Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Retreader position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

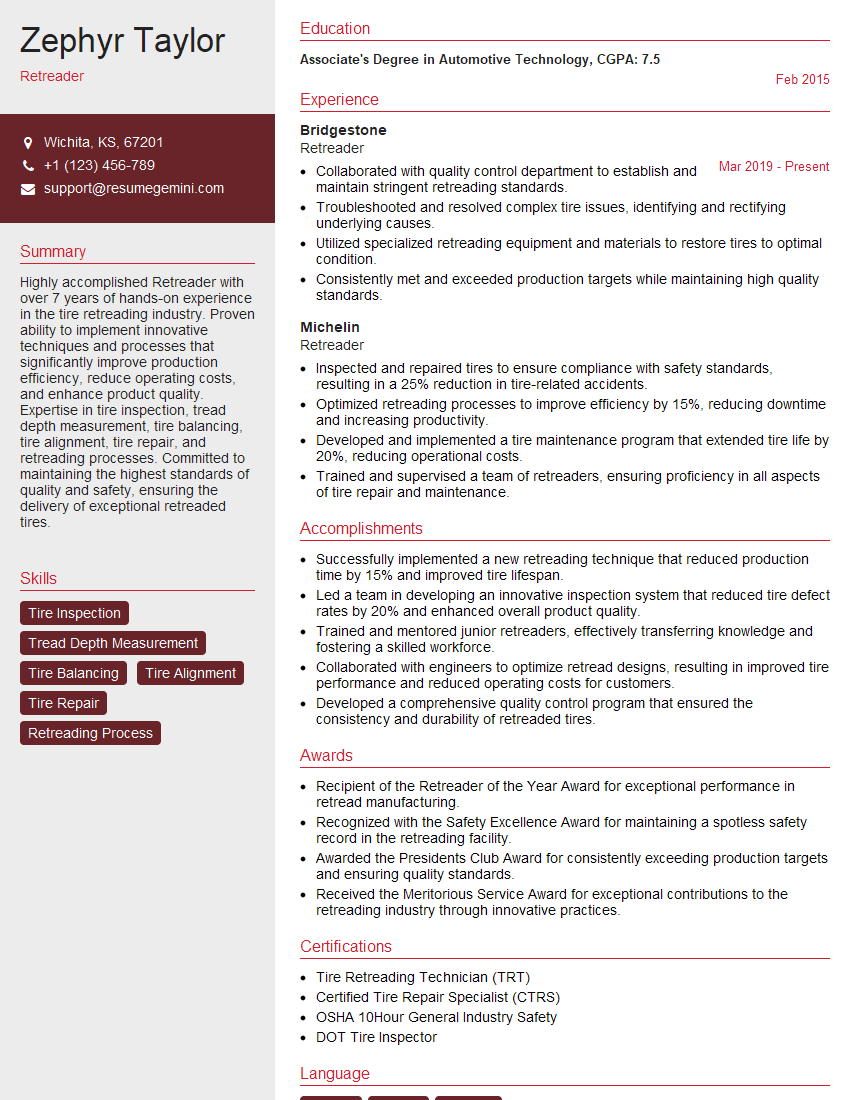

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Retreader

1. Tell us about your experience in retreading tires, and what are the different types of retreading processes you are familiar with?

In my previous role as a Retreader, I was responsible for retreading a wide range of tire sizes and types, including passenger car, truck, and off-road tires. I am familiar with both hot and cold retreading processes, as well as pre-cured and mold-cure methods.

2. What are the key quality control checks you perform during the retreading process?

Visual Inspection

- Inspecting the tire for any signs of damage, such as cuts, punctures, or bulges.

- Checking the tread depth and wear pattern.

Dimensional Checks

- Measuring the tire’s diameter, width, and circumference to ensure it meets specifications.

- Checking the tire’s runout and balance.

3. How do you select the appropriate retreading materials for different tire applications?

The selection of retreading materials depends on several factors, including the type of tire, the intended use, and the operating conditions. Some of the key considerations include:

- Tread compound: The tread compound should be selected based on the tire’s intended use, such as highway, off-road, or winter conditions.

