Feeling lost in a sea of interview questions? Landed that dream interview for Reverberatory Furnace Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Reverberatory Furnace Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

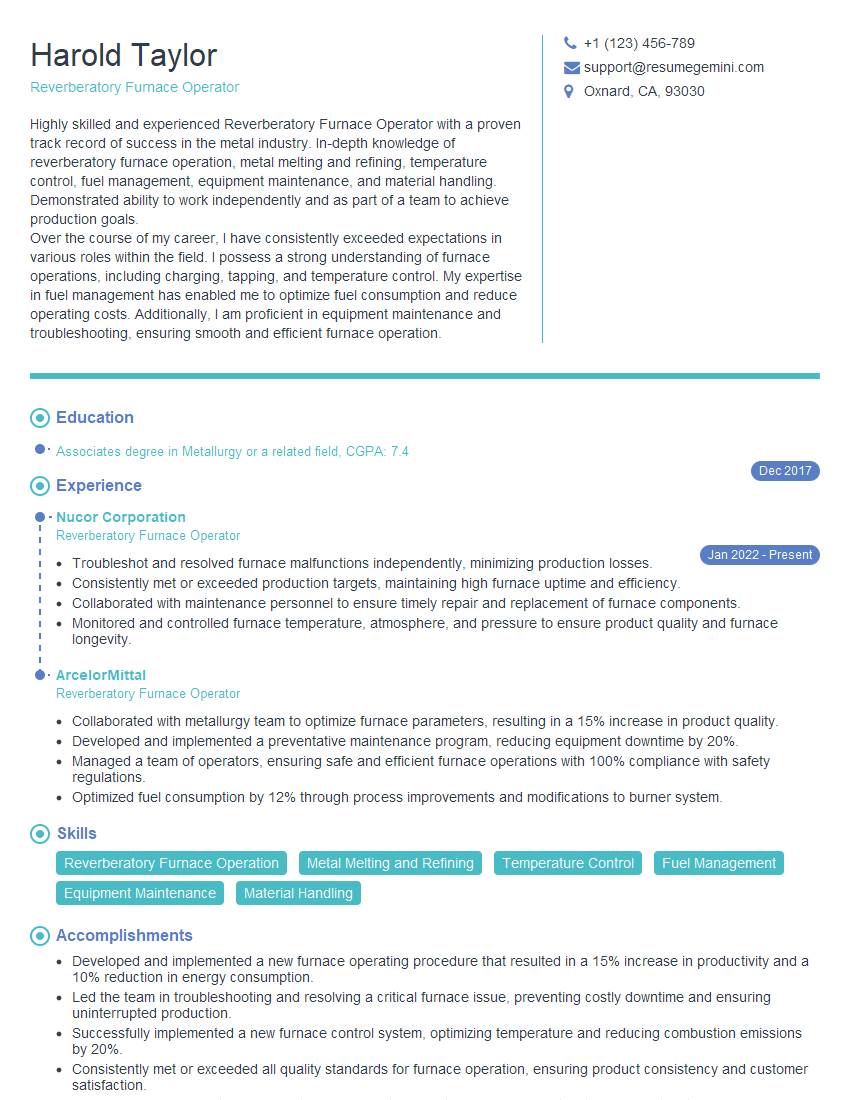

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reverberatory Furnace Operator

