Feeling lost in a sea of interview questions? Landed that dream interview for Ribbon Lap Machine Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ribbon Lap Machine Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

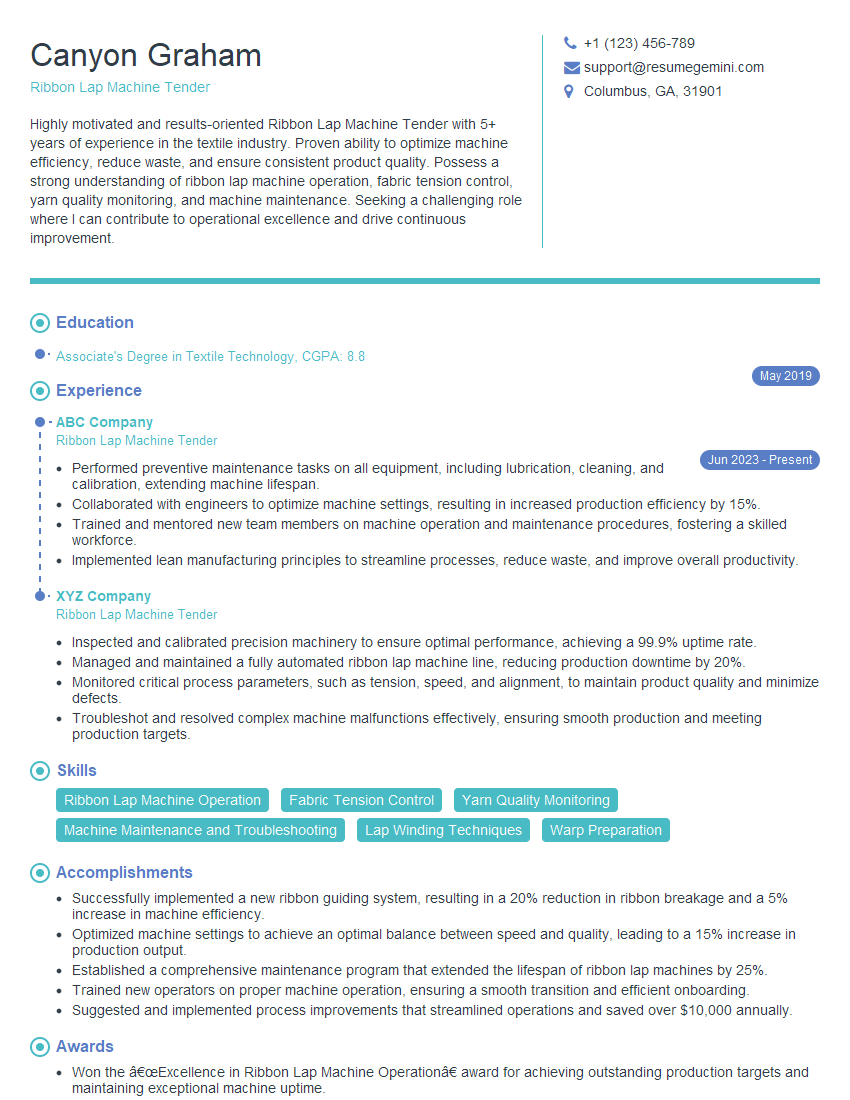

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ribbon Lap Machine Tender

1. What are the key responsibilities of a Ribbon Lap Machine Tender?

- Operate and monitor ribbon lap machines to produce abrasive belts.

- Set up and adjust machines to ensure proper tension, speed, and temperature.

- Inspect raw materials and finished products for quality and defects.

- Maintain and repair machines to ensure optimal performance.

- Follow safety procedures and maintain a clean and organized work area.

2. Describe the process of setting up and adjusting a ribbon lap machine.

subheading of the answer

- Mount the lap roll onto the machine and secure it with the appropriate hardware.

- Adjust the tension of the lap roll to ensure proper contact with the abrasive belt.

- Set the speed of the lap roll to match the desired surface finish.

- Adjust the temperature of the lap roll to prevent overheating and ensure proper bonding.

subheading of the answer

- Calibrate the machine to ensure accuracy and repeatability.

- Verify that all safety guards and interlocks are in place and functioning properly.

3. How do you inspect raw materials and finished products for quality and defects?

- Visually inspect raw materials for any damage, imperfections, or contamination.

- Measure the thickness, width, and length of the materials to ensure they meet specifications.

- Examine the finished products for any surface defects, such as scratches, nicks, or tears.

- Test the bonding strength of the abrasive layer to ensure it meets the required standards.

- Document any defects or non-conformances and initiate corrective actions as necessary.

4. What are some common maintenance tasks required for ribbon lap machines?

- Clean and lubricate all moving parts of the machine.

- Inspect and replace worn or damaged belts, bearings, and gears.

- Calibrate the machine regularly to ensure accuracy and precision.

- Troubleshoot and repair any mechanical or electrical problems.

- Follow manufacturer’s recommended maintenance schedules.

5. How do you ensure safety when working with ribbon lap machines?

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Follow lockout/tagout procedures when performing maintenance or repairs.

