Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Retread Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

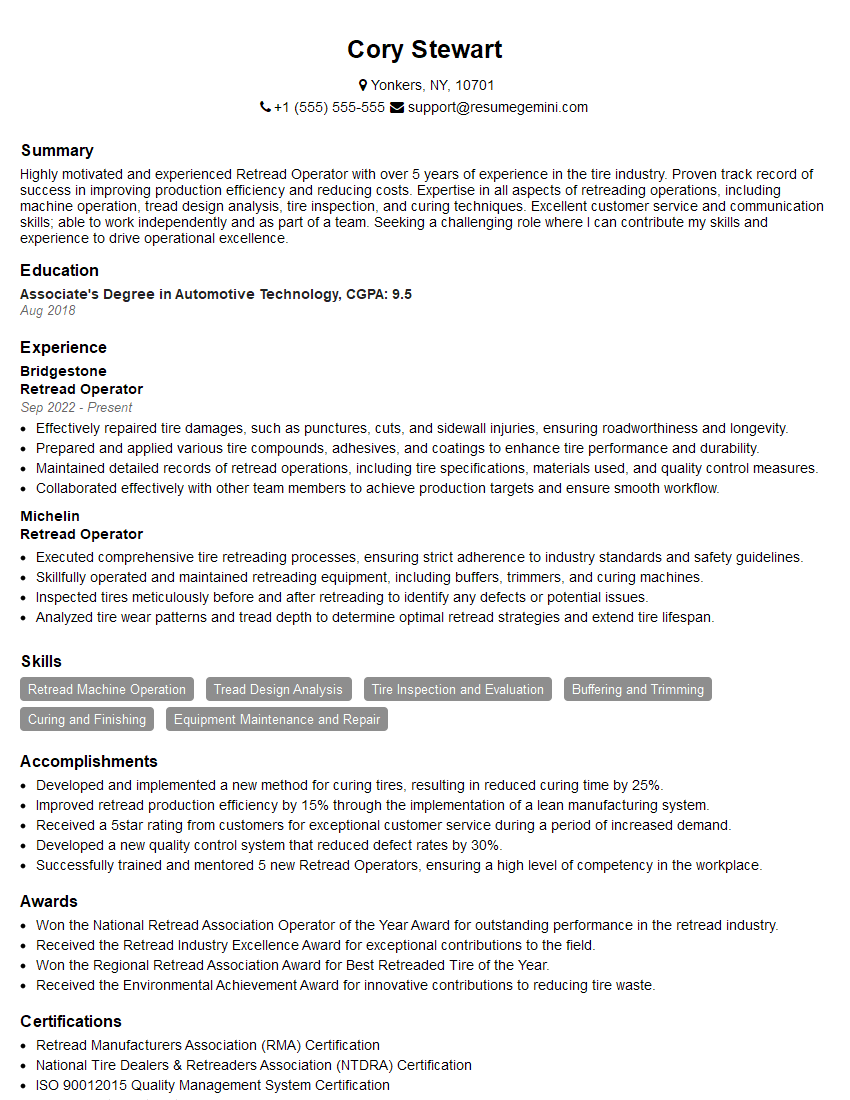

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Retread Operator

1. Can you briefly explain the vulcanization process used in retreading tires?

Vulcanization is a process that converts natural rubber into a more durable and elastic material by cross-linking the polymer chains with sulfur.

- It involves heating the tire casing with uncured rubber and sulfur under high pressure.

- This process strengthens the bonds between the rubber molecules, resulting in increased durability and resistance to wear.

2. How do you ensure the quality of retreaded tires?

Ensuring the quality of retreaded tires involves several key steps:

- Thorough inspection: The tire casing is carefully examined for any damage or defects that could compromise the retreading process.

- Proper preparation: The casing is buffed to remove any old tread or damage, and then thoroughly cleaned to ensure a strong bond with the new rubber.

- High-quality materials: Using premium-grade rubber compounds and adhesives is crucial for ensuring the durability and performance of the retreaded tire.

- Precision equipment: Advanced machinery and techniques are employed to apply the new tread and ensure proper bonding and curing.

- Rigorous testing: Retreaded tires undergo rigorous testing to meet safety and performance standards, including inflation tests, endurance tests, and visual inspections.

3. What types of tire damage can be repaired during retreading, and which cannot?

Repairable damage:

- Punctures and cuts in the tread area

- Minor sidewall damage

- Belt separations

Unrepairable damage:

- Structural damage to the tire casing

- Severe sidewall damage

- Cord damage

- Tire bead damage

4. What are the advantages and disadvantages of retreading tires?

Advantages:

- Cost-effective: Retreading is significantly cheaper than purchasing new tires.

- Environmentally friendly: Retreading reduces waste and conserves natural resources.

- Extended tire life: Retreading can extend the lifespan of a tire by several thousand kilometers.

- Improved safety: Retreaded tires must meet the same safety standards as new tires.

