Are you gearing up for a career in Retort Furnace Helper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Retort Furnace Helper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

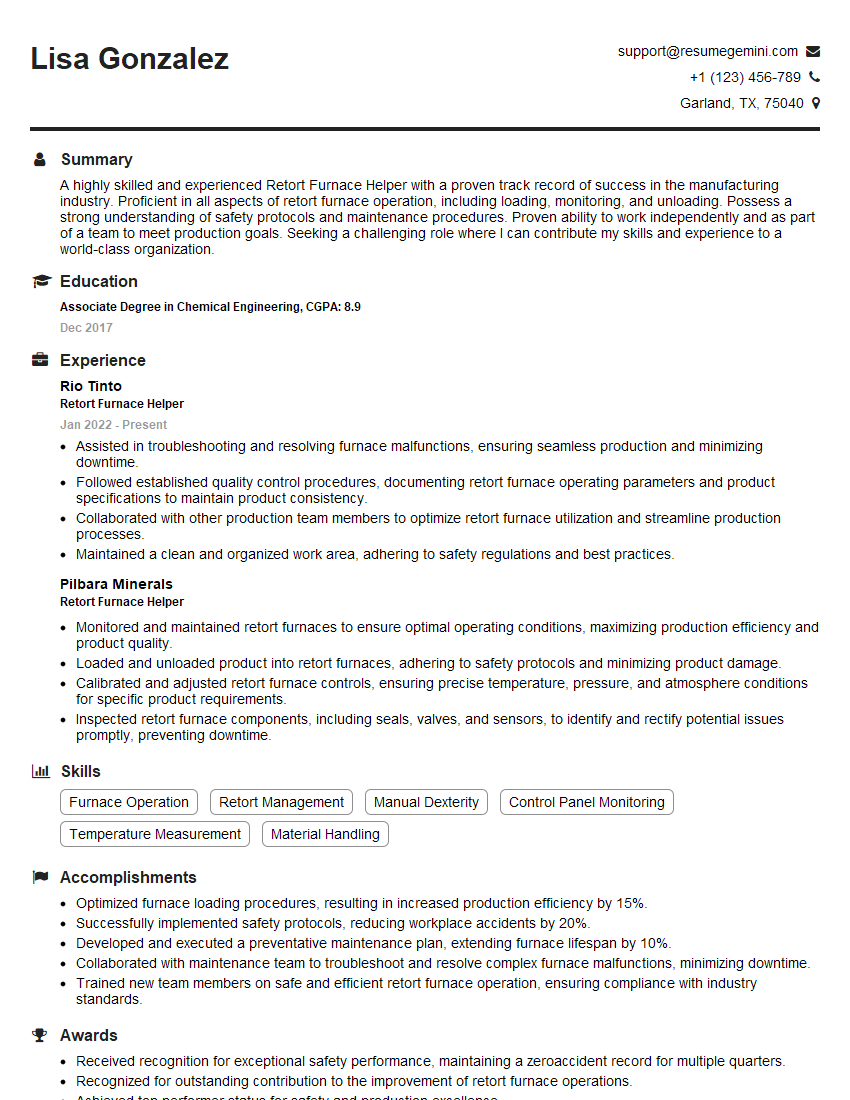

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Retort Furnace Helper

1. What are the key responsibilities of a Retort Furnace Helper?

The primary responsibilities of a Retort Furnace Helper include:

- Loading and unloading retorts into and out of the retort furnace

- Monitoring the retort furnace to ensure proper operation

- Maintaining a clean and safe work area

- Following all safety procedures

2. What is the difference between a retort and a muffle furnace?

Retort Furnace

- A retort furnace is a type of furnace that uses a sealed container to hold the materials being heated.

- This allows the materials to be heated in a controlled atmosphere.

Muffle Furnace

- A muffle furnace is a type of furnace that uses a chamber to hold the materials being heated.

- The chamber is surrounded by heating elements, which heat the materials indirectly.

3. What are the safety precautions that should be taken when working with a retort furnace?

The following safety precautions should be taken when working with a retort furnace:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator.

- Never open the retort furnace door while it is in operation.

- Be aware of the potential for explosions if the retort furnace is not properly vented.

- Never leave the retort furnace unattended while it is in operation.