1. What are the key responsibilities of a Reverberatory Furnace Operator?

- Operate and maintain the reverberatory furnace

- Monitor and control the furnace temperature

- Charge and discharge the furnace

- Control the flow of air and fuel to the furnace

- Maintain the furnace in good working condition

2. What are the different types of fuel that can be used in a reverberatory furnace?

- Natural gas

- Oil

- Coal

- Electricity

3. What are the safety procedures that must be followed when operating a reverberatory furnace?

- Wear appropriate personal protective equipment

- Be aware of the location of the fire extinguishers and know how to use them

- Never enter the furnace without authorization

- Be aware of the potential for explosions

- Follow all safety rules and procedures

4. What are the most common problems that can occur with a reverberatory furnace?

- Burners can become clogged

- The furnace can overheat

- The furnace can develop leaks

- The refractory lining can become damaged

- The furnace can shut down unexpectedly

5. How do you troubleshoot a reverberatory furnace that is not operating properly?

- Check the burners for clogs

- Check the furnace temperature

- Inspect the furnace for leaks

- Inspect the refractory lining

- Check the electrical connections

- Refer to the manufacturer’s manual for troubleshooting tips

6. What are the key performance indicators for a Reverberatory Furnace Operator?

- Furnace uptime

- Furnace productivity

- Furnace efficiency

- Furnace quality

- Furnace safety

7. What are the different types of materials that can be processed in a reverberatory furnace?

- Metals

- Glass

- Ceramics

- Chemicals

- Food

8. What are the advantages of using a reverberatory furnace?

- Reverberatory furnaces are very efficient

- Reverberatory furnaces can be used to process a wide variety of materials

- Reverberatory furnaces are relatively easy to operate

- Reverberatory furnaces are relatively inexpensive to purchase and maintain

9. What are the disadvantages of using a reverberatory furnace?

- Reverberatory furnaces can be large and bulky

- Reverberatory furnaces can be slow to heat up and cool down

- Reverberatory furnaces can be difficult to control

- Reverberatory furnaces can be dangerous to operate

10. What are the future trends in reverberatory furnace technology?

- Reverberatory furnaces are becoming more efficient

- Reverberatory furnaces are becoming more automated

- Reverberatory furnaces are becoming more environmentally friendly

- Reverberatory furnaces are becoming more cost-effective

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reverberatory Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reverberatory Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Reverberatory Furnace Operator is responsible for the safe and efficient operation of a reverberatory furnace, used in various industries such as metalworking, glassmaking, and ceramics production.

1. Furnace Operation

Manage and control the furnace’s temperature, pressure, and fuel flow to maintain optimal operating conditions.

- Monitor and adjust fuel-air mixtures to ensure proper combustion.

- Supervise furnace cleaning and maintenance to ensure efficient operation.

2. Material Handling

Load and unload materials into and from the furnace, ensuring proper charging and tapping techniques.

- Control the flow of molten materials using refractory materials and equipment.

- Maintain proper material inventory and monitor product quality.

3. Safety and Maintenance

Adhere to safety regulations and protocols to ensure a safe work environment.

- Inspect and maintain furnace equipment, identifying and resolving potential issues.

- Troubleshoot and resolve furnace malfunctions promptly.

4. Production Monitoring

Monitor production processes and collect data to ensure quality and efficiency.

- Analyze furnace performance and suggest improvements to optimize production.

- Maintain records and documentation related to furnace operation and production.

Interview Tips

Interview preparation for a Reverberatory Furnace Operator position requires a solid understanding of the role’s responsibilities and technical aspects, as well as effective communication and problem-solving skills.

1. Research the Company and Position

Learn about the company’s industry, products, and specific requirements for the Reverberatory Furnace Operator role.

- Visit the company’s website and read industry publications to gain insights.

- Review the job description thoroughly to identify the key skills and responsibilities expected.

2. Highlight Relevant Experience

Emphasize your past experience in furnace operation, material handling, and safety protocols.

- Provide specific examples of your responsibilities and accomplishments in previous roles.

- Quantify your achievements using metrics whenever possible.

3. Demonstrate Technical Proficiency

Showcase your knowledge of reverberatory furnace principles, fuel combustion, and refractory materials.

- Explain the combustion process and how you control it to achieve optimal operating conditions.

- Describe the properties and uses of different refractory materials.

4. Emphasize Safety and Problem-Solving

Highlight your commitment to safety and your ability to troubleshoot and resolve furnace issues effectively.

- Discuss your understanding of safety regulations and your role in maintaining a safe work environment.

- Provide examples of how you have identified and resolved furnace malfunctions in the past.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Reverberatory Furnace Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.