Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rewinder Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

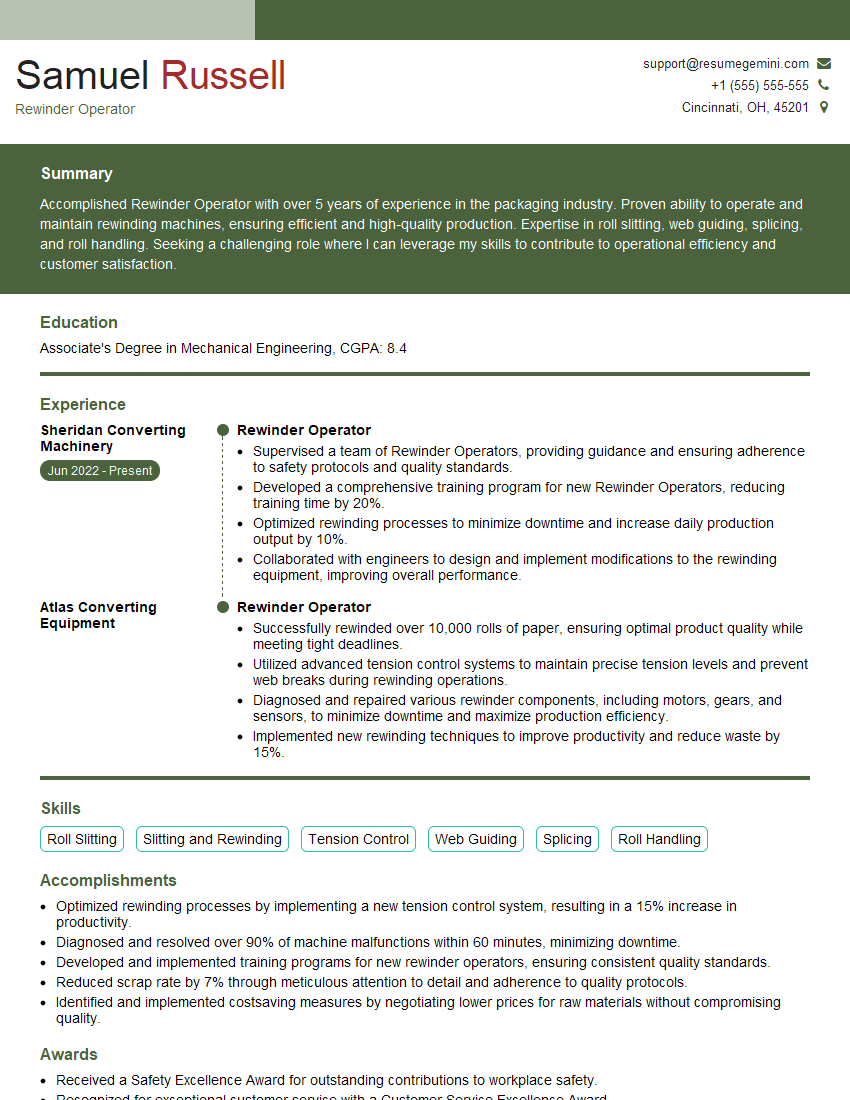

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rewinder Operator

1. How do you maintain and calibrate a rewinding machine?

To maintain and calibrate a rewinding machine, I follow a comprehensive procedure that ensures optimal performance and accuracy.

- Daily Checks: I perform routine checks on key components, including the spindle, tension control system, and web guide, to identify any issues early on.

- Regular Cleaning and Lubrication: I meticulously clean and lubricate all moving parts to prevent wear and tear, ensuring smooth operation and extending the machine’s life.

2. What techniques do you employ to minimize waste and maximize roll quality during the rewinding process?

Efficient Core Loading

- Properly align the core on the spindle to ensure even winding and prevent core damage.

- Use the appropriate core size for the material being wound to optimize roll stability.

Precision Tension Control

- Calibrate the tension control system to maintain consistent tension throughout the roll, preventing wrinkles and defects.

- Monitor tension levels during the process and make adjustments as needed.

3. Describe the types of materials you have experience rewinding and the specific techniques required for each.

I have experience rewinding a wide range of materials, including:

- Paper and Board: These materials require careful handling to avoid tearing or creasing. I use tension control systems designed specifically for paper and board to ensure delicate handling.

- Film and Foil: These materials are susceptible to stretching and damage. I employ controlled tension and precise alignment to maintain roll integrity.

- Textiles: Rewinding textiles requires specialized equipment to prevent snags and ensure even winding.

4. How do you troubleshoot common problems that arise during the rewinding process?

I follow a systematic approach to troubleshoot common rewinding problems:

- Identify the Symptom: I carefully observe the machine’s behavior and material characteristics to pinpoint the issue.

- Analyze the Cause: I investigate potential causes based on my knowledge and experience, considering factors such as tension settings, core alignment, and material characteristics.

- Implement Solutions: I apply appropriate corrective actions, such as adjusting tension, replacing worn parts, or making minor mechanical adjustments.

