Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Retort Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

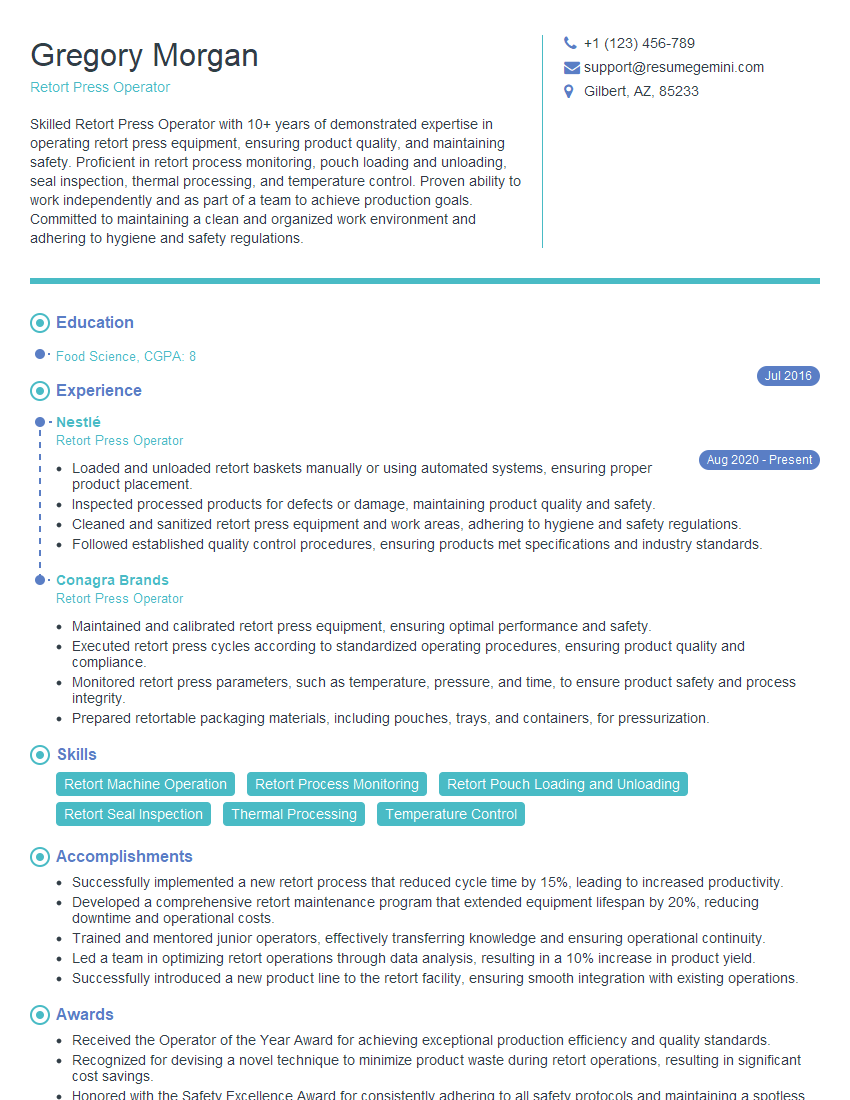

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Retort Press Operator

1. Describe the process of loading and unloading retorts?

Sample Answer

- Inspect the retort to ensure it is clean and in good working condition.

- Load the retort with the product to be sterilized, following the prescribed loading pattern.

- Secure the retort door and seal it according to the manufacturer’s instructions.

- Unload the retort once the sterilization process is complete, taking precautions to avoid spills or contamination.

2. How do you maintain and calibrate retort equipment?

Daily Maintenance

- Inspect the retort for any leaks or damage.

- Check the temperature and pressure gauges for accuracy.

- Lubricate moving parts as per manufacturer’s recommendations.

Monthly Maintenance

- Calibrate the retort temperature and pressure gauges.

- Inspect the safety valves and relief devices.

- Clean and inspect the retort chamber and door seals.

3. What are the different types of retort processes and their applications?

Sample Answer

- Still Retort Process: Used for low-acid foods in flexible or semi-rigid containers.

- Agitating Retort Process: Used for viscous or particulate foods that require agitation during sterilization.

- Hydrostatic Retort Process: Uses water as the heating medium, providing uniform heat distribution.

- Overpressure Retort Process: Maintains a higher pressure inside the retort, reducing processing time.

4. How do you troubleshoot common retort issues?

Sample Answer

- Retort not heating properly: Check the heating elements, temperature probe, and control system.

- Retort leaking: Inspect the door seals, gaskets, and piping for damage or leaks.

- Pressure not building up: Check the pressure gauge, safety valves, and air supply.

- Product contamination: Determine the source of contamination and take corrective actions such as cleaning or replacing seals.

