Feeling lost in a sea of interview questions? Landed that dream interview for Retort Pre-Cooker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Retort Pre-Cooker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

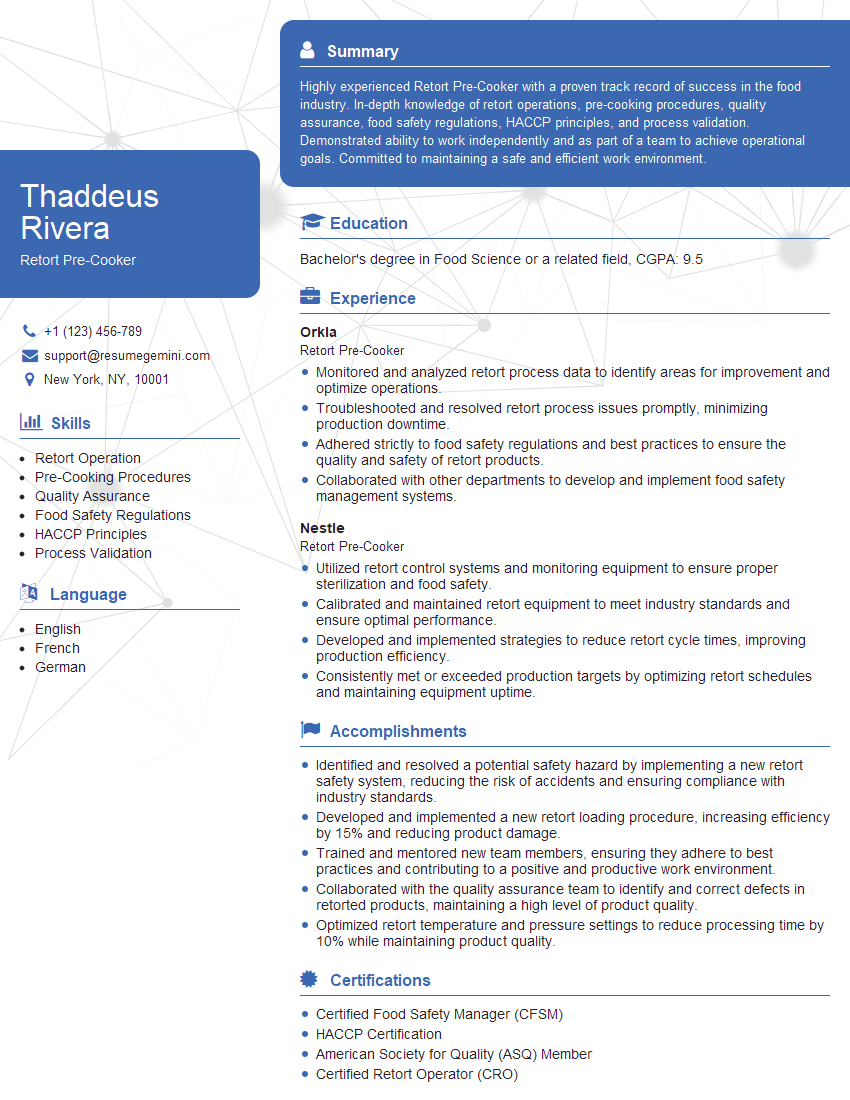

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Retort Pre-Cooker

1. Describe the process flow of retort pre-cooking?

The process flow of retort pre-cooking involves the following steps:

- Product preparation: Preparing the product for pre-cooking, which may involve cutting, slicing, or seasoning.

- Packaging: Filling pre-sterilized containers with the prepared product.

- Sealing: Hermetically sealing the containers to prevent contamination.

- Pre-cooking: Heating the sealed containers in a retort to a specific temperature and holding time to partially cook the product.

- Cooling: Rapidly cooling the pre-cooked containers to prevent overcooking and maintain quality.

- Storage: Storing the pre-cooked products under controlled conditions until further processing or distribution.

2. Explain the importance of temperature control during retort pre-cooking?

Accurate Heating

- Ensures uniform cooking and eliminates under or over-processing.

- Maintains product quality by controlling texture, color, and flavor.

Pathogen Control

- Eliminates harmful microorganisms by achieving and maintaining the required temperature and holding time for effective pasteurization.

- Prevents spoilage and ensures the safety of the pre-cooked product.

Process Optimization

- Optimizes pre-cooking time and temperature to achieve the desired level of doneness while minimizing energy consumption.

- Improves cost-effectiveness by reducing overcooking and waste.

3. What are the critical control points (CCPs) in retort pre-cooking and how are they monitored?

Critical control points (CCPs) in retort pre-cooking include:

- Container integrity: Ensuring the integrity of the containers to prevent leaks or contamination.

- Temperature control: Maintaining the required temperature and holding time throughout the pre-cooking process.

- Cooling rate: Controlling the cooling rate to prevent post-process spoilage and maintain product quality.

Monitoring methods:

- Container inspection: Visual inspection and pressure testing to check for defects.

- Temperature monitoring: Using temperature sensors and recorders to track the temperature throughout the pre-cooking process.

- Cooling rate measurement: Utilizing temperature probes or data loggers to monitor the cooling process.

4. Describe the role of pressure in retort pre-cooking?

- Increased heat transfer: Pressure increases the boiling point of water, allowing for higher cooking temperatures and faster heat penetration.

- Sterilization effectiveness: Higher temperatures under pressure facilitate more effective sterilization and pathogen reduction.

