Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Restrike Hammer Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

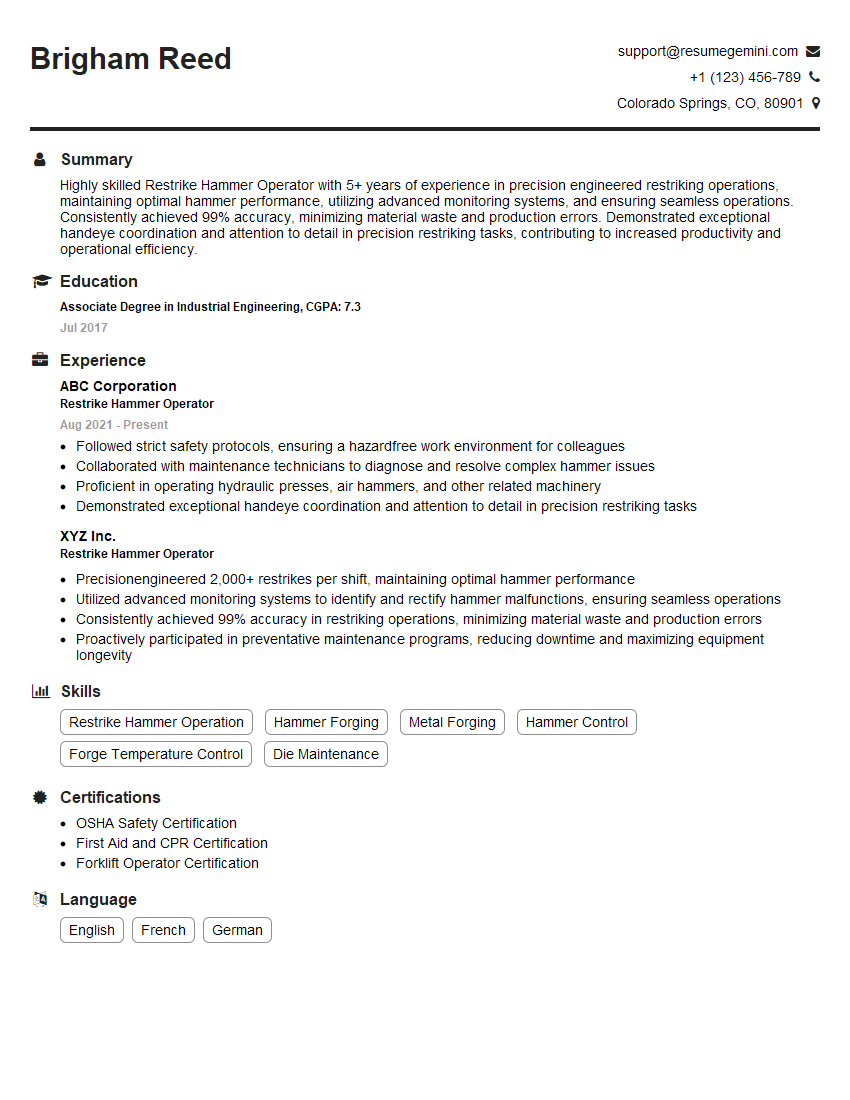

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Restrike Hammer Operator

1. Describe the key responsibilities of a Restrike Hammer Operator.

As a Restrike Hammer Operator, my primary responsibilities include:

- Operating a restrike hammer to forge and shape metal components.

- Interpreting engineering drawings and technical specifications to determine production requirements.

- Setting up and adjusting the restrike hammer to achieve the desired shape and dimensions.

- Monitoring the forging process and making adjustments as necessary to ensure quality and efficiency.

- Performing inspections and quality control checks on finished components.

2. Explain the different types of restrike hammers and their applications.

Mechanical Restrike Hammers

- Driven by a crankshaft or eccentric mechanism.

- Used for heavy-duty forging, such as in automotive and aerospace manufacturing.

Hydraulic Restrike Hammers

- Powered by hydraulic pressure.

- Offer greater control over forging force and precision.

- Suitable for smaller and more intricate components.

Pneumatic Restrike Hammers

- Driven by compressed air.

- Lightweight and portable, making them ideal for field operations.

- Used for lighter forging applications, such as jewelry making.

3. What are the safety precautions that need to be taken when operating a restrike hammer?

- Wearing appropriate personal protective equipment, such as gloves, safety glasses, and earplugs.

- Ensuring the work area is clear and free of obstructions.

- Inspecting the restrike hammer and dies regularly for damage or wear.

- Following lockout/tagout procedures when performing maintenance or repairs.

- Never operating the hammer while under the influence of drugs or alcohol.