5. What are the safety precautions to observe while operating a retort?

Sample Answer

- Wear proper personal protective equipment (PPE).

- Inspect the retort before each use and follow all safety protocols.

- Never open the retort door until the pressure has fully dissipated.

- Handle hot products with caution and use insulated gloves or tongs.

- Report any malfunctions or safety concerns immediately.

6. Describe the importance of recordkeeping in retort operations?

Sample Answer

- Quality Assurance: Records provide evidence of proper sterilization and compliance with regulatory requirements.

- Traceability: In the event of a product recall, records allow for quick identification and isolation of affected products.

- Process Optimization: Records can be analyzed to identify areas for improvement and optimize retort processes.

- Legal Compliance: Accurate records are essential for meeting regulatory standards and defending against potential legal claims.

7. How do you ensure the accuracy of retort temperature and pressure readings?

Sample Answer

- Calibration: Regularly calibrate temperature and pressure gauges using certified equipment.

- Verification: Compare readings from multiple gauges or use independent temperature and pressure monitoring devices to verify accuracy.

- Maintenance: Keep gauges clean and free from damage. Inspect and replace them as necessary.

- Training: Train operators on the proper use and interpretation of temperature and pressure readings.

8. What are the potential hazards associated with retort operations and how do you mitigate them?

Sample Answer

- Explosion: Ensure proper ventilation, follow pressure limits, and maintain equipment in good condition.

- Burns: Wear heat-resistant clothing, use insulated gloves, and handle hot products with caution.

- Chemical exposure: Wear appropriate respiratory protection when handling chemicals used in retort operations.

- Ergonomic hazards: Implement proper lifting techniques and use mechanical aids to reduce strain.

9. Describe the role of automation in modern retort operations.

Sample Answer

- Process Control: Automated systems monitor and adjust temperature, pressure, and other parameters to ensure consistent sterilization.

- Data Collection: Automation records and stores process data, facilitating quality control and traceability.

- Safety Enhancements: Automated systems can implement safety features such as automatic shut-offs and alarms.

- Increased Efficiency: Automation reduces manual labor, improves productivity, and minimizes downtime.

10. Discuss the importance of continuous improvement in retort operations.

Sample Answer

- Process Optimization: Regularly review and evaluate retort processes to identify areas for improvement and enhance efficiency.

- Safety Enhancements: Continuously seek ways to improve safety measures and reduce potential hazards.

- Cost Reduction: Implement innovative techniques to reduce operating costs while maintaining product quality.

- Compliance with Regulations: Stay updated with industry standards and regulatory changes to ensure compliance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Retort Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Retort Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Retort Press Operator is responsible for the operation and maintenance of retort press equipment, used in the production of canned food items. Their main task is to ensure that the food products are safely and efficiently processed, meeting all regulatory and quality standards.

1. Equipment Operation

Primary responsibility involves operating retort press equipment, including loading, unloading, and monitoring the retort process.

- Follow established operating procedures and safety protocols.

- Load and unload product containers into and out of the retort.

2. Process Monitoring and Control

Monitor and control the retort process parameters, such as temperature, pressure, and time, to ensure product safety and quality.

- Check and adjust retort parameters according to established specifications.

- Record and document all process data.

3. Quality Assurance

Conduct quality checks on processed products to ensure they meet specifications and are safe for consumption.

- Inspect product containers for defects or damage.

- Perform organoleptic tests to assess product quality.

4. Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting on retort press equipment to ensure optimal performance.

- Clean and lubricate equipment.

- Identify and resolve equipment malfunctions.

Interview Preparation Tips

Preparing thoroughly for a Retort Press Operator interview is crucial to present yourself as a confident and qualified candidate. Here are some tips to enhance your chances of success.

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and values. Research industry trends and regulations related to food processing.

2. Practice Common Interview Questions

Prepare for common interview questions related to your experience in retort press operation, quality control, and safety practices.

3. Highlight Relevant Skills and Experience

In your resume and interview, emphasize your skills in operating retort press equipment, monitoring process parameters, and conducting quality checks.

4. Showcase Your Attention to Detail

Retort Press Operators must be meticulous and attentive to detail. Highlight instances where you have demonstrated strong observational abilities and accuracy in your work.

5. Convey Your Safety Consciousness

Food safety is paramount in this role. Express your understanding of safety protocols and your commitment to maintaining a safe work environment.

6. Demonstrate Your Problem-Solving Skills

Retort press operation can involve troubleshooting. Discuss situations where you have successfully identified and resolved equipment issues.

7. Be Prepared to Discuss Quality Standards

Emphasize your knowledge of food safety regulations and your commitment to meeting or exceeding quality standards.

8. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately and arrive on time for your interview to demonstrate your professionalism.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Retort Press Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.