Feeling lost in a sea of interview questions? Landed that dream interview for Rig Hand but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Rig Hand interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

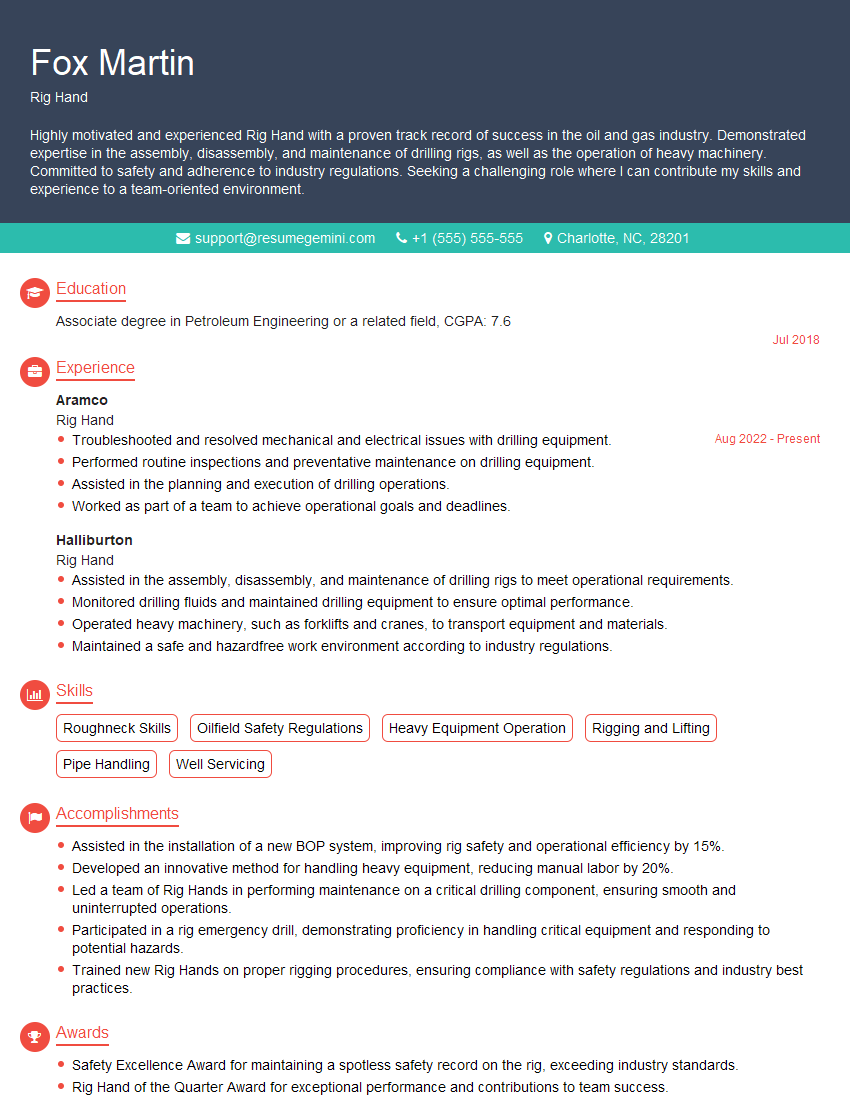

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rig Hand

1. Explain the importance of using proper personal protective equipment (PPE) on a drilling rig?

Proper use of personal protective equipment (PPE) is essential to ensure the safety of rig workers and to minimize the risk of accidents and injuries on a drilling rig.

- PPE helps to protect workers from hazards such as falling objects, hazardous chemicals, noise, and electrical dangers.

- By wearing appropriate PPE, workers can reduce their exposure to these hazards and minimize the risk of injury or illness.

- PPE can also help to improve visibility and communication among workers, especially in noisy or visually cluttered environments.