5. Explain the importance of safety protocols in a rewinding operation.

Safety is paramount in a rewinding operation:

- Machine Hazards: I am aware of potential hazards, such as moving parts, sharp edges, and electrical equipment, and follow established safety procedures.

- Material Handling: I use proper lifting techniques and wear protective gear to prevent injuries related to heavy materials.

- Ergonomics: I take breaks and use ergonomic tools to reduce the risk of repetitive strain injuries.

6. How do you ensure that rewound rolls meet the required specifications?

To ensure that rewound rolls meet specifications:

- Verify Roll Dimensions: I measure roll diameter, width, and length using calibrated equipment to ensure compliance with customer requirements.

- Check Roll Quality: I inspect rolls for defects such as wrinkles, tears, or uneven winding, and make adjustments to the rewinding process as needed.

- Maintain Documentation: I keep accurate records of roll measurements and quality checks for traceability and quality control purposes.

7. Describe the importance of preventative maintenance for rewinding machines.

Preventative maintenance is crucial for rewinding machines:

- Reduce Downtime: Regular maintenance helps identify and address potential issues before they cause breakdowns, minimizing downtime and production disruptions.

- Extend Machine Life: Proper maintenance ensures that all components are functioning optimally, extending the machine’s lifespan and reducing the need for costly repairs.

- Enhance Safety: By maintaining machines in good condition, I minimize the risk of accidents and injuries in the workplace.

8. How do you prioritize tasks and manage your workload in a fast-paced rewinding environment?

To manage my workload efficiently:

- Prioritize Tasks: I identify critical tasks that impact production and focus on completing them first.

- Plan Ahead: I anticipate potential bottlenecks and plan my schedule accordingly, ensuring timely completion of tasks.

- Delegate Responsibilities: When necessary, I delegate tasks to other team members to distribute the workload and meet deadlines.

9. What strategies do you use to improve your efficiency and productivity as a rewinder operator?

To enhance my efficiency and productivity:

- Optimize Machine Settings: I continuously monitor machine performance and make adjustments to optimize speed, tension, and alignment.

- Utilize Technology: I leverage automation tools and software to streamline tasks and reduce manual intervention.

- Streamline Workflow: I identify and eliminate bottlenecks in the rewinding process, improving overall efficiency.

10. How do you stay updated on the latest rewinding techniques and industry best practices?

To stay abreast of industry advancements:

- Attend Industry Events: I participate in workshops, conferences, and trade shows to learn about new technologies and best practices.

- Read Trade Publications: I subscribe to industry magazines and journals to stay informed about the latest developments.

- Seek Continuing Education: I enroll in online courses and training programs to enhance my knowledge and skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rewinder Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rewinder Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rewinder Operators play a crucial role in the manufacturing industry by operating and maintaining rewinding machines. Their primary responsibilities include:

1. Machine Operation and Maintenance

Rewinder Operators are responsible for starting, stopping, and monitoring rewinding machines. They ensure that the machines are running smoothly and efficiently, adjusting settings as needed.

- Load and unload rolls of material from the rewinder

- Inspect materials for defects and damage

- Perform regular maintenance and repairs on the rewinder

2. Quality Control

Rewinder Operators are responsible for maintaining the quality of the rewound material by:

- Inspecting the material for defects

- Maintaining consistent tension and speed during winding

- Ensuring the material meets specifications

3. Material Handling

Rewinder Operators may also be responsible for handling the materials being rewound. This may include:

- Loading and unloading rolls of material onto the rewinder

- Packaging and labeling finished products

- Operating forklifts or other equipment to move materials

4. Safety and Compliance

Rewinder Operators are responsible for maintaining a safe and compliant work environment. They follow safety protocols and keep the work area clean and organized.

- Wear appropriate safety gear

- Follow established safety procedures

- Maintain a clean and organized work area

Interview Tips

Preparing effectively for your interview can significantly increase your chances of success. Here are some tips to help you ace your Rewinder Operator interview:

1. Research the Company and Position

Before the interview, thoroughly research the company and the Rewinder Operator position. This will help you understand the company’s culture, values, and the specific requirements of the role.

- Visit the company’s website and social media pages

- Read recent news and articles about the company

- Review the job description and identify the key skills and experience they are seeking

2. Practice Your Answers

Take time to practice your answers to common interview questions. This will help you feel more confident and articulate during the interview. Consider the following questions and prepare your responses:

- Tell me about your experience operating rewinding machines

- How do you ensure the quality of the materials you rewind?

- What is your approach to safety in the workplace?

3. Highlight Your Skills and Experience

During the interview, emphasize your relevant skills and experience. Use specific examples to demonstrate your proficiency in operating rewinding machines, maintaining quality standards, and handling materials.

- Quantify your accomplishments whenever possible

- Use the STAR method (Situation, Task, Action, Result) to structure your answers

- Relate your skills and experience to the specific requirements of the Rewinder Operator position

4. Ask Informed Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions that demonstrate your knowledge of the industry and the company.

- What are the company’s plans for growth and expansion?

- What are the opportunities for advancement within the organization?

- How does the company value safety and employee well-being?

Next Step:

Now that you’re armed with the knowledge of Rewinder Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Rewinder Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini