment to maintaining a safe work environment.

4. Show Your Problem-Solving Abilities

Interviewers may ask hypothetical questions to gauge your problem-solving skills. Describe situations where you encountered welding challenges and explain how you resolved them.

5. Be Prepared to Discuss Quality Control

Quality control is paramount in welding. Explain your knowledge of welding standards and inspection techniques, and demonstrate your commitment to delivering high-quality welds.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Resistance Welding Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.