2. What are the key components of an effective fall protection system?

Fall Arrest System

- Full-body harness

- Energy absorber

- Connecting device (lanyard)

- Anchor point

Work Positioning System

- Positioning belt or harness

- Positioning lanyard

- Anchor point

Fall Restraint System

- Positioning belt or harness

- Fall restraint lanyard

- Anchor point

3. Describe the different types of lifting equipment used on a drilling rig?

There are several types of lifting equipment used on a drilling rig, each designed for specific tasks and load capacities.

- Cranes: Used for heavy lifting operations, such as moving drill pipe and casing.

- Forklifts: Used for moving materials and equipment around the rig site.

- Hoists: Used for lifting and lowering loads, such as tools and equipment, in and out of the derrick.

- Gin poles: Used for lifting and positioning lighter loads, such as electrical equipment.

- Slings: Used to connect and secure loads to lifting equipment.

4. Explain the importance of maintaining a clean and organized work area on a drilling rig?

Maintaining a clean and organized work area on a drilling rig is crucial for safety and efficiency.

- A clean and organized work area reduces the risk of slips, trips, and falls, which are common causes of accidents on a rig.

- It also improves visibility and access to equipment and materials, making it easier for workers to perform their tasks safely and efficiently.

- A clean and organized work area also reduces the risk of equipment damage and downtime, as well as the risk of environmental contamination.

5. What are the key safety considerations when working with high-pressure fluids on a drilling rig?

Working with high-pressure fluids on a drilling rig requires strict adherence to safety protocols to prevent accidents and injuries.

- Always wear appropriate PPE, including chemical-resistant gloves, eye protection, and protective clothing.

- Ensure that all equipment and connections are properly rated for the pressure and temperature of the fluids being used.

- Never attempt to repair or disconnect a pressurized line.

- Always bleed off pressure before disconnecting any lines.

- Be aware of the location of emergency shut-off valves and know how to operate them.

6. Describe the procedures for handling and storing hazardous materials on a drilling rig?

Handling and storing hazardous materials on a drilling rig requires strict adherence to regulations and best practices to minimize the risk of accidents, injuries, and environmental contamination.

- Always follow the manufacturer’s instructions and MSDS (Material Safety Data Sheet) for each hazardous material.

- Store hazardous materials in designated and properly labeled areas.

- Ensure that containers are sealed and in good condition.

- Never mix incompatible chemicals.

- Have spill kits and emergency response equipment readily available.

- Provide training to all personnel involved in handling hazardous materials.

7. Explain the role of a rig hand in maintaining the cleanliness and functionality of equipment on a drilling rig?

Rig hands play a crucial role in maintaining the cleanliness and functionality of equipment on a drilling rig.

- Regularly clean and inspect equipment to identify and address any issues promptly.

- Lubricate moving parts and ensure that all equipment is properly maintained according to manufacturer’s specifications.

- Report any damage or malfunctions to supervisors and ensure that equipment is repaired or replaced as necessary.

- Maintain a clean and organized work area to minimize the risk of accidents and injuries.

8. Describe the communication protocols and procedures used on a drilling rig to ensure safety and efficiency?

Effective communication is essential for safety and efficiency on a drilling rig.

- Establish clear communication channels and protocols for different situations (e.g., normal operations, emergencies).

- Use hand signals, radios, and other communication devices to convey information clearly and accurately.

- Ensure that all personnel are familiar with and adhere to communication protocols.

- Encourage active listening and feedback to ensure that messages are understood and acknowledged.

- Maintain a respectful and professional communication environment.

9. Explain the importance of teamwork and cooperation on a drilling rig?

Drilling operations require a high level of teamwork and cooperation among rig hands and other crew members.

- Teamwork ensures that tasks are completed safely, efficiently, and according to plan.

- Cooperation fosters a positive and supportive work environment, which contributes to overall productivity and morale.

- Effective teamwork involves clear communication, mutual respect, and a willingness to support and assist each other.

10. Describe the different types of emergencies that can occur on a drilling rig and the procedures for responding to them?

Drilling rigs can face various types of emergencies, and it is essential to have well-established procedures in place to respond effectively.

