Are you gearing up for an interview for a Retread Builder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Retread Builder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

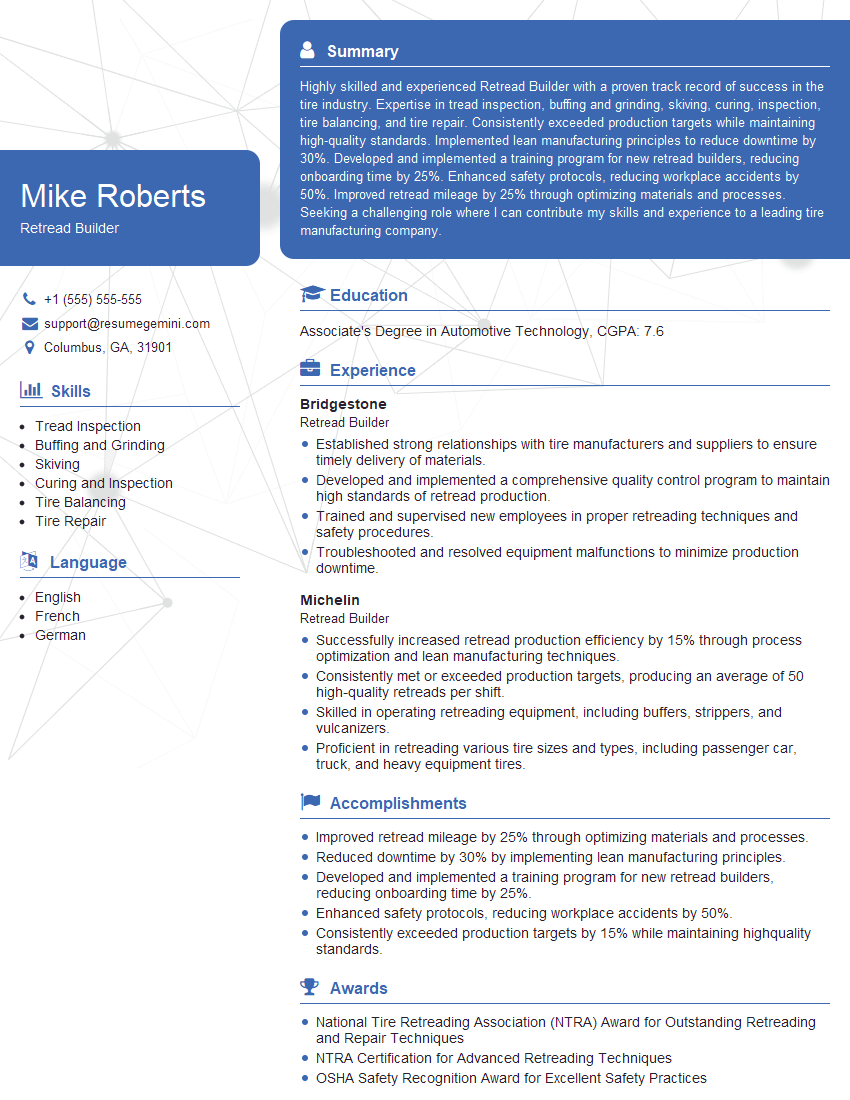

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Retread Builder

1. What are the key steps involved in the retread building process?

The key steps involved in the retread building process include:

- Inspection and preparation of the casing

- Buffing or grinding the casing to remove old tread

- Applying cement to the casing

- Wrapping the casing with new tread material

- Curing the retread in a mold

- Inspecting and testing the finished retread

2. What are the different types of retread materials available?

The different types of retread materials available include:

Natural Rubber

- Provides good traction and flexibility

- Less resistant to wear and tear than synthetic rubber

Synthetic Rubber

- More resistant to wear and tear than natural rubber

- May have lower traction and flexibility

Precure Tread

- Made from pre-vulcanized rubber

- Applied as a sheet to the casing

Camelback Tread

- Made from uncured rubber

- Applied to the casing and then vulcanized

3. What are the advantages and disadvantages of using precure tread versus camelback tread?

Advantages of precure tread:

- Faster and easier to apply

- Lower risk of defects

- More consistent quality

Disadvantages of precure tread:

- More expensive than camelback tread

- May have lower traction than camelback tread

Advantages of camelback tread:

- Less expensive than precure tread

- May have better traction than precure tread

- Can be customized to specific requirements

Disadvantages of camelback tread:

- More time-consuming and difficult to apply

- Higher risk of defects

- May have less consistent quality

4. What are the common defects that can occur during the retread building process?

The common defects that can occur during the retread building process include:

- Tread separation

- Blisters

- Cracks

- Porosity

- Uneven wear

These defects can be caused by a variety of factors, including improper preparation of the casing, incorrect application of materials, and inadequate curing.