- Container integrity: Pressure helps maintain container integrity during pre-cooking, preventing container deformation or bursting.

- Product quality: Controlled pressure can contribute to improved product texture and color by minimizing overcooking.

5. Explain the difference between batch and continuous retort pre-cooking systems?

Batch Systems

- Process containers in batches, loaded and unloaded manually or semi-automatically.

- Suited for smaller production volumes and a wider range of container sizes and shapes.

Continuous Systems

- Continuously feed and discharge containers through the retort.

- Higher production capacity and automation, reducing labor costs.

- Typically used for larger production volumes and standardized container sizes.

6. What factors influence the selection of retort pre-cooking equipment?

- Production volume and capacity: Determining the required output and throughput.

- Container size and shape: Compatibility with the retort equipment and handling systems.

- Process requirements: Specific temperature, pressure, and holding time parameters.

- Cost and maintenance: Capital investment and ongoing operating expenses.

- Space constraints: Availability of floor space for equipment installation.

7. Describe the maintenance procedures for retort pre-cooking equipment?

- Regular cleaning and sanitation: To prevent contamination and ensure hygienic operation.

- Mechanical inspections: Checking for any loose parts, wear, or damage.

- Temperature and pressure calibration: Verifying the accuracy of sensors and gauges.

- Safety system testing: Ensuring proper functioning of alarms and interlocks.

- Record keeping: Documenting all maintenance activities for traceability and compliance.

8. Explain the importance of HACCP principles in retort pre-cooking?

- Hazard analysis: Identifying potential hazards associated with the pre-cooking process and raw materials.

- CCP determination: Establishing critical control points where hazards can be controlled or eliminated.

- Critical limit setting: Defining acceptable ranges for critical parameters such as temperature and time.

- Monitoring and verification: Regularly monitoring CCPs and verifying their effectiveness.

- Corrective actions: Implementing corrective measures when deviations occur to prevent or mitigate hazards.

9. Discuss the quality control measures for retort pre-cooked products?

- Sensory evaluation: Assessing the appearance, aroma, texture, and taste of the pre-cooked products.

- Microbiological testing: Conducting microbiological analyses to ensure the absence of harmful microorganisms.

- Chemical testing: Analyzing the pre-cooked products for nutrient content, pH, and other chemical parameters.

- Packaging inspection: Checking the integrity and quality of the packaging materials.

- Process validation: Verifying the effectiveness of the pre-cooking process through temperature and pressure monitoring.

10. What are the common challenges in retort pre-cooking and how can they be addressed?

Under or Over-Processing

- Challenge: Achieving the desired level of doneness while preventing overcooking.

- Solution: Accurate temperature control, monitoring, and process optimization.

Container Deformation

- Challenge: Maintaining container integrity during pre-cooking under pressure.

- Solution: Selecting appropriate containers, optimizing pressure settings, and using pressure-resistant materials.

Product Discoloration

- Challenge: Preventing color changes or darkening of the pre-cooked products.

- Solution: Controlling pre-cooking temperature and time, using antioxidants, and protective packaging.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Retort Pre-Cooker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Retort Pre-Cooker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Retort Pre-Cookers play a crucial role in the food processing industry, ensuring the safety and quality of canned foods. Their primary responsibilities encompass:

1. Pre-Cooking and Packaging Management

Preparing food products for retorting by conducting pre-cooking processes.

- Operating pre-cooking equipment to achieve desired product texture and moisture levels.

- Ensuring accurate filling and packaging of products into retortable pouches or containers.

2. Retort Operation and Monitoring

Operating and monitoring retort machines to sterilize pre-cooked products.

- Setting and maintaining retort parameters (temperature, pressure, and time) according to established protocols.

- Monitoring retort performance, troubleshooting any malfunctions, and maintaining records of processing conditions.

3. Quality Control and Inspection

Ensuring the quality and safety of pre-cooked products.

- Conducting organoleptic inspections to evaluate product appearance, texture, and flavor.

- Performing microbiological testing to monitor product sterility and shelf life.

4. Equipment Maintenance and Sanitation

Maintaining and cleaning equipment to ensure hygiene and optimal performance.

- Performing routine maintenance on pre-cooking and retort equipment to prevent breakdowns.

- Implementing sanitation procedures to prevent product contamination and maintain a clean work environment.

Interview Tips

To ace the interview for a Retort Pre-Cooker position, candidates should prepare thoroughly and showcase their relevant skills and experience. Here are some tips:

1. Research the Industry and Company

Demonstrate your knowledge of the food processing industry, including the role of retort pre-cooking. Research the company’s products and processes to understand their specific requirements.

2. Emphasize Your Technical Skills

Highlight your proficiency in pre-cooking techniques, retort operation, and quality control procedures. Quantify your experience whenever possible, using specific metrics and results.

3. Showcase Your Attention to Detail

Emphasize your meticulous nature and ability to follow protocols precisely. Explain how you ensure accuracy in pre-cooking, packaging, and retort operations.

4. Highlight Your Problem-Solving Abilities

Discuss your experience in troubleshooting retort equipment malfunctions and maintaining a hygienic work environment. Provide examples of how you have resolved issues and ensured product safety.

5. Prepare for Behavioral Questions

Be prepared to answer behavioral interview questions that explore your teamwork, communication, and work ethic. Use the STAR method (Situation, Task, Action, Result) to structure your responses and provide concrete examples.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Retort Pre-Cooker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Retort Pre-Cooker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.