- Fire: Evacuate the rig, activate fire alarms, and use appropriate fire extinguishers.

- Blowout: Close the blowout preventer, evacuate the rig, and notify the appropriate authorities.

- Man overboard: Throw life jackets and alert the crew to begin search and rescue operations.

- Medical emergency: Provide first aid, stabilize the victim, and evacuate them to shore for further medical attention.

- Environmental spill: Contain the spill, notify the appropriate authorities, and implement cleanup procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rig Hand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rig Hand‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rig Hands play a vital role in the day-to-day operations of drilling rigs, ensuring safety and efficiency. Their primary responsibilities include:

1. General Rig Maintenance

Rig Hands are responsible for maintaining the cleanliness and organization of the rig, including keeping floors clean, tools and equipment organized, and hazardous materials properly stored.

- Maintain and clean drilling rig equipment and machinery.

- Perform daily equipment inspections and routine maintenance tasks.

2. Equipment Operation

They operate and maintain a variety of drilling equipment, including mud pumps, draw works, and rotary tables.

- Operate drilling equipment according to established procedures.

- Monitor and maintain equipment performance and make necessary adjustments.

3. Material Handling

Rig Hands are responsible for handling and moving materials such as drill pipes, casing, and mud. They also assist in loading and unloading supplies and equipment.

- Load, unload, and transport drilling materials and equipment.

- Operate cranes and other heavy machinery for material handling.

4. Safety and Emergency Response

Rig Hands are trained in safety procedures and are responsible for maintaining a safe work environment. They are also trained to respond to emergencies, such as fires, spills, and accidents.

- Follow established safety protocols and procedures.

- Respond to emergencies and assist in implementing emergency response plans.

Interview Tips

To ace an interview for a Rig Hand position, it’s important to prepare thoroughly and demonstrate your relevant skills and experience. Here are some tips to help you prepare:

1. Research the Company

Familiarize yourself with the company’s operations, industry reputation, and recent news. This shows that you’re interested and invested in the position.

- Visit the company’s website and social media pages.

- Read industry publications and news articles about the company.

2. Highlight Relevant Experience

Emphasize your hands-on experience in drilling operations, equipment maintenance, and material handling. Quantify your accomplishments with specific examples and metrics.

- Describe your involvement in drilling projects and highlight your contributions.

- Discuss your experience with operating and maintaining drilling equipment.

3. Showcase Safety Awareness

Rig Hands are responsible for maintaining a safe work environment. Emphasize your understanding of safety protocols and your experience in responding to emergencies.

- Explain your knowledge of industry safety regulations.

- Describe your experience in conducting safety inspections and implementing safety measures.

4. Demonstrate Teamwork Skills

Rig Hands work in close collaboration with other team members. Emphasize your ability to work effectively in a team environment, communicate clearly, and contribute to the team’s success.

- Discuss your experience working on drilling crews and collaborating with other members.

- Highlight your ability to follow instructions and work independently.

5. Dress Professionally

First impressions matter. Dress professionally for your interview, even if the work environment is casual. This shows that you respect the opportunity and are serious about making a good impression.

- Wear clean, pressed clothing that is appropriate for an office setting.

- Avoid wearing jeans, t-shirts, or athletic shoes.

6. Practice Common Interview Questions

Prepare for common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to ensure they are clear, concise, and relevant to the job.

- Review common interview questions and prepare your answers in advance.

- Ask a friend or family member to conduct a mock interview with you.

7. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions to demonstrate your interest in the position and the company. This shows that you’re engaged and eager to learn more.

- Ask about the company’s culture, training opportunities, or career advancement prospects.

- Inquire about the specific responsibilities of the Rig Hand role.

8. Follow Up

After the interview, send a thank-you note to the interviewer within 24 hours. This shows that you appreciate their time and are still interested in the position.

- Thank the interviewer for their time and consideration.

- Reiterate your interest in the position and the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rig Hand role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.