5. How do you ensure the quality of retreaded tires?

To ensure the quality of retreaded tires, it is important to follow proper building procedures and conduct thorough inspections at each stage of the process. This includes:

- Inspecting the casing for damage

- Properly preparing the casing

- Applying the correct amount of cement

- Wrapping the casing with the correct tension

- Curing the retread at the correct temperature and pressure

- Inspecting the finished retread for defects

In addition to following proper procedures, it is also important to use high-quality materials and equipment.

6. What is the average lifespan of a retreaded tire compared to a new tire?

The average lifespan of a retreaded tire compared to a new tire depends on several factors, including the quality of the workmanship, the type of tire, and the operating conditions. However, in general, a well-made retreaded tire can last 70-80% as long as a new tire.

7. What are the environmental benefits of retreading tires?

Retreading tires has a number of environmental benefits, including:

- Reduces the number of tires that end up in landfills

- Conserves natural resources, such as rubber and oil

- Reduces greenhouse gas emissions

Retreading tires is a more sustainable option than replacing them with new tires, and it can help to reduce our environmental impact.

8. What are the safety considerations when using retreaded tires?

Retreaded tires are generally safe to use, but there are some safety considerations that should be kept in mind:

- Ensure that the retreaded tires are properly inspected and meet all safety standards

- Avoid using retreaded tires on critical applications, such as steering or braking

- Monitor the retreaded tires regularly for any signs of wear or damage

By following these safety considerations, you can help to ensure that retreaded tires are used safely and effectively.

9. What are the latest trends in retread technology?

The latest trends in retread technology include:

- The development of new and improved tread compounds

- The use of advanced manufacturing techniques

- The increasing use of retreaded tires on commercial vehicles

These trends are helping to make retreaded tires more durable, efficient, and cost-effective.

10. What are the future prospects for the retread industry?

The future prospects for the retread industry are positive. The increasing demand for sustainable and cost-effective tire solutions is driving growth in the retread market. Additionally, advancements in retread technology are making retreaded tires more comparable to new tires in terms of performance and safety.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Retread Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Retread Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Retread Builders are technicians who specialize in rebuilding commercial and industrial tires to make them reusable. They are responsible for various critical tasks within tire manufacturing facilities, ensuring optimum tire performance and safety.

1. Tire Inspection and Assessment

Inspect tires thoroughly to evaluate their condition, identify damages, and determine whether they are suitable for retreading.

- Inspect tire tread depth, sidewalls, and beads for any abnormalities, wear, or damage.

- Assess the extent of damage and determine the feasibility of retreading based on repair criteria.

2. Tire Preparation

Prepare tires for the retreading process by removing all previous tread, reinforcing materials, and other components.

- Use specialized equipment like buffers and grinders to remove old tread effectively.

- Clean and inspect the tire casing to ensure it meets retreading standards.

3. Tread Application

Apply new tread to the prepared tire casing using specialized tire building equipment.

- Select the appropriate tread pattern and design based on tire specifications.

- Accurately position and adhere the new tread to the tire casing according to manufacturer guidelines.

4. Curing and Finishing

Cure the rebuilt tire under controlled pressure and temperature to ensure proper bonding and durability.

- Monitor curing cycles and adjust parameters to achieve optimal tire performance.

- Inspect the finished tires for any defects or imperfections.

5. Quality Assurance

Conduct quality checks throughout the retreading process to ensure product quality and adherence to industry standards.

- Perform visual inspections, measure tread depth, and check for any potential issues.

- Maintain detailed records of retreading operations for traceability and accountability.

Interview Tips

Preparing thoroughly for a Retread Builder interview is essential to increase your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Industry

Research the company you’re applying to, including their history, values, and current projects. Understanding their business operations and the industry’s trends will demonstrate your interest and enthusiasm.

- Visit the company’s website to learn about their mission, services, and recent developments.

- Read industry publications and news articles to stay informed about the latest technologies and best practices.

2. Practice Your Answers to Common Interview Questions

Prepare for typical interview questions by practicing your responses. Focus on highlighting your skills, experience, and how they align with the job requirements. Consider using the STAR method to structure your answers.

- Example Outline:

- Situation: Provide a specific situation or task that relates to the question.

- Task: Describe the task or responsibility you were accountable for.

- Action: Explain the actions you took to complete the task.

- Result: Quantify the results or positive outcomes of your actions.

3. Emphasize Your Technical Skills and Knowledge

As a Retread Builder, your technical abilities are crucial. In the interview, highlight your expertise in tire inspection, preparation, tread application, curing, and quality assurance. Provide specific examples of your accomplishments in these areas.

- Quantify your performance whenever possible, such as reducing retreading time or improving tire quality.

- Mention any certifications or training programs you’ve completed to enhance your knowledge and skills.

4. Prepare Questions for the Interviewer

Preparing thoughtful questions for the interviewer shows your engagement and interest in the role. Ask questions about the company’s retreading processes, safety protocols, and industry best practices.

- Example Questions:

- What are the key quality control measures implemented during the retreading process?

- How does the company stay updated with the latest advancements in tire retreading technology?

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally for the interview and arrive on time. Respecting the interviewer’s time and showing professionalism will create a positive impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Retread Builder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!