4. Describe the process of setting up and adjusting a restrike hammer.

The process involves:

- Selecting the appropriate dies for the desired shape and dimensions.

- Installing the dies securely in the hammer.

- Adjusting the hammer’s stroke length, force, and speed.

- Testing the hammer’s operation with scrap material to ensure proper setup.

- Making fine adjustments as needed to optimize the forging process.

5. How do you determine the optimal forging temperature for different types of metals?

The optimal forging temperature depends on the type of metal being forged:

- Steel: Typically forged between 1200°C to 1400°C (2192°F to 2552°F).

- Aluminum: Forged between 450°C to 600°C (842°F to 1112°F).

- Copper: Forged between 700°C to 900°C (1292°F to 1652°F).

- Titanium: Forged between 900°C to 1100°C (1652°F to 2012°F).

6. What are the common defects that can occur during restrike forging and how can they be prevented?

- Cracks: Caused by excessive force or improper heating. Prevention: Use the correct forging temperature and apply force gradually.

- Lapse: Occurs when metal folds over on itself. Prevention: Use dies with matching contours and apply pressure evenly.

- Flash: Excess metal that extends beyond the die cavity. Prevention: Use dies with proper clearance and adjust the forging force accordingly.

- Cold shuts: Unfused areas in the forged metal. Prevention: Ensure the metal is heated to the correct forging temperature and apply sufficient force.

7. Explain the importance of die design in restrike forging.

- Determines the final shape and dimensions of the forged component.

- Affects the metal flow and the distribution of stress during forging.

- Die design should consider factors such as die cavity shape, draft angles, and material properties.

- Proper die design can improve forging efficiency and reduce the risk of defects.

8. Describe how you maintain and troubleshoot a restrike hammer.

Regular maintenance includes:

- Inspecting and lubricating moving parts.

- Checking and replacing worn or damaged dies.

- Monitoring hydraulic or pneumatic systems for leaks or pressure issues.

Troubleshooting involves:

- Identifying the source of the problem through visual inspection and diagnostic tests.

- Performing repairs or adjustments as necessary.

- Calibrating and testing the hammer to ensure proper operation.

9. How do you ensure the quality of forged components?

- Performing visual inspections to check for defects such as cracks or lapses.

- Using measuring tools to verify dimensions and tolerances.

- Conducting hardness tests to ensure the desired material properties.

- Following quality control procedures and adhering to industry standards.

10. Explain how you stay up-to-date with industry best practices in restrike forging.

- Attending industry conferences and workshops.

- Reading technical publications and journals.

- Consulting with experts and sharing knowledge with colleagues.

- Participating in training programs and certifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Restrike Hammer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Restrike Hammer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Restrike Hammer Operators are responsible for operating restrike hammers used to shape metal. They work in the metalworking industry, following instructions provided by engineering drawings or verbal instructions from supervisors.

1. Hammer Operation

Operate restrike hammers according to specifications and ensure that the hammer is correctly adjusted and calibrated.

- Set up and operate restrike hammers to shape metal components.

- Monitor hammer operations and make adjustments to ensure quality and efficiency.

2. Metal Shaping

Shape metal components using restrike hammers, following engineering drawings or verbal instructions.

- Use hand tools and measuring instruments to ensure accuracy and precision.

- Inspect finished components to ensure they meet quality standards.

3. Maintenance

Perform basic maintenance and repairs on restrike hammers and associated equipment.

- Clean and lubricate hammers and other equipment regularly.

- Troubleshoot and resolve minor operational issues.

4. Safety

Follow safety protocols and wear appropriate personal protective equipment.

- Adhere to safety regulations and guidelines.

- Maintain a clean and organized work area.

Interview Tips

To prepare for an interview as a Restrike Hammer Operator, there are several tips and hacks you can follow to increase your chances of success.

1. Research the Company

Before the interview, take the time to research the company you’re applying to. Familiarize yourself with their products, services, and industry reputation. This knowledge will enable you to understand the company’s needs and how your skills and experience can contribute to their success.

2. Practice Your Answers

Anticipate common interview questions and formulate thoughtful answers. Practice delivering your answers clearly and concisely. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

3. Highlight Relevant Experience

In your interview, emphasize your experience and skills that are directly relevant to the job responsibilities of a Restrike Hammer Operator. Quantify your accomplishments whenever possible, using specific examples and metrics.

4. Demonstrate Safety Awareness

Safety is paramount in the metalworking industry. During the interview, confidently articulate your understanding of safety protocols and your commitment to maintaining a safe work environment.

5. Ask Informed Questions

Asking well-informed questions at the end of the interview demonstrates your interest and engagement. Prepare a few thoughtful questions that show you’ve listened attentively and are eager to learn more about the role and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Restrike Hammer Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!