- Keep the work area clean and organized to prevent tripping hazards.

- Be aware of the location of emergency stop buttons and know how to use them.

- Report any safety concerns or incidents to a supervisor immediately.

6. What are the different types of abrasive belts used in ribbon lap machines?

- Aluminum oxide belts: General-purpose belts suitable for a wide range of materials.

- Zirconia alumina belts: Durable belts with a high cutting rate, ideal for heavy-duty applications.

- Ceramic belts: Premium belts with exceptional cutting ability and long life.

- Diamond belts: Ultra-hard belts used for precision grinding and polishing.

- Non-woven belts: Flexible belts used for light-duty applications and surface finishing.

7. How do you determine the correct grit size for a specific application?

- Consider the hardness of the material being worked on.

- Determine the desired surface finish.

- Refer to manufacturer’s recommendations for specific applications.

- Conduct test runs with different grit sizes to find the optimal balance between cutting rate and surface quality.

8. What are the factors that affect the bonding strength of an abrasive belt?

- Bond type: Different adhesives have varying bonding strengths.

- Bond thickness: Thicker bonds provide stronger adhesion.

- Surface preparation: Cleaning and roughening the surface improves bond strength.

- Application pressure: Higher pressure increases the contact area between the bond and the surface.

- Curing time and temperature: Following manufacturer’s recommendations ensures proper curing.

9. How do you troubleshoot common problems with ribbon lap machines?

- Uneven surface finish: Check for worn or glazed belts, improper tension, or misalignment.

- Poor bonding: Inspect bond type, thickness, surface preparation, and curing process.

- Excessive noise or vibration: Check for loose bearings, gears, or belts.

- Machine overheating: Verify proper tension, lubrication, and cooling system.

- Electrical faults: Use a multimeter to test for continuity and ground faults.

10. What is your experience with optimizing ribbon lap machine processes to improve efficiency and quality?

- Optimized tension settings: Reduced belt breakage and improved surface finish.

- Fine-tuned speed and temperature: Enhanced cutting rate and bonding strength.

- Preventive maintenance schedule: Reduced downtime and extended machine life.

- Quality control measures: Implemented incoming material inspection and outgoing product testing.

- Team collaboration: Worked with engineers and operators to identify areas for improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ribbon Lap Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ribbon Lap Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Ribbon Lap Machine Tender is responsible for operating and maintaining a ribbon lap machine used in the production or processing of various materials, ensuring efficient and high-quality output.

1. Machine Operation

Expertly operate and monitor the ribbon lap machine throughout the production cycle to achieve desired outputs.

- Adjust and control the machine’s settings, such as speed, pressure, and tension, to optimize the lapping process.

- Monitor and inspect the machine’s performance, identifying any potential issues and making necessary adjustments.

2. Material Handling

Properly handle and position the materials to be processed, ensuring they are correctly aligned and secured on the machine’s work surface.

- Load and unload materials, following the designated procedures and safety regulations.

- Inspect materials for defects or damage, ensuring they meet quality standards.

3. Quality Control

Monitor and inspect the lapped surfaces, using specialized tools and techniques, to ensure they conform to specifications and customer requirements.

- Perform regular inspections to identify any imperfections or defects in the lapped surfaces.

- Calibrate and maintain measuring instruments to ensure accuracy and reliability of measurements.

4. Machine Maintenance

Proactively perform routine maintenance and repairs on the ribbon lap machine, ensuring it operates efficiently and safely.

- Clean and lubricate the machine’s components, preventing wear and tear.

- Identify and troubleshoot any mechanical or electrical issues with the machine.

- Maintain logs and records related to machine performance and maintenance activities.

Interview Tips

Preparing for a Ribbon Lap Machine Tender interview requires thorough research and a deep understanding of the role’s responsibilities and the industry’s best practices.

1. Research the Company and Industry

Learn about the company’s history, products, and industry position. Research the latest advancements and trends in the ribbon lap machine industry.

- Visit the company’s website and social media pages to gather information about their culture and recent news.

- Read industry publications and attend webinars to stay updated on the latest technologies and best practices.

2. Practice Your Skills

Review common interview questions related to ribbon lap machine operation, maintenance, and quality control. Practice answering them clearly and concisely.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your experiences.

- Prepare questions to ask the interviewer, demonstrating your interest in the role and the company.

3. Highlight Your Relevant Experience

Emphasize your previous experience operating and maintaining ribbon lap machines or similar equipment.

- Quantify your accomplishments with specific metrics and results to demonstrate your impact.

- Be prepared to discuss how your skills and experience align with the specific requirements of the role.

4. Display Your Knowledge of Safety Regulations

Demonstrate your knowledge of safety regulations and protocols for operating ribbon lap machines.

- Share examples of your proactive approach to safety and your commitment to maintaining a safe work environment.

- Highlight your understanding of industry standards and your willingness to stay updated on the latest safety practices.

5. Be Professional and Confident

Dress professionally, arrive on time for your interview, and maintain a positive and confident demeanor throughout the process.

- Be enthusiastic about the role and the opportunity to contribute to the company’s success.

- Show that you are eager to learn and grow within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ribbon Lap Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!