Disadvantages:

- Potential performance limitations: Retreaded tires may not offer the same performance as new tires in certain conditions.

- Suitability limitations: Not all tires are suitable for retreading.

- Availability issues: Retreading may not be readily available in all areas.

5. How do you determine when a tire is suitable for retreading?

Determining the suitability of a tire for retreading involves evaluating several factors:

- Tread depth: The remaining tread depth must meet the minimum specifications for retreading.

- Casing condition: The tire casing must be free of any major damage or defects.

- Tire size and type: Not all tire sizes and types are suitable for retreading.

- Retreadability index: Some tire manufacturers provide a retreadability index to indicate the tire’s suitability for retreading.

6. Can you describe the different types of retreading methods?

- Hot retreading: Involves applying uncured rubber to the tire casing and curing it under heat and pressure.

- Pre-cure retreading: Uses pre-cured tread strips that are bonded to the tire casing using adhesives.

- Mold cure retreading: Employs a mold to shape and cure the new tread on the tire casing.

7. What are the key safety considerations when operating a retread machine?

- Proper training and authorization: Only trained and authorized personnel should operate retread machines.

- Safe operating procedures: Adhering to established safety protocols and guidelines is crucial.

- Protective gear: Wearing appropriate protective gear, such as gloves and safety glasses, is essential.

- Machine maintenance: Regular inspection and maintenance of the retread machine are necessary to ensure its safe operation.

- Hazard awareness: Being aware of potential hazards, such as hot surfaces and moving parts, is essential for preventing accidents.

8. How do you handle and store retreaded tires before and after processing?

- Before processing: Tires should be stored in a cool, dry place to prevent damage.

- During processing: Tires should be handled carefully to avoid damage and contamination.

- After processing: Retreaded tires should be cured and cooled properly before storage.

- Long-term storage: Retreaded tires should be stored in a controlled environment to maintain their quality.

9. What are the common problems that can occur during the retreading process, and how do you address them?

- Tread separation: Improper bonding between the new tread and the tire casing can lead to tread separation. This can be addressed by ensuring proper surface preparation, using high-quality adhesives, and following correct curing procedures.

- Casing damage: Damage to the tire casing during retreading can compromise the tire’s integrity. This can be avoided by careful handling and proper inspection before and during the process.

- Porosity: Air bubbles trapped in the new tread can weaken it. This can be minimized by using vacuum degassing techniques and proper curing.

10. How do you stay up-to-date with the latest retreading technologies and best practices?

- Industry conferences and trade shows: Attending industry events allows for networking and learning about new technologies.

- Technical publications and online resources: Reading trade magazines and accessing online forums provides valuable information.

- Manufacturer training programs: Participating in manufacturer-led training programs ensures knowledge of the latest techniques.

- Collaboration with peers: Exchanging ideas and experiences with other retread operators can foster knowledge sharing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Retread Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Retread Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Retread Operators play a crucial role in the tire manufacturing process, responsible for ensuring the quality and durability of retreaded tires. Their responsibilities encompass:

1. Tire Preparation

Inspect and prepare casings for retreading by removing old tread, nails, and other debris using specialized equipment.

- Buff the casing to create a smooth surface for bonding.

- Apply primer and cushion gum to prepare the casing for new tread.

2. Tread Application

Apply new tread to the prepared casing using a tire-building machine.

- Monitor the tread application process to ensure proper alignment and bonding.

- Inspect the applied tread for any defects or imperfections.

3. Curing and Finishing

Place the retreaded tire in a curing chamber to vulcanize the tread and casing.

- Monitor the curing process to ensure optimal bonding and quality.

- Perform final inspections and touch-ups on the retreaded tires.

4. Quality Control

Adhere to strict quality control standards to ensure the safety and performance of the retreaded tires.

- Inspect tires for any defects or irregularities.

- Maintain accurate records of inspections and tire performance.

Interview Tips

Preparation is the key to a successful interview. Here are some tips to help you ace your Retread Operator interview:

1. Research the Company and Industry

Take the time to learn about the company’s history, values, and current projects. Research the tire retreading industry to demonstrate your understanding of the field.

- Visit the company website and read industry publications.

- Identify the key trends and challenges in the tire retreading sector.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers aloud. Focus on highlighting your skills, experience, and passion for tire retreading.

- Develop a strong answer to the question, “Why are you interested in becoming a Retread Operator?”

- Explain your understanding of the retreading process and how you can contribute to the company’s operations.

3. Showcase Your Technical Expertise

Emphasize your knowledge of tire construction, retreading equipment, and quality control procedures.

- Discuss your experience with tire inspection, repair, and maintenance.

- Provide examples of your attention to detail and commitment to safety.

4. Highlight Your Problem-Solving Skills

Retread Operators often face challenges on the job. Highlight your ability to identify and resolve problems efficiently.

- Share examples of how you have solved problems in previous roles.

- Explain how you approach troubleshooting and finding solutions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Retread Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!