4. What are the different types of materials that can be heated in a retort furnace?

A variety of materials can be heated in a retort furnace, including:

- Metals

- Ceramics

- Glasses

- Plastics

5. What are the different types of atmospheres that can be used in a retort furnace?

A variety of atmospheres can be used in a retort furnace, including:

- Air

- Nitrogen

- Hydrogen

- Vacuum

6. What are the factors that affect the heating rate of a retort furnace?

The following factors affect the heating rate of a retort furnace:

- The type of material being heated

- The size of the retort

- The temperature of the furnace

- The atmosphere in the furnace

7. What are the different types of retort furnaces?

The following are the different types of retort furnaces:

- Batch retort furnaces

- Continuous retort furnaces

- Vacuum retort furnaces

- Atmosphere retort furnaces

8. What is the annealing process?

Annealing is a heat treatment process that involves heating a material to a high temperature and then slowly cooling it.

This process can improve the material’s strength, ductility, and toughness.

9. What is the tempering process?

Tempering is a heat treatment process that involves heating a material to a high temperature and then rapidly cooling it.

This process can improve the material’s hardness and wear resistance.

10. What are the different types of heat treatment processes?

The following are the different types of heat treatment processes:

- Annealing

- Tempering

- Hardening

- Case hardening

- Nitriding

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Retort Furnace Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Retort Furnace Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Retort Furnace Helper is responsible for assisting in the operation and maintenance of a retort furnace. Key job responsibilities include:1. Furnace Operation

Assisting in the operation of retort furnaces, including loading, unloading, and monitoring the furnace temperature and atmosphere.

- Loading and unloading materials into and out of the furnace using proper handling equipment.

- Monitoring furnace temperature and atmosphere to ensure optimal conditions for the heat treatment process.

- Adjusting furnace settings as necessary to maintain the desired temperature and atmosphere.

2. Furnace Maintenance

Assisting in the maintenance of retort furnaces, including cleaning, inspection, and minor repairs.

- Cleaning the furnace chamber, burners, and other components to remove debris and ensure proper operation.

- Inspecting the furnace for any damage or wear and tear, and reporting any issues to the supervisor.

- Performing minor repairs, such as replacing gaskets or seals, under the guidance of a supervisor.

3. Material Handling

Handling materials used in the heat treatment process, including loading and unloading materials from racks and conveyors.

- Loading and unloading materials onto and off of racks and conveyors, using proper handling equipment.

- Ensuring that materials are properly placed in the furnace to maximize heat treatment efficiency.

- Inspecting materials for any damage or defects before loading them into the furnace.

4. Safety

Following all safety procedures and regulations, including wearing appropriate personal protective equipment and adhering to lockout/tagout procedures.

- Wearing personal protective equipment, such as gloves, safety glasses, and earplugs, as required.

- Adhering to lockout/tagout procedures to ensure that the furnace is properly isolated before performing maintenance or repairs.

- Reporting any safety hazards or concerns to the supervisor immediately.

Interview Tips

To ace an interview for a Retort Furnace Helper position, follow these interview tips:1. Research the Company and the Position

Before the interview, research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and the specific responsibilities of the role.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read online reviews and articles about the company to gain insights into their reputation and work environment.

- Review the job description carefully to identify the key requirements and responsibilities of the role.

2. Highlight Relevant Experience and Skills

During the interview, be sure to highlight your relevant experience and skills that meet the requirements of the job description. Quantify your accomplishments whenever possible.

- Describe your previous experience operating and maintaining furnaces, including the types of furnaces you worked with.

- Share examples of how you handled challenging situations related to furnace operation or maintenance.

- Mention any certifications or training you have in furnace operation or maintenance.

3. Emphasize Safety and Attention to Detail

Safety and attention to detail are crucial qualities for a Retort Furnace Helper. Emphasize your commitment to following safety procedures and your ability to perform tasks with precision.

- Describe your understanding of safety protocols and how you implement them in your work.

- Provide examples of how you have maintained accuracy and attention to detail in previous roles.

- Mention any training or experience you have in quality assurance or process improvement.

4. Prepare Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” Practice your answers to deliver them confidently and concisely.

- Craft a concise self-introduction that highlights your relevant skills and experience.

- Explain your interest in the role and how it aligns with your career goals.

- Identify your strengths and weaknesses, providing specific examples to support your claims.

5. Ask Informed Questions

At the end of the interview, ask informed questions to demonstrate your interest in the position and the company. This shows that you are engaged and eager to learn more.

- Ask about the company’s future plans or industry trends.

- Inquire about opportunities for professional development or advancement within the organization.

- Ask about the company’s safety record and any specific safety initiatives they have implemented.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Retort Furnace Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Retort Furnace Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.