- Casing: The casing should be inspected for any damage and repaired or replaced as necessary.

- Bead: The bead should be checked for any damage or corrosion and repaired or replaced as necessary.

4. What are the common defects that can occur during the retreading process, and how do you prevent them?

Some of the common defects that can occur during the retreading process include:

- Tread separation: This can occur if the tread is not properly bonded to the casing.

- Bead failure: This can occur if the bead is not properly seated or if the casing is damaged.

- Sidewall damage: This can occur if the tire is subjected to excessive stress or if it is not properly handled.

5. How do you stay up-to-date on the latest retreading techniques and industry best practices?

I stay up-to-date on the latest retreading techniques and industry best practices by:

- Attending industry conferences and workshops.

- Reading trade publications and technical journals.

- Consulting with experts in the field.

6. What are the safety precautions you take when working with retreading equipment and materials?

When working with retreading equipment and materials, I take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator.

- Follow all manufacturer’s instructions for the safe operation of equipment.

- Handle materials carefully to avoid spills or accidents.

7. How do you ensure the quality of your retreaded tires?

I ensure the quality of my retreaded tires by:

- Following all industry standards and best practices.

- Using high-quality materials and equipment.

- Performing rigorous quality control checks throughout the retreading process.

8. What are the environmental regulations that apply to retreading operations, and how do you comply with them?

The environmental regulations that apply to retreading operations include:

- The Resource Conservation and Recovery Act (RCRA).

- The Clean Air Act (CAA).

- The Clean Water Act (CWA).

9. What is your approach to customer service, and how do you handle customer complaints and inquiries?

I believe that customer service is essential to any business. I am always willing to go the extra mile to help my customers, and I am always available to answer their questions or concerns. I handle customer complaints and inquiries promptly and professionally, and I always try to resolve them to the customer’s satisfaction.

10. What are your career goals, and how do you see this role contributing to your professional development?

My career goal is to become a leader in the retreading industry. I am confident that this role will provide me with the opportunity to learn from experienced professionals and to develop my skills and knowledge. I am eager to take on new challenges and responsibilities, and I am confident that I can make a significant contribution to your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Retreader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Retreader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Retreader plays a crucial role in the tire industry, carrying out specialized tasks to restore used tires and extend their lifespan. The key responsibilities of a Retreader include:

1. Tire Inspection

Thoroughly examining used tires to identify any damages, defects, or areas of wear. Determining if tires are suitable for retreading or require further assessment.

2. Tire Preparation

Preparing tires for retreading by removing old tread, buffing the casing, and inspecting the inner liner to ensure no damage or leaks.

3. Tread Application

Applying new tread rubber to the prepared tire casing using specialized equipment and techniques to create a durable and long-lasting surface.

4. Curing and Inspection

Curing the re-treaded tire using heat and pressure to bond the new tread to the casing. Conducting final inspections to verify the quality and safety of the finished tire.

5. Record Keeping

Maintaining accurate records of each tire retreaded, including the tire’s specifications, inspection results, and any repairs or modifications.

Interview Tips

Preparing for a Retreader interview will significantly enhance your chances of success. Here are some tips to prepare effectively:

1. Research the Company and Industry

Familiarize yourself with the company’s history, services, and recent developments. Learn about the specific equipment and techniques used in the tire retreading industry to demonstrate your interest and knowledge.

2. Practice Your Answers

Anticipate common interview questions related to your skills, experience, and motivation. Rehearse your answers to highlight your strengths, relevant accomplishments, and why you are a suitable candidate for the position.

3. Emphasize Safety and Quality

Retreading involves handling heavy equipment and hazardous materials. Emphasize your commitment to safety and maintaining the highest quality standards in your work. Highlight any training or certifications that support this.

4. Show Passion for the Industry

Convey your genuine interest in the tire retreading industry and its importance in reducing waste and promoting sustainability. Explain how this passion drives you to excel in your role.

5. Be Prepared to Discuss Technical Details

Be ready to discuss the technical aspects of retreading, such as different tread designs, casing evaluation techniques, and quality control processes. This shows your understanding of the job and ability to contribute effectively.